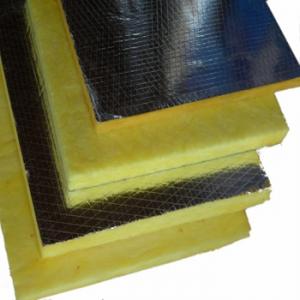

Glass Wool China Board

- Loading Port:

- China Xingang

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*40HC pc

- Supply Capability:

- 100000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Glass wool board

Width: 600, 1000,1200mm

Length: 600,1200,2300mm

Thickness: 25-100mm

Density: 24-96kg/m3

Thermal conductivity: 0.034-0.048W/mK

Average Fiber dia.:less than 7

Grade of combustibility:Non combustible Grade A

Hydrophobicity:More than 98.2%

Applications of Glass wool board

It is mainly used for the separating wall in the high-grade building, ceiling, air conduit or inner wall of bellows for thermal insurance, or machine shops for noise absorption, or metal ceiling for control of moisture.

Packaging of Glass wool board

Packed with plastic bag.

- Q: who knows the construction technology of glass?wool?board?

- Glass wool board can be made inot acoustic ceiling panels or acoustic wall panels after processing. Generally It uses glass?wool?board of 80-120kg/m3 that has undergone the curing process by glue and then will be wrapped by fireproof fabric. It is nicelooking and easy to install. common size of 1.2m × 1.2m, 1.2m × 0.6m, 0.6m × 0.6m, a thickness of 2.5cm or 5cm. the glass wool 110Kg / m3 directly sprayed acoustic ceiling panels decorative material. Whether it is glass wool acoustic wall panels or acoustic ceiling panels, they both require the glass wool of high unit weight. It also undergoes intensifying process to avoid deformation or oversoftness. This type of building materials is decorative and retains good sound absorption properties .noise reduction coefficient NRC generally can reach more than 0.85.

- Q: There is an engineering air-condition air duct which uses aluminum foil glass wool for heat conservation, supervor require that it should be added a protective layer made by glass fiber cloth. according to peremptory norms,

- 1, this problem is mainly depending on the contract you signed with the above 2, there is no clear guideline, if the owners is rich, you can coat moisture-proof layer containing sackcloth material and two layers of 25mm thick plaster protective layers on the 70mm bulk fiber heat conservation layer outside the air duct, and coat the outer edge with two layers of aluminium paint.

- Q: Where are the differences between the glass wool board and glass wool blanket?

- Glass wool felt is generally used to the top of industrial plants, which is roll-like; glass wool board is mainly used for external wall heat insulation, which is board-shaped.

- Q: Glass wool can be used at zero degrees

- There are alkali superfine glass wool felt temperature: -100 ~ 450 ℃

- Q: Do you have any recommendation about the glue used to adhere the glass wool to glass?fiber felt? Thank you.

- You can try sodium silicate (sodium metasilicate) which is used to glue cartons.

- Q: could experts tell me the producing method of insulating layer for glass?wool?board?

- If you have already taken the composite board as interior wall, you don't have to do the final construction, because the inside and outside layer of composite board have been very smooth and no defects, if you want to do surface construction, there will demand many materials, because there is no surface composite board, but only those with grooves on the market, and the groove itself is for increasing the weight and pressure bearing strength of composite board. Supplement: Glass wool composite board is metal surface fireproof?panel, it's mainly made of rock wool and glass wool, it takes high quality coating steel plate as the plane material, continuous cotton fiber, rock wool and glass wool as the core material, high-density hard foamed polyurethane as the tongue-and-groove filling, shaped after high pressure foaming solidified, automatic solid cotton cloth and controlled by the ultra-long precision double track.

- Q: What is the highest temperature that the fireproof glass?cotton can resist?

- It has good thermal insulation which is based on the thermal conductivity (λ=0.043W/m2K) of glass?wool.It also has excellent fireproof?performance and it can resist over 1000 ℃.

- Q: Does rock wool look like glass wool ?

- They are not the same. The main raw material of glass wool is glass with long thin and elastic cellosilk, while that of rock wool is basalt with short and thick rock wool silk. But both are used for thermal insulation. Glass wool is more expensive.

- Q: What are the standards of glass wool board?

- Common specifications are 1000 * 600 1200 * 600 with the thickness of 5-10cm and 3-5cm. It can be customized.

- Q: What is the construction technology of glass wool felt aluminium expanded sheet sound-absorbent wall?

- 1, Technological process: Dry laying a layer of asphalt felt →install wood keel → install gypsum board → paste glass wool felt → pave and nail a layer of glass fiber cloth → install aluminium expanded sheets → fix aluminium expanded sheets. 2, Operating points of the construction method. a, Embedded anticorrosion wood bricks: During masonry construction, laying bricks while pre-casting anticorrosion wood bricks (40 × 60 × 60), and the horizontal distance is 400 to 500 with the vertical distance of 400.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 1999 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Southeast Asia;African |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang; |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 1000,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Glass Wool China Board

- Loading Port:

- China Xingang

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*40HC pc

- Supply Capability:

- 100000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords