Ruukki Steel Pipes - Schedule 40 Seamless Carbon Steel Pipe 12Cr1MoV CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

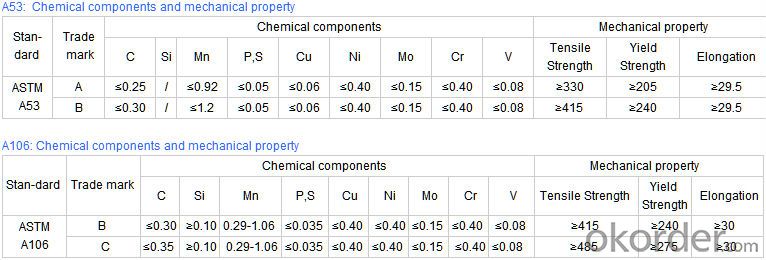

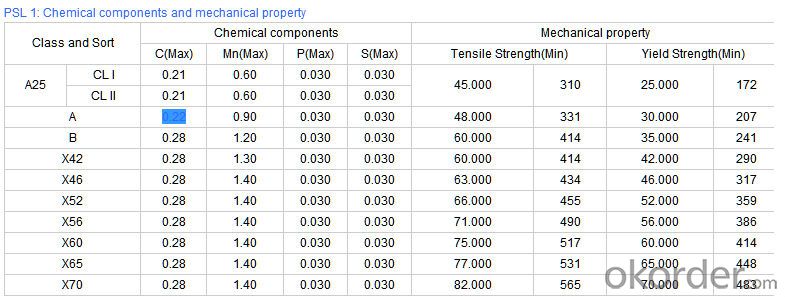

Technical Parameters of Seamless Steel Pipe

- Q:How much is the tube?

- The first prerequisite we need to determine is: what are the specifications of the steel pipe mentioned? Such as the commonly used steel pipe specifications: diameter 108*4.5, diameter 219*6, diameter 377*10, diameter and wall thickness of steel pipe with different specifications, different weight, so the steel price per meter is different.

- Q:What does "steel pipe SC" mean?

- SC (run in welded steel duitconSC is the line laying mode GB letter of wire is worn steel pipe laying (welded steel pipe, low pressure fluid) SC70 said the conductor by low pressure fluid DN70 welded steel pipe as protection pipe laying, DN70 said the nominal pipe diameter is 70mm, the nominal pipe diameter is 70mm (a series of values, the actual diameter slightly different).

- Q:What are the different joining methods for steel pipes?

- There are several different joining methods for steel pipes, including welding, threading, flanging, and mechanical coupling.

- Q:Can steel pipes be used for telecommunications cables?

- Steel pipes are not appropriate for telecommunications cables. Typically, fiber optic or copper materials are used for telecommunications cables. Steel pipes serve different purposes in construction and plumbing, but they are not suitable for transmitting data or electrical signals. Fiber optic cables are specifically designed to carry high-speed data over long distances, while copper cables are utilized for transmitting both data and electrical signals. Unlike steel pipes, these cables possess specific insulation and shielding properties required for telecommunications purposes.

- Q:What are the different types of steel pipe bends for pipeline routing?

- There are several different types of steel pipe bends commonly used for pipeline routing. These include 90-degree bends, 45-degree bends, and custom bends with specific angles as per the pipeline design requirements. Each type of bend serves a specific purpose in redirecting the flow of fluids or gases through the pipeline while maintaining structural integrity.

- Q:What are the different standards for steel pipes?

- Steel pipes are subject to various standards that guarantee their quality and compatibility in different applications. Some commonly used standards include: 1. ASTM (American Society for Testing and Materials): In the United States, ASTM standards are extensively used to specify different types of steel pipes, such as seamless and welded pipes. These standards cover dimensions, mechanical properties, and general requirements for steel pipes. 2. API (American Petroleum Institute): API standards are specifically tailored for the oil and gas industry. They provide guidelines for manufacturing, testing, and inspecting steel pipes used in oil and gas exploration, production, and transportation. 3. DIN (Deutsches Institut für Normung): DIN standards are widely adopted in Europe and outline specifications for various steel pipe types, including seamless, welded, and cast iron pipes. These standards cover dimensions, materials, and technical delivery conditions for steel pipes used across industries. 4. BS (British Standards): In the United Kingdom, BS standards are widely utilized for steel pipes in construction, engineering, and other sectors. They provide guidelines for dimensions, materials, and manufacturing processes for steel pipes. 5. JIS (Japanese Industrial Standards): JIS standards are extensively used in Japan and define specifications for different types of steel pipes, including seamless, welded, and cast iron pipes. These standards cover dimensions, materials, and technical delivery conditions for steel pipes used in various industries. 6. ISO (International Organization for Standardization): ISO standards are globally recognized and provide specifications for steel pipes used in diverse industries. They cover dimensions, materials, testing, and quality control requirements for steel pipes. It is crucial to note that specific industries and applications may have unique requirements. Therefore, it is essential to refer to the relevant standard for each specific use case. Complying with these standards ensures the safety, reliability, and compatibility of steel pipes in their respective applications.

- Q:Where is the difference between seamless steel pipe and welded pipe?

- The steel tube is a hollow steel strip, used as pipe conveying fluid, such as oil, gas, water, gas, steam, in addition, the bending and torsional strength of the same, the weight is light, so it is widely used in the manufacture of machinery parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns, shells and so on.Pipe classification: steel pipe seamless steel pipe and welded steel pipe (tube) two categories. It can be divided into round tube and special-shaped tube according to the sectional shape. The round steel tube is widely used, but there are some special-shaped steel tubes such as square, rectangle, semicircle, hexagon, equilateral triangle and octagon.

- Q:Can steel pipes be used for water supply lines?

- Yes, steel pipes can be used for water supply lines. Steel pipes are durable and have high tensile strength, making them suitable for carrying water. However, it is important to ensure that the steel pipes are properly treated to prevent corrosion and rusting.

- Q:Can steel pipes be used for geothermal energy systems?

- Yes, steel pipes can be used for geothermal energy systems. Steel pipes are commonly used for their durability and resistance to high temperatures, making them suitable for transporting hot water or steam in geothermal energy systems. Additionally, steel pipes have excellent corrosion resistance, which is crucial for geothermal environments that often contain corrosive substances.

- Q:Are steel pipes suitable for structural applications?

- Indeed, steel pipes prove to be appropriate for structural applications. Renowned for their strength, durability, and versatility, steel pipes emerge as an ideal choice for diverse structural purposes. They can be utilized in constructions, bridges, stadiums, and other edifices to provide essential support and stability. Steel pipes exhibit remarkable tensile strength, enabling them to withstand substantial burdens and resist deformation when subjected to pressure. Moreover, their resistance to corrosion renders them dependable for structural applications, even in severe environments. The utilization of steel pipes in structural applications is further amplified by their cost-effectiveness and ease of installation. In summary, owing to their strength, durability, versatility, and cost-effectiveness, steel pipes remain a favored option within the construction industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ruukki Steel Pipes - Schedule 40 Seamless Carbon Steel Pipe 12Cr1MoV CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords