Rubber Conveyor Belt EP/Nylon/CC Canvas Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Rubber Conveyor Belt EP/Nylon/CC Canvas Conveyor Belt

Description of Rubber Conveyor Belt

The polyester conveying belt is also called EP conveying belt. Its framework material is the polyester canvas interwoven with meridian terylene and latitudinal polyamide fiber. It is characterized with excellent endurance, good water-resistance, no lowering of strength in humidity, mildew-proof, and high load of initial models. It is applicable to convey materials in medium and long distance, with high-load, and at high speed.

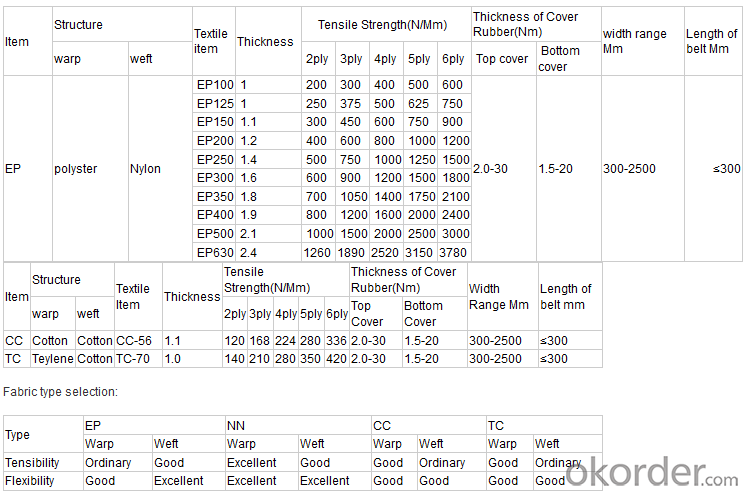

Specification of Rubber Conveyor Belt

1) Fabric: Cotton, Nylon, Polyester

2) Width: 200mm-1800mm

3) Thickness: 4mm-20mm

4) T/S: 8Mpa-24Mpa

USAGE: mining, metallurgical industry and architectural industry, ports etc.

Pictures of Rubber Conveyor Belt

Pls contact me freely if any inquiry or questions,thank you!

- Q: What solvent is used to clear the melted rubber layer?

- The acetone extractives are some fatty acids and steroids, some natural antioxidants and accelerators, and can help with the powdery agent in the process of mixing and dispersion of rubber softening effect.Ash containing mainly magnesium phosphate and calcium phosphate salts, copper, manganese, iron and other metal compounds is very small, because these valence metal ion can promote the aging of rubber, so their content should be controlled.

- Q: Excuse me, is PU one kind of silicone? Or what is the connection between the two?

- PU is the abbreviation of Polyurethane, Chinese name is polyurethane, referred to as polyurethane. Because of the simple modification of the formula, different density, elasticity, rigidity and other physical properties can be obtained. At present, a large number of glass fiber insulation materials, wood, traditional rubber products and so on.

- Q: Is mixed silicone rubber dangerous?

- With excellent thermal stability, high and low temperature resistance, can -60 to +250 DEG C under the condition of long-term work, ozone resistance, weatherability and good electrical properties, corona resistance, electric arc, electric spark is extremely strong, with chemical stability, weathering resistance, radiation resistance, physical inertia and good air permeability.

- Q: How do ordinary NBR and EPDM materials differ?

- Three EPDM (EPDM) is a non conjugated diene copolymer of ethylene and propylene and a small amount of an ethylene propylene rubber, represented by EPDM, because of its main chain is composed of saturated hydrocarbon chemical stability, only in the side chain containing unsaturated double bond, so the ozone resistance, heat resistance, weather resistance etc. aging resistance, can be widely used in automobile parts, building waterproof materials, wire and cable sheath, heat-resistant hose, rubber belt, automotive seals etc..

- Q: Rubber products on tiles, why tiles yellow?

- Rubber products generally contain operating oil, the role is to make rubber easier to process and soft. But the oil runs easily to the surface of the rubber, so it makes the tiles yellow.

- Q: How to identify the tire rubber is raw or cooked

- Rubber is a kind of polymer material with high elasticity, is the parent material manufacturing of rubber products, generally refers to the rubber unvulcanized. A nearly neutral liquid produced by a rubber tree and added with 0.05%~0.1% ammonia water to make latex (for a short period of time). Most of the latex need processed dry glue, all kinds of natural rubber is often said.

- Q: What is the composition of the vulcanizing agent for silica gel?

- Vulcanizing agent is organic peroxide, or bridging agent, used for curing silicone rubber (Xi Likang), EVA and curing of unsaturated polyester.

- Q: I do rubber products, I would like to ask what metal accessories are rubber products, the specific name is what, good, then points

- High pressure rubber tube, natural rubber tube, Shandong rubber tube, high pressure rubber tube, low pressure rubber tube, Ding Qing rubber tube, high quality rubber tube;

- Q: What are the bridge rubber air bags used for?

- After the concrete is poured, the vibrating bar is vibrated simultaneously from both sides, so as to prevent the core mold from moving to the left and the right. And the vibration bar segment head can not touch the core mold, so as not to wear and tear gas leakage.

- Q: What is the difference between PVC rubber and ordinary rubber?

- PVC has strong resistance to oxidizing agents, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, and it is also not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

Send your message to us

Rubber Conveyor Belt EP/Nylon/CC Canvas Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords