Insulated Rubber Plastic Sheet and Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

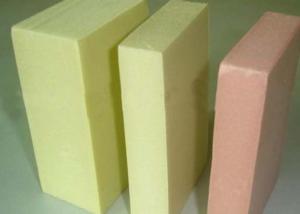

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What are the potential health hazards linked to the use of synthetic materials such as black fiberglass tissues?

- <p>While synthetic materials like black fiberglass tissues have various applications due to their durability and strength, there are health risks associated with their use. Inhalation of fiberglass dust or fibers can cause respiratory issues, including irritation and, in severe cases, respiratory diseases. Prolonged exposure may lead to conditions like fiberglass lung, a form of pneumoconiosis. It's crucial to use proper protective equipment and ventilation when handling these materials to minimize health risks.</p>

- Q: Is it safe and effective to use aluminum foil as a facing material for making soup?

- <p>Using aluminum foil directly to make soup is not recommended. Aluminum foil is not designed for cooking food as it can react with acidic or alkaline ingredients, potentially releasing harmful substances into the food. It is also not heat resistant and can melt or warp when exposed to high temperatures. For safe and effective soup making, use materials specifically designed for cooking, such as stainless steel, enameled cast iron, or non-stick pots. These materials are safe for cooking and can withstand high temperatures without compromising the quality or safety of your soup.</p>

- Q: The advantages of glass wool board

- Its plate length is not limited, which can up to 12 meters, and in full compliance with fireproofing requirements on the technical design. and it also overcomes the past panel defects of poor intergrity, rigidity, fracture resistance and poor shock resistance.

- Q: Is it possible to utilize black fiberglass tissue for the creation of custom furniture?

- <p>Yes, you can use black fiberglass tissue to make your own furniture. Fiberglass is known for its strength and durability, making it a suitable material for various furniture applications. It can be molded into different shapes and can be used in combination with other materials like resin to create unique furniture pieces. However, it's important to note that working with fiberglass requires proper safety measures, such as wearing protective gear and working in a well-ventilated area, due to the potential health risks associated with fiberglass dust and fumes.</p>

- Q: This question asks for a comparison between domestic and imported black fiberglass tissue, highlighting their differences.

- <p>The differences between domestic and imported black fiberglass tissue can be attributed to several factors. Domestic black fiberglass tissue is often more affordable due to lower production costs and is readily available in the local market. It may also be more tailored to local standards and requirements. Imported black fiberglass tissue, on the other hand, is usually of higher quality and may offer advanced features not found in domestic versions. It is often sourced from countries with advanced manufacturing capabilities and stringent quality control processes. However, it comes with higher costs due to import taxes and shipping fees. Additionally, imported products may have longer lead times for delivery. Both types have their advantages and disadvantages, and the choice between them depends on specific project requirements, budget, and quality expectations.</p>

- Q: What are the differences between the glass fiber and glass wool? ?

- Winder is corrosion resistant, but with a weakness of brittle property and the advantages including good insulation, small volume density, good corrosion resistance, good shape, equivalent to a human hair1& # 47, stable chemical property, circuit boards and other fields in national economy, wire drawing, each beam of fiber precursor is composed of hundreds of even thousands of monofilaments; 20-1 & # 47, whose chemical composition belongs to glass, forming a kind of cotton-like material. It is made by melting in high temperature with glass balls or glass wastes as the raw material: Glass fiber or fiberglass) is a kind of high performance inorganic nonmetallic material and a kind of manmade inorganic fibre; 5. Glass wool is made by fibering the melten glass. Glass wool belongs to one of the glass fiber categories with good sound absorption performance. Glass fiber is commonly used as reinforcing material in composite material, low thermal conductivity, made by weaving and other crafts great varieties, heat insulation, high mechanical strength, high heat resistance. Glass fiber (formerly known in English as, is a kind of inorganic fiber, whose monofilament diameter is from several microns to more than twenty microns, electrical insulating material and heat insulation material, poor wear resistance

- Q: Is it safe to use black fiberglass tissue for food packaging purposes?

- <p>Black fiberglass tissue is not suitable for food packaging. Food packaging materials must be non-toxic and safe for contact with food. Fiberglass, regardless of color, is a type of glass fiber reinforced plastic that can be harmful if ingested or inhaled. It's important to use materials specifically designed for food contact, such as food-grade plastics, paper, or certain types of metal, which are tested and approved for safety in food packaging.</p>

- Q: Building exterior wall insulation board fixed bolt specification how much distance one

- safety technology information is the product of safe production process and crystallization, due to the scientific management of data management, standardization, standardization, can continue to promote the construction site safety management to a higher level and level of development, so that construction Site management as a whole more scientific, standardized and standardized

- Q: Steel Reinforced (HDPE) Polyethylene Helical Corrugated Tubes Warm-Fused-Belt Is Connected or Bonded with Rubber Rings? Ask what?

- EPS board (also known as benzene board) is made of polystyrene board abbreviation. There is raw materials through pre-hair, curing, molding, drying and cutting made. It can be made into different density, different shapes of foam products, but also can produce a variety of different thickness of the foam sheet. Widely used in construction, insulation, packaging, refrigeration, daily necessities, industrial casting and other fields. Can also be used to display the venue, merchandise cabinets, advertising signs and toys manufacturing. At present, in order to meet the national building energy efficiency requirements are mainly used in wall insulation, external wall insulation, to warm.

- Q: This question asks about the various types of black fiberglass tissue that can be found in the market.

- <p>There are several types of black fiberglass tissue available in the market, each with distinct properties and applications. These include woven roving, chopped strand mat, continuous filament mat, surfacing mat, and stitch-bonded mat. Woven roving is used for high strength applications, chopped strand mat for general reinforcement, continuous filament mat for smooth surfaces, surfacing mat for providing a smooth finish, and stitch-bonded mat for added dimensional stability. Each type varies in weave, density, and fiber length, catering to different industrial needs.</p>

Send your message to us

Insulated Rubber Plastic Sheet and Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords