Round Bar and Deformed Bar Grade 460A_460B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Round Bar and Deformed Bar Grade 460A_460B

Details of Round Bar and Deformed Bar Grade 460A_460B

Name | Deformed Bar |

Shape | Round Bar |

Standard | 1.GB1499.2-2007, HRB335, HRB400E 2. ASTM A615 Gr.40, Gr.60 3.BS4449/1997 |

Diameter | 6mm-50mm |

Length | 6m, 8m, 9m,12m as standard or as request |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of Round Bar and Deformed Bar Grade 460A_460B

Standard | Grade | Yield Strength Mpa | Tensile Strength | Elongation% |

BS4449:1997 | 250 | 250 | 295 | 22 |

460A | 460 | 485 | 12 | |

460B | 460 | 500 | 15 | |

GB1499.2-2007 | HRB335/335E | 335 | 455 | 17 |

HRB400/400E | 400 | 540 | 17 | |

HRB500/500E | 500 | 630 | 16 | |

ASTM A615 & A615M-04a | GRADE40 | 280 | 420 | 12 |

GRADE60 | 420 | 620 | 9 | |

GRADE75 | 520 | 690 | 7 | |

JIS G3112-2004 | SD295A | ≥ 295 | 440-600 | 17 |

SD295B | 295-390 | ≥ 440 | 17 | |

SD345 | 345-440 | ≥490 | 19 | |

SD390 | 390-510 | 560 | 17 | |

SD490 | 490-625 | ≥ 620 | 13 |

Size | WEIGHT | WEIGHT | QUANTITY | ||

LENGTH 6M | LENGTH 12M | LENGTH 6M | LENGTH 12M | ||

6 | 0.222 | 1.332 | 2.664 | 751 | 375 |

8 | 0.395 | 2.37 | 4.74 | 422 | 211 |

10 | 0.617 | 3.702 | 7.404 | 270 | 135 |

12 | 0.888 | 5.328 | 10.656 | 188 | 94 |

14 | 1.21 | 7.26 | 14.52 | 138 | 69 |

16 | 1.58 | 9.48 | 18.96 | 106 | 53 |

18 | 2 | 12 | 24 | 83 | 42 |

20 | 2.47 | 14.82 | 29.64 | 67 | 34 |

22 | 2.98 | 17.88 | 35.76 | 56 | 28 |

25 | 3.85 | 23.1 | 46.2 | 43 | 22 |

28 | 4.83 | 28.98 | 57.96 | 35 | 17 |

32 | 6.31 | 37.86 | 75.72 | 26 | 13 |

36 | 7.99 | 47.94 | 95.88 | 21 | 10 |

40 | 9.87 | 59.22 | 118.44 | 17 | 8 |

50 | 15.42 | 92.52 | 185.04 | 11 | 5 |

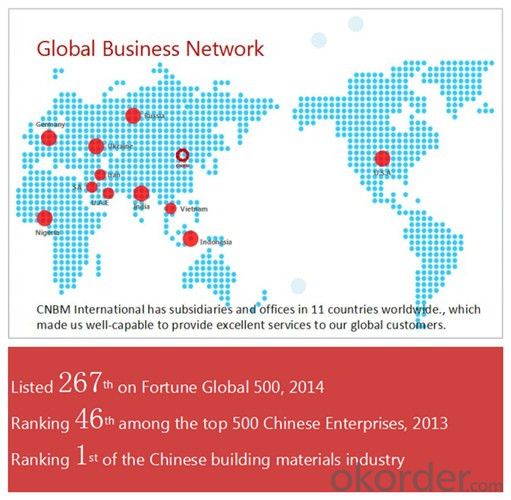

CNBM Introduction of Round Bar and Deformed Bar Grade 460A_460B Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Round Bar and Deformed Bar Grade 460A_460B

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the factors that affect the corrosion resistance of special steel?

- The factors that affect the corrosion resistance of special steel include the composition of the steel, the presence of alloying elements such as chromium and nickel, the surface finish and cleanliness, the presence of protective coatings or films, the pH and temperature of the environment, and the exposure time to corrosive agents. Additionally, the presence of impurities, such as sulfur and oxygen, can also impact the corrosion resistance of special steel.

- Q: What are the international standards for special steel?

- The international standards for special steel are a set of guidelines and specifications that ensure the quality, performance, and safety of special steel products worldwide. These standards cover various aspects such as chemical composition, mechanical properties, heat treatment, and testing methods. Examples of international standards for special steel include ISO 4957 for tool steels, ASTM A681 for high-carbon and alloy tool steels, and EN 10083 for quenched and tempered steels. Compliance with these standards helps manufacturers, suppliers, and users to meet global requirements and maintain consistency in the production and use of special steel.

- Q: What are the applications of special steel in the oil and gas manufacturing process?

- Special steel has various applications in the oil and gas manufacturing process. It is commonly used in the construction of pipelines, offshore platforms, and equipment for drilling and extraction. Special steel's high strength and corrosion resistance properties make it ideal for handling the demanding conditions encountered in oil and gas operations. Additionally, it is used in the production of valves, pumps, and other critical components that require durability and reliability to ensure efficient and safe processes in the industry.

- Q: How is special steel used in the production of automotive parts?

- Special steel is used in the production of automotive parts due to its exceptional strength, durability, and resistance to corrosion. It is commonly used in components like engine parts, suspension systems, and gears to ensure optimal performance, safety, and longevity of vehicles.

- Q: What is the role of boron in special steel alloys?

- Boron plays a crucial role in special steel alloys by enhancing their hardenability, which is the ability of the steel to be hardened through heat treatment. It acts as a grain refiner, allowing for a finer and more uniform microstructure in the steel, resulting in improved mechanical properties such as increased strength and toughness. Additionally, boron helps to prevent the formation of harmful oxides during steel production, leading to improved overall quality and performance of the alloy.

- Q: What are the different methods for improving the fatigue strength of special steel?

- There are various ways to enhance the fatigue strength of special steel: 1. Heat treatment is a commonly used approach, involving processes like annealing, quenching, and tempering. These treatments refine the steel's microstructure, reduce impurities, and boost fatigue resistance. 2. Surface treatments, such as shot peening and nitriding, can also enhance fatigue strength. Shot peening bombards the steel surface with small metal particles, inducing compression stress that prevents crack formation and propagation. Nitriding diffuses nitrogen into the surface layer, creating a hard and wear-resistant nitride layer that improves fatigue resistance. 3. Alloying special steel with specific elements, like chromium, molybdenum, or vanadium, can significantly improve fatigue strength. These elements form carbides or nitrides, acting as barriers against crack propagation. 4. Applying protective surface coatings, like electroplating, hot-dip galvanizing, or physical vapor deposition (PVD), can enhance fatigue strength. These coatings act as barriers against environmental factors that may cause corrosion or surface damage, ultimately extending the steel's fatigue life. 5. Grain refinement can be achieved through processes like severe plastic deformation or equal channel angular pressing (ECAP). By refining the grain size, the steel's fatigue strength can be improved, as fine-grained steels have higher resistance to crack initiation and propagation. 6. Residual stress management plays a crucial role in enhancing fatigue strength. Techniques like stress relieving or shot peening can reduce tensile residual stresses, which are detrimental to fatigue resistance. It's important to consider specific requirements, the type of special steel, and the intended application when selecting the most suitable method for improving fatigue strength.

- Q: How does special steel perform in cryogenic applications?

- Special steel is renowned for its exceptional performance in cryogenic applications, characterized by extremely low temperatures that fall below -150 degrees Celsius (-238 degrees Fahrenheit). Unlike regular steel, which tends to become brittle and weaker in such conditions, special steel, also referred to as cryogenic steel or low-temperature steel, is specifically engineered to withstand these extreme cold temperatures. One of the key advantages of special steel lies in its ability to maintain its mechanical properties even at cryogenic temperatures. It retains its strength, toughness, and ductility, enabling it to endure the stresses and strains imposed on it in cryogenic environments. As a result, special steel finds application in various fields, including aerospace, energy, and healthcare, where it is used in cryogenic storage tanks, pipelines, and equipment. Another significant feature of special steel is its excellent resistance to brittle fracture at low temperatures. This is of utmost importance since brittle fractures occur when materials become excessively brittle and fail under stress. The distinct composition and processing methods employed in special steel help prevent such fractures, ensuring the integrity and safety of components within cryogenic systems. Furthermore, special steel possesses a low coefficient of thermal expansion, meaning it undergoes minimal dimensional changes when exposed to temperature fluctuations. This characteristic proves highly advantageous in cryogenic applications as it preserves the stability and reliability of equipment and structures. Additionally, special steel exhibits commendable corrosion resistance, which is vital in cryogenic environments where the presence of moisture and certain chemicals can accelerate corrosion processes. By resisting corrosion, special steel enhances the longevity and durability of components, thereby reducing maintenance and replacement costs. In conclusion, special steel is the preferred choice for cryogenic applications due to its ability to maintain mechanical properties, resist brittle fracture, display low thermal expansion, and exhibit corrosion resistance. These properties render it a dependable and efficient material for use in cryogenic systems, providing the necessary strength and durability even under extremely low-temperature conditions.

- Q: How is special steel used in the textile supply chain?

- Special steel is used in various applications within the textile supply chain, primarily in the manufacturing of textile machinery and equipment. It is utilized for components such as shafts, bearings, gears, and springs, which are crucial for the smooth functioning and efficiency of textile machinery. Special steel's high strength, durability, and resistance to wear and corrosion make it an ideal material for these demanding applications. Additionally, special steel may also be employed in the production of textile cutting tools and needles, further enhancing the quality and precision of textile products.

- Q: How is special steel used in the manufacturing of tools and dies?

- Special steel is widely used in the manufacturing of tools and dies due to its exceptional properties that make it suitable for these applications. Special steel, also known as tool steel, is specifically designed to have high hardness, wear resistance, toughness, and heat resistance. In the manufacturing of tools, such as drills, saws, hammers, and chisels, special steel is used to ensure durability and long tool life. The high hardness of special steel allows these tools to withstand the rigors of cutting, drilling, and shaping without easily dulling or deforming. Additionally, the wear resistance of special steel ensures that these tools can maintain their sharp cutting edges for an extended period, reducing the need for frequent sharpening or replacement. Moreover, in the production of dies used in various manufacturing processes, special steel plays a crucial role. Dies are used to shape materials into specific forms or sizes, such as in forging, stamping, or extrusion processes. The high toughness of special steel allows dies to withstand the high pressure and impact forces involved in these processes without cracking or fracturing. Additionally, the heat resistance of special steel ensures that dies can withstand the elevated temperatures generated during these operations without losing their shape or hardness. Special steel also offers excellent machinability, allowing it to be easily shaped and formed into complex tool and die designs. This property is significant in manufacturing, as it enables the production of intricate and precise tools and dies, leading to improved product quality and efficiency. Overall, special steel is an essential material in the manufacturing of tools and dies due to its exceptional hardness, wear resistance, toughness, heat resistance, and machinability. These properties ensure the durability, long tool life, and high performance of tools and dies, contributing to the overall efficiency and quality of various manufacturing processes.

- Q: How does special steel play a role in the defense sector?

- Special steel plays a crucial role in the defense sector due to its unique properties and characteristics that make it highly suitable for various applications. Firstly, special steel offers exceptional strength and durability, making it ideal for manufacturing military vehicles, armored personnel carriers, and tanks. These vehicles require materials that can withstand high impacts, resist deformation, and provide protection against enemy attacks. Additionally, special steel is used in the production of military aircraft and naval vessels. Its high strength-to-weight ratio allows for the construction of lightweight yet robust structures, enabling aircraft to carry heavy payloads and naval vessels to navigate through harsh conditions. Moreover, special steel's corrosion resistance properties make it suitable for marine environments, ensuring the longevity and reliability of naval assets. Furthermore, special steel is utilized in the production of weapons and ammunition. Its hardness and toughness attributes make it suitable for manufacturing firearm barrels, armor-piercing projectiles, and other critical components. Special steel's ability to withstand extreme pressures, temperatures, and impact forces ensures the accuracy, reliability, and effectiveness of military weaponry. Moreover, special steel is also employed in the defense sector for the production of communication and surveillance equipment. Its electromagnetic properties allow for the fabrication of radar systems, antennas, and electronic enclosures that are essential for military operations. Special steel's resistance to electromagnetic interference ensures the integrity and security of communication systems, enhancing the overall efficiency and effectiveness of defense operations. In summary, special steel plays a vital role in the defense sector by providing the necessary strength, durability, corrosion resistance, and electromagnetic properties required for various applications. Its utilization in military vehicles, aircraft, naval vessels, weapons, and communication equipment enhances the overall capabilities, effectiveness, and safety of defense forces, ensuring national security.

Send your message to us

Round Bar and Deformed Bar Grade 460A_460B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords