Insulated Rubber Plastic Sheet / Insulated Rubber Plastic Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

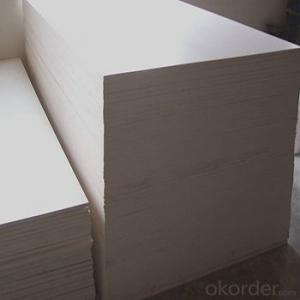

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Could centrifugal glass wool be treated as cold insulation material?

- It depends on the specific requirements, now glass wool is not allowed to use in areas with high fire rating and cold insulation requirements.

- Q: I would like to ask how the process of cryogenic treatment

- Biology: fast cooling, can prevent the crystallization of cells in the water, does not destroy the cell organization. In the preservation of sperm, organ preservation, food preservation, preservation of certain life and so onMedical treatment: cryotherapy, treatment of certain skin diseasesSpace: the space environment simulation, satellite ground test station, using liquid helium, create -200 degrees of low temperature.Noise: high sensitivity radar telescope, using liquid helium cooling, receiving device, noise reductionVacuum: the use of cold well technology can get high vacuum

- Q: What is the difference between the cement foam insulation board and the extruded board?

- Sandboard is a common product in the current building materials, not only can a very good flame retardant and environmentally friendly sandwich board English name: laminboard sandwich panel products are made of two layers of metal panels (or other material panels) and Directly in the middle of the panel foam, mature molding of the polymer core insulation composition These sandwich panels are easy to install, lightweight and efficient Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor [1] The formation of the outer steel plate takes full account of the structural and strength requirements, and take into account the aesthetic, the inner layer of the formation of flat to meet the needs

- Q: Is it safe or advisable to use aluminum foil with a reflective side to wrap vegetables?

- <p>Yes, you can use aluminum foil facing to wrap vegetables. Aluminum foil is commonly used in cooking for wrapping, storing, and cooking food, including vegetables. The reflective side of the foil can actually help in heat distribution and may aid in cooking the vegetables more evenly. However, it's important to ensure that the foil does not come into direct contact with any part of the vegetable that could be damaged by heat, and to avoid using foil with non-stick coatings on it, as these can deteriorate at high temperatures. Always follow safety guidelines for using aluminum foil in cooking.</p>

- Q: What is the function of glass wool foil?

- Glass wool is one kind of the glass fiber and it is a man-made inorganic fiber. Glass is made by melting such raw materials as quartz sand, limestone, dolomite and other natural ore with some chemical materials like pure alkali and sodium borate. In the molten state, the glass is thrown into fine fibers in the shape of floc by the with external force. These fibres vertically interwine and show many small gaps. These gaps can be regarded as air void. Thus, glass wool can be regarded as porous materials and it is of good insulation and sound absorption performance.

- Q: Who can tell me about the unit weight of glass wool board?

- Glass wool has a good sound absorption performance in the high-frequency sound. The main factors affecting the centrifugal glass wool' sound absorption performance are thickness, density and air flow resistance, etc. Density is the weight per cubic meter of materials. 1. with the increase of thickness, the low frequency sound absorption coefficient significantly increases, but there is little change in the high frequency (high frequency absorption is always larger). 2. thickness is the same, the unit weight increases, the low frequency sound absorption coefficient also increases; but when the unit weight increases to a certain extent, the material becomes dense, the flow resistance is greater than the optimum flow resistance, sound absorption coefficient decreases.

- Q: Foam cement insulation board is composed of cement and what materials?

- That is, you can pull the most important thing at the farthest distance. The top of the tower can move the car before and after he moves to the farthest place to pull up the heaviest weight is slightly! The The

- Q: What is the density of high-temperature glass wool ?

- Glass wool thickness 15MM 25MM 30MM 40MM 50MM they have different prices. It depends on what you are used for. Unit weight is 12K 16K 24K 32 48K Higher unit weight has to be customized.

- Q: This question asks for the distinctions between black and white fiberglass, likely in terms of their properties or applications.

- <p>Black fiberglass and white fiberglass primarily differ in their color, which is due to the pigments added during the manufacturing process. Black fiberglass often contains carbon black, which can provide better UV resistance and may be more resistant to yellowing over time. White fiberglass, on the other hand, is typically used for applications where visibility or aesthetics are important, such as in boat hulls or certain types of insulation. Functionally, both types have similar strength and durability, but the choice between black and white often comes down to specific application needs or personal preference.</p>

- Q: Is it possible to utilize black fiberglass tissue as a material for creating a floor mat?

- <p>Yes, you can use black fiberglass tissue to make a floor mat. Fiberglass is known for its strength and durability, making it a suitable material for various applications, including floor mats. However, it's important to ensure that the mat is properly treated to be non-slip and comfortable to walk on. Fiberglass can be abrasive and may not provide the softness or cushioning that some users prefer. Additionally, consider the aesthetic appeal and whether the black color is appropriate for your intended use. Always follow safety guidelines when working with fiberglass to avoid skin and respiratory irritation.</p>

Send your message to us

Insulated Rubber Plastic Sheet / Insulated Rubber Plastic Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords