460B Steel Round Bars for BS/EN Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

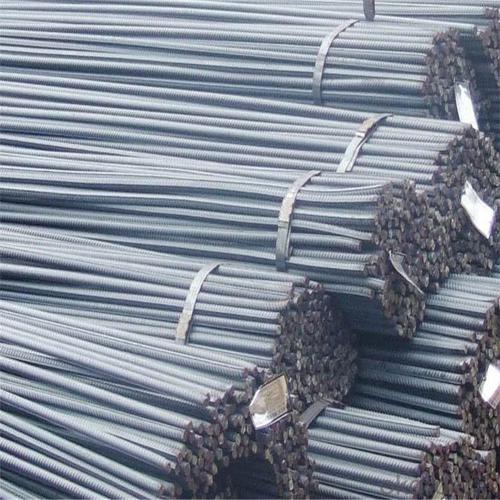

460B Steel Round Bars

Description of 460B Steel Round Bars

1, Diameter: 5.5mm-10mm 460B Steel Round Bars

10m- 40mm 460B Steel Round Bars

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of 460B Steel Round Bars

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of 460B Steel Round Bars

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the applications of special steel in the food processing industry?

- Special steel is widely used in the food processing industry due to its unique properties. It is utilized for manufacturing various equipment and components that require high strength, corrosion resistance, and hygiene standards. Some applications include the production of food processing machinery, cutting tools, knives, blades, and containers. Special steel ensures durability, cleanliness, and safety, making it an indispensable material in the food processing industry.

- Q: How does special steel contribute to the construction machinery industry?

- Special steel plays a crucial role in the construction machinery industry by providing high-strength and durable components. These components are essential for heavy-duty applications in construction machinery, such as excavators, bulldozers, cranes, and loaders. One of the key contributions of special steel to the construction machinery industry is its ability to withstand extreme stress and load-bearing requirements. Construction machinery often operates under severe conditions, including heavy loads, vibrations, and impacts. Special steel, with its excellent mechanical properties, can resist these conditions and maintain its structural integrity, ensuring the safety and reliability of the equipment. Moreover, special steel is often used in critical components of construction machinery, such as booms, buckets, tracks, and gears. These components are subjected to intense wear and tear due to constant use in harsh environments. Special steel, engineered with enhanced hardness and wear resistance, helps extend the lifespan of these components, reducing maintenance costs and downtime. Additionally, special steel provides superior corrosion resistance, which is vital for construction machinery used in humid or corrosive environments. By preventing rust and decay, special steel helps maintain the equipment's performance and longevity, ultimately increasing productivity and efficiency in construction projects. Furthermore, special steel enables the construction machinery industry to achieve innovative designs and advanced functionalities. Its versatility allows for the creation of complex shapes and precise tolerances, which are essential for optimizing the performance and efficiency of machinery. Special steel also enables the incorporation of advanced technologies, such as sensors and automation, enhancing the accuracy and productivity of construction equipment. In summary, special steel contributes significantly to the construction machinery industry through its ability to withstand extreme conditions, provide superior wear resistance and corrosion protection, and enable innovative designs. By utilizing special steel in the manufacturing process, construction machinery manufacturers can ensure the durability, safety, and efficiency of their equipment, ultimately benefiting the construction industry as a whole.

- Q: Is special steel magnetic?

- Certainly, special steel possesses the ability to exhibit magnetism. The magnetism displayed by steel relies upon its composition and the inclusion of specific elements, like iron, nickel, and cobalt. Special steels that incorporate these magnetic elements are capable of showcasing magnetic properties. Nonetheless, it is important to note that not all forms of steel possess magnetism. For instance, certain stainless steels possess elevated levels of non-magnetic elements, such as chromium, which diminish their magnetic properties. Consequently, whether a particular kind of special steel possesses magnetism or not hinges upon its composition.

- Q: What are the applications of special steel in the marine sector?

- Special steel is extensively used in the marine sector due to its unique properties. It is used in various applications such as shipbuilding, offshore platforms, and marine equipment manufacturing. Special steel provides excellent corrosion resistance, high strength, and durability, making it ideal for marine environments that are highly corrosive and subject to extreme conditions. It is used for constructing hulls, propeller shafts, pipelines, and various components of ships and offshore structures. Additionally, special steel's ability to withstand impact and fatigue makes it suitable for marine applications where safety and reliability are crucial.

- Q: What are the specific requirements for special steel used in the textile machinery industry?

- The special steel requirements for the textile machinery industry can differ based on the specific application and machinery involved. Nevertheless, there are several common requirements in this industry. Firstly, corrosion resistance is crucial as textile machinery is frequently exposed to moisture, chemicals, and other corrosive substances. Therefore, the special steel used must possess excellent corrosion resistance properties to ensure durability and longevity. Secondly, high strength is necessary since textile machinery operates under high loads and stresses. Consequently, the special steel employed must have strong characteristics to withstand these forces and prevent deformation or failure. Furthermore, wear resistance is important as textile machinery involves constant contact between different components, leading to wear and tear. Thus, the special steel utilized should exhibit good wear resistance properties to minimize friction and extend the machinery's lifespan. Additionally, heat resistance is vital as textile machinery often operates at high temperatures due to friction generated during the manufacturing process. Consequently, the special steel used should possess exceptional heat resistance to prevent deformation or loss of mechanical properties under high temperature conditions. Moreover, machinability is necessary for the special steel used in the textile machinery industry. This allows for the production of complex components with precise dimensions, ensuring smooth and efficient machinery operation. Lastly, cost-effectiveness is crucial while meeting all the aforementioned requirements. Manufacturers strive to balance performance and cost to maintain competitiveness in the market without compromising on quality. It is important to note that these requirements can vary depending on the specific application within the textile machinery industry. As a result, manufacturers and engineers must carefully evaluate their machinery's requirements and choose the appropriate special steel accordingly.

- Q: How does special steel contribute to the renewable energy aftermarket industry?

- Enhancing the efficiency, durability, and cost-effectiveness of renewable energy systems, special steel plays a critical role in the aftermarket industry. Wind turbine components are one of the primary beneficiaries of special steel in this industry. To withstand harsh environmental conditions and generate electricity efficiently, wind turbines require materials that are both high-strength and corrosion-resistant. Special steel alloys, such as high-strength low-alloy (HSLA) steel and stainless steel, offer exceptional mechanical properties, fatigue resistance, and corrosion resistance, making them an ideal choice for critical wind turbine components like rotor blades, tower structures, and more. By incorporating special steel into wind turbine manufacturing, the aftermarket industry can enjoy several advantages. Turbine lifespan is extended, maintenance costs are reduced, and energy output is improved. The strength and durability of special steel also allow for the construction of taller and larger wind turbine towers, enabling the installation of turbines in areas with lower wind speeds. This expansion of suitable locations maximizes the potential for energy production, making wind energy a more viable and widespread renewable energy source. Additionally, special steel contributes to the aftermarket industry through its application in solar power systems. Solar panels require sturdy mounting structures to handle the weight of the panels, withstand wind and snow loads, and ensure optimal sun exposure. Special steel, with its high strength-to-weight ratio and corrosion resistance, is commonly used in these mounting structures, providing long-lasting and reliable support for solar panels. Moreover, special steel finds applications in other renewable energy systems such as hydroelectric power plants and geothermal systems. These industries benefit from the corrosion resistance and ability to withstand extreme temperatures offered by special steel, ensuring the longevity and efficiency of the equipment. Overall, special steel plays a significant role in driving the growth and adoption of renewable energy sources worldwide. By enabling the production of reliable, durable, and efficient renewable energy systems, special steel contributes to the success of the aftermarket industry. Whether in wind turbines, solar panels, or other renewable energy technologies, special steel enhances performance and longevity, ultimately advancing the use of renewable energy sources on a global scale.

- Q: What are the applications of special steel in the automotive manufacturing process?

- Special steel is widely used in the automotive manufacturing process for various applications. It is commonly used for making engine components like crankshafts, camshafts, and connecting rods due to its high strength and resistance to wear and heat. Special steel is also used for manufacturing suspension systems, steering components, and chassis parts, as it offers excellent mechanical properties and durability. Additionally, special steel is utilized in the production of safety features such as seatbelt components and airbag systems, ensuring the highest level of protection for occupants. Overall, special steel plays a crucial role in enhancing the performance, reliability, and safety of vehicles in the automotive industry.

- Q: How does special steel contribute to the manufacturing of aerospace components?

- Special steel plays a crucial role in the manufacturing of aerospace components by offering superior strength, durability, and heat resistance properties. This type of steel, specifically designed for aerospace applications, ensures the structural integrity and reliability of crucial aircraft parts, such as landing gears, turbine blades, and engine components. Additionally, special steel's unique composition allows for reduced weight, thus enhancing fuel efficiency and improving overall aircraft performance. By providing these essential characteristics, special steel contributes significantly to the safety, efficiency, and advancement of aerospace manufacturing.

- Q: Can special steel be used in the production of surgical instruments?

- Yes, special steel can be used in the production of surgical instruments. Special steel alloys, such as stainless steel, are commonly used due to their desirable properties like corrosion resistance, strength, and their ability to be easily sterilized. These characteristics make special steel an ideal material for surgical instruments that require high precision and durability.

- Q: Can special steel be used in the plastic manufacturing industry?

- Yes, special steel can be used in the plastic manufacturing industry. Special steel alloys, such as tool steels, can be employed in the production of molds and dies used for shaping and forming plastic materials. These high-strength steels are essential for withstanding the high temperatures and pressures involved in plastic injection molding and other manufacturing processes. Special steel's durability and resistance to wear make it an ideal choice for enhancing the longevity and performance of plastic manufacturing equipment.

Send your message to us

460B Steel Round Bars for BS/EN Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords