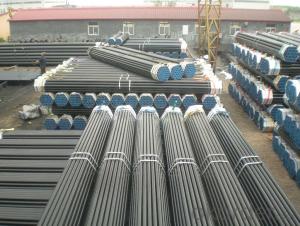

Round Steel Pipes Quotes GB ASTM A106/53 API 5L Seamless Steel Pipes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are company that have many years experience and professional manager team and engineer team and sales team, sure we will provide you high quality of pipe and professioanl service.

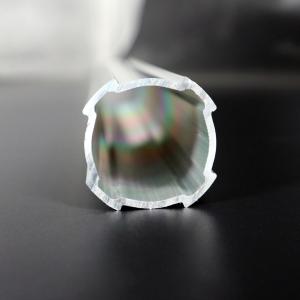

Seamless pipe possesses a hollow section and without seam around the strip steel. It is made with solid bar or steel ingot by perforating machine. As the facture process does not include any welding, seamless pipes are considered to be stronger and more durable. Generally speaking, seamless pipe has better pressure resistance and security than other classifications, and was usually more easily available than welded pipe.

2、Main Features of the Seamless Pipe:

• High working accuracy

• High strength

• Small inertia resistance

• Strong therming dissipine ability

• Good appearance

• Reasonble price

3、Seamless Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range: OD: 21.3-610mm, WT:6-70mm, length:6-12m or according to the requirement of clients.

3) Executive standards: GB, ASME API5L.ASTM A 106/A53,Despite of the above standards, we can also supply seamless steel pipe with standard of DIN, JIS, and so on, and also develop new products according to the requirements of our clients!

4) Surface: black lacquered, varnish coating or galvanized.

5) Ends: Beveled or square cut, plastic capped, painted.

6) Packing: bundles wrapped with strong steel strip, seaworthy packing.

4、Packaging & Delivery:

Packaging Details: | seaworthy package, bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe:

①How is the quality of your products?

We have many years business experience in this area, and we have professional engineer and manager team and sure we can provide you high quality production and professional service.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Seamless Pipe Images:

- Q:D108*4 what does "D108" mean by seamless steel tubes? What does "*4" mean?

- Seamless steel pipe: a pipe with a hollow cross section, used as a conduit for transporting fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials. Compared withsteel and roundsteelinsolid, flexural torsional strength in the same time, the weight is light, is a kind of economic section steel, widely used in the manufacture of structural parts and mechanical parts, such as the oil pipe, automobile transmission shaft, the bicycle frame and steel construction with scaffold with steel pipe manufacturing ring parts can be improved the utilization rate of materials, simplify the manufacturing process, material saving and working hours, has been widely used to manufacture steel tube.

- Q:What is the average lifespan of a steel pipe?

- The average lifespan of a steel pipe can vary depending on various factors such as the quality of the steel, the environment it is exposed to, and the level of maintenance. However, with proper installation and maintenance, a steel pipe can typically last anywhere from 20 to 100 years.

- Q:What are the standard specifications for steel pipes?

- The standard specifications for steel pipes vary depending on the specific application and industry requirements. However, some common standard specifications for steel pipes include dimensions, material composition, strength, and testing procedures. These standards are set by organizations such as the American Society for Testing and Materials (ASTM), the International Organization for Standardization (ISO), and other national or international bodies. It is important to consult the appropriate standard specifications for specific project needs.

- Q:How are steel pipes stored and transported?

- To ensure the safety and prevent damage of steel pipes, a systematic and efficient approach is employed for their storage and transportation. In terms of storage, designated areas are used to either horizontally or vertically stack the pipes. In the case of vertical stacking, custom-made racks or stands are utilized to provide support and prevent rolling or collapsing. This method not only saves space but also allows for easy accessibility when required. To safeguard steel pipes against corrosion and environmental elements, a layer of paint or other protective materials is often applied. Furthermore, pipes may be stored indoors in warehouses or storage facilities to shield them from unfavorable weather conditions. In terms of transportation, depending on the distance and destination, steel pipes are typically loaded onto trucks, railcars, or ships. Specialized equipment such as cranes or forklifts is employed to handle and load the pipes onto these vehicles. To prevent movement during transit, the pipes are tightly secured using straps, chains, or braces. This ensures stability and eliminates the risk of damage to the pipes themselves or other cargo. For long-distance transportation, steel pipes are often transported in bundles or stacks, reinforced to provide additional security. They may also be packed in protective coverings or containers to shield them from moisture, dust, or impacts. Overall, the storage and transportation of steel pipes necessitate meticulous planning, proper handling, and appropriate protective measures to uphold their integrity and quality throughout the entire process.

- Q:The difference between 12Cr1MoVG alloy steel tube and 15CrMo

- With this kind of steel manufacturing products, usually by heat treatment (normalizing and tempering); parts made before use, usually need to go through refining or chemical surface treatment (carburizing and nitriding), surface quenching or high-frequency quenching treatment. Therefore, according to the chemical composition (mainly carbon content), heat treatment process and use of different, such steel can be roughly divided into carburizing, quenching and tempering and nitriding steel three.

- Q:How do steel pipes handle vibrations?

- The effectiveness of handling vibrations is a well-known attribute of steel pipes. Their strong and rigid nature enables them to withstand various types of vibrations, including mechanical vibrations and seismic activities. The structural integrity and strength of steel pipes are responsible for their resilience. Steel pipes possess high tensile strength, which allows them to resist deformation or breakage when exposed to vibrations. They also exhibit resistance to fatigue, meaning they can endure repeated vibrations without suffering significant damage. This quality makes steel pipes ideal for applications involving constant or cyclic vibrations, such as in industrial settings or for fluid transportation through pipelines. Furthermore, steel pipes have the added advantage of being able to dampen vibrations due to their mass. The weight of the steel pipe aids in absorbing and dissipating the energy generated by vibrations, preventing excessive movement or oscillation. This damping effect contributes to the overall stability and durability of the pipe system. Various measures can be taken to further enhance the ability of steel pipes to handle vibrations. These measures may include the utilization of vibration isolators or dampers, which are devices designed to reduce the transmission of vibrations from the surrounding environment. Additionally, proper installation techniques and regular maintenance can help ensure that steel pipes continue to function optimally under conditions prone to vibrations. In conclusion, steel pipes possess the necessary attributes to effectively handle vibrations, including strength, resistance to fatigue, and the ability to dampen vibrations. Their robustness and durability make them a reliable choice for applications where vibrations are a concern, guaranteeing the safe and efficient transportation of fluids or materials.

- Q:What is the difference between steel pipe and PVC conduit?

- Steel pipe and PVC conduit serve distinct purposes and possess unique characteristics. The material composition stands as a primary distinction between steel pipe and PVC conduit. Steel pipe consists of robust and enduring materials, typically carbon steel or stainless steel, rendering it sturdy and resistant to impact. Consequently, it finds its utility in heavy-duty applications such as plumbing or structural support. In contrast, PVC conduit is constructed from polyvinyl chloride, a type of plastic. PVC's lightweight, flexibility, and ease of manipulation make it ideal for electrical purposes like safeguarding and directing electrical wires. Resistance to corrosion represents another disparity between the two. Steel pipe exhibits greater resistance to corrosion than PVC conduit, particularly when fortified with protective layers like zinc or epoxy. This makes steel pipe suitable for outdoor applications, subterranean installations, or environments with high moisture or corrosive elements. PVC conduit, while generally resistant to moisture and chemicals, may deteriorate over time when exposed to sunlight and can be harmed by specific chemicals. Consideration of cost becomes another factor. Steel pipe generally incurs greater expenses than PVC conduit due to its material and manufacturing process. Nonetheless, steel pipe's durability and extended lifespan establish it as a cost-effective selection in the long run, particularly for applications necessitating high strength and longevity. On the contrary, PVC conduit is comparatively inexpensive and readily accessible, rendering it a more affordable choice for numerous electrical projects. Lastly, installation methods differ between the two. Steel pipe is typically connected through threaded connections or welded joints, mandating specialized tools and skills. Conversely, PVC conduit can be effortlessly cut, assembled, and connected using PVC cement or fittings. This renders PVC conduit a more DIY-friendly option for electrical installations. In summary, steel pipe and PVC conduit diverge in terms of material composition, resistance to corrosion, cost, and installation methods. Steel pipe boasts strength, durability, and corrosion resistance, making it suitable for rigorous applications. PVC conduit, conversely, possesses lightness, flexibility, and affordability, rendering it ideal for electrical projects.

- Q:What is the production process of seamless steel tube?

- The delivery status of hot-rolled seamless steel tubes is generally hot-rolled and delivered after heat treatment. Hot rolled seamless steel tube after quality inspection after staff strict hand picked in quality inspection should be carried out after the oil surface, followed by cold drawing experiments, hot rolling process should be carried out after the perforation experiment, if perforated expanding too large to carry out straightening correction. After straightening, the device is sent to the flaw detector by the transfer device to carry out the flaw detection experiment. Finally, the label is attached and the specifications are arranged and placed in the warehouse.

- Q:Can steel pipes be used for the construction of transmission towers?

- Yes, steel pipes can be used for the construction of transmission towers. Steel pipes are commonly used in the construction industry due to their strength, durability, and ability to withstand heavy loads. They provide structural support and stability required for transmission towers, making them a suitable choice for this application.

- Q:Can steel pipes be used for underground utility lines?

- Yes, steel pipes can be used for underground utility lines. Steel pipes are commonly used for various underground applications, including utility lines for water, gas, and sewage. They are durable, strong, and resistant to corrosion, making them suitable for long-term use in underground environments. Additionally, steel pipes can be easily welded and connected, allowing for efficient installation and maintenance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Round Steel Pipes Quotes GB ASTM A106/53 API 5L Seamless Steel Pipes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords