FM Rubber Plastic Insulation Sheet and Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

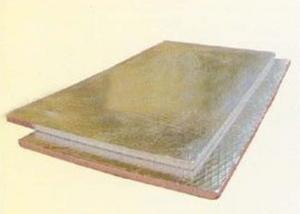

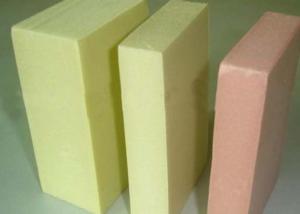

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How to convert thickness if the heat insulation effects of glass wool board and rubber and plastic board is the same?

- Calculated in accordance with the respective heat insulation layers

- Q: What are some methods to avoid aluminum foil sticking to food while cooking or baking?

- <p>Yes, there are several ways to prevent aluminum foil from sticking to food. You can lightly grease the foil with cooking spray or oil before placing the food on it. Alternatively, you can use parchment paper or a silicone baking mat between the food and the foil. Another method is to dampen the foil slightly with water, which can create a barrier. Using a non-stick aluminum foil designed for cooking can also be effective. Remember to handle the foil carefully to avoid tearing, especially when greasing or dampening it.</p>

- Q: What is the rate at which black fiberglass tissue absorbs moisture?

- <p>The moisture absorption rate of black fiberglass tissue is typically very low, often less than 1%. This low absorption rate is due to the material's hydrophobic nature and the manufacturing process that includes a resin treatment. However, specific absorption rates can vary depending on the exact composition and treatment of the fiberglass tissue, and it's advised to refer to the manufacturer's specifications for precise data.</p>

- Q: Is it possible to use black fiberglass tissue as a material for flooring?

- <p>Yes, black fiberglass tissue can be used for flooring. It is often used in commercial and industrial settings due to its durability, resistance to chemicals, and ability to withstand heavy traffic. Fiberglass tissue is a type of composite material that can be combined with resins to create a strong and stable flooring surface. However, it is important to ensure that the fiberglass tissue is properly treated and combined with the right resins to avoid any health or safety concerns.</p>

- Q: This question asks if there are any potential issues or risks associated with storing food in plastic containers for extended periods.

- <p>Yes, there are concerns about using plastic containers for long-term food storage. Certain plastics can leach chemicals, such as BPA (Bisphenol A) and phthalates, which may be harmful when ingested over time. These chemicals can migrate into the food, especially with exposure to heat or over extended periods. Additionally, plastic containers can break down over time, potentially releasing harmful substances into the food. It's recommended to use food-grade, BPA-free plastics or alternatives like glass containers for long-term storage to minimize health risks.</p>

- Q: Is it possible to use a single piece of aluminum foil for cooking or baking multiple times?

- <p>While aluminum foil is a versatile kitchen tool, it is not recommended to reuse a single piece of aluminum foil for cooking or baking multiple times. Aluminum foil can tear or become thin with use, which may compromise its effectiveness and potentially allow food to stick or contaminate the foil. Additionally, repeated use can lead to the accumulation of food particles and bacteria, posing a risk to food safety. It's best to use a fresh piece of aluminum foil for each cooking or baking session to ensure hygiene and椋熷搧瀹夊叏.</p>

- Q: Can black fiberglass tissue be utilized effectively for the purpose of window cleaning?

- <p>Yes, black fiberglass tissue can be used for cleaning windows. It is a durable and non-abrasive material that effectively removes dirt and grime without scratching the glass surface. The fine fibers can reach into small crevices and effectively clean the window. However, it's important to ensure that the fiberglass tissue is clean and free from any debris or particles that could potentially scratch the glass. Always test a small, inconspicuous area first to ensure it doesn't damage the window.</p>

- Q: What is the difference between high density glass wool board and stereoplasm rock wool board?

- The main raw material of rock wool products is fine basalt rock. The basalt rock is made into inorganic fiber after meited under high temperature and processed in the high-speed centrifugal device. he rock wool board can be made into wool board and rock wool pipe shells.Technical characteristics of rock wool board are as follows.1, good thermal insulation property, mechanical?property and fireproof?performance.2, It has high the coefficient of acidity and better chemical stability and fiber durability.3, It has good sound-absorbing performance.Rock wool is widely used for thermal insulation in boilers and equipment pipelines of petroleum, chemical, metallurgy, textile industries. It is also used for thermal insulation and sound absorption of partition,suspended ceiling, inner wall and external wall in the construction industry.Rock wool board's main products and specifications are as follows.1, the density of rock wool board:80 -180kg / m3 2, the thickness of rock wool board :50mm-100mm 3, specifications of rock wool board :1000mm × 600mm. The thickness is 10mm-100mm; the length is 1m; width is 0.63m; density is 100-220kg and diameter is 27mm-1080mm.

- Q: What are the industry standards of glass wool and its products?

- The industry standards of glass wool and its products GB / T 13350-2000. The standards specifies classification, requirements, testing methods, inspection rules, marking, labeling, packaging, transportation and storage of glass wool for thermal insulation and its products. It also give the conversion of thermal resistance and thermal conductivity coefficient. This standard applies to insulating glass wool, glass wool board, glass wool band, glass wool blanket, glass wool felt and glass wool tube.

- Q: Is it possible to utilize black fiberglass tissue as a material for facial tissues?

- <p>No, black fiberglass tissue is not suitable for use as facial tissues. Fiberglass is a type of fiber made from glass, which is rough and can be abrasive on the skin. It is commonly used for insulation and reinforcement in construction and automotive industries. Facial tissues, on the other hand, are made from soft materials like cellulose pulp from wood, which is gentle on the skin. Using fiberglass for facial tissues could cause skin irritation and is not hygienic or safe.</p>

Send your message to us

FM Rubber Plastic Insulation Sheet and Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords