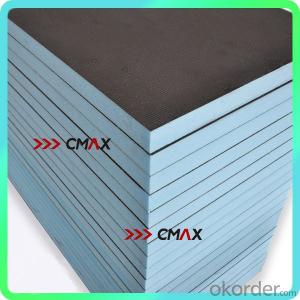

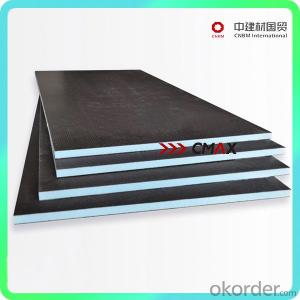

XPS Blue Board Perth - Extruded Polystyrene Insulation Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 65 Cubic Meters or more m³

- Supply Capability:

- 300 Cubic Meters per Day or more m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1. Extruded polystyrene insulation board

2. cold and heat insulation

3. sound absorption

Product introduction

XPS (extruded polystyrene) insulation board is comprised of import polyethylene and manufactured through a special plastic extruction process with high density. It is produced by environmental material, and generates no harmful gas, the leftover material can be reuse, will not be decompose and mildew, anticorrosion. It has smooth surface through extrusion, and has completely closed cell inside. This kind of material has excellent heat insulate performance, high moisture resistance, lightweight excellent compressive strengths, and anticorrosion. This is ideally use for the construction industry.

XPS insulation board has 99% closed cell rate. As a result for high heat resistance, low expand rate and low thermo conductivity. The heat insulation effect of 25mm thick XPS board is superior than 120mm thick concrete perlite. It is usually used in apartments, high-rise buildings, workshop, cold storage warehoused for heat insulation. Compare XPS with ESP, ESP is bigger in cells and loser in structure.

Specification

Density: 40, 50kg/m3

Size (L x W): 1800 X 600mm

Thickness: 20. 25. 30. 40. 50mm

Physical properties

Thermal conductivity (/m.k):<=0.028

Moisture absorption:1%

Temperature deformation: 40 -90 degree (0.6%)

Compressive strength:250kpa

Thermal resistance retention rate:10 year 80%

- Q: 25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- 2 fastener type steel pipe stent construction must be prepared before the construction program

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- Flexible ducts for rigid piping and ducts for gas pipelines for drainage pipes

- Q: How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Mainly for insulation to reduce heat loss. So use a good insulation material insulation. Hope it helps you.

- Q: Why extruded board (XPS board) is the best insulation board material

- Rong Sheng this section is quite good, the appearance of fashion, quiet, energy saving, computer temperature control, insulation effect is good

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- Think of the safety data directory to compare the trouble to compare JGJ59-2011 check the information bar

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- The best bamboo pole, or plastic, aluminum alloy, then there is no child at home can have a child, then it is dangerous to fall easily hit people

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- Extrusion insulation board b1 and b2 grade fire resistance distinction is as follows: b1 level from the fire choking level, that is, after leaving the fire automatically extinguished, or 10 seconds off. B2 level for the slow combustion level, that is, after the fire will not be larger, and the drop will not ignite the filter paper;

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- It is a white solid with a fine closed-cell structure which is heated and preformed in a mold by heating before it is made of a volatile liquid blowing agent.

- Q: Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Online under ah ~ ~! A few days ago I have a ~ ~!

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Single-row fastener type steel pipe scaffold for decoration works in the construction of small horizontal bar spacing should be the number of mm.........................................................

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | North America Eastern Europe Southeast Asia Africa Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

XPS Blue Board Perth - Extruded Polystyrene Insulation Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 65 Cubic Meters or more m³

- Supply Capability:

- 300 Cubic Meters per Day or more m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords