Roofing Insulation Disc - Aluminum Foil Coated Bubble Insulation Type 7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bubble Insulation Benefits:

Reflects 96% of radiant heat

Non-toxic / Non-carcinogenic

Does not require protective clothing or respirators to install

Durable and lightweight

Does not compress, collapse or disintegrate

Vapor and radon retarder

Easy to cut and install

Permanent and maintenance-free

Does not provide a growth medium or nutritive value for fungus, insects, or rodents

Does not support the growth of mold or mildew

Not affected by moisture or humidity

Lowers heating and cooling costs year round

Bubble Foil Application:

Metal & Steel Buildings

Homes

Roof Underlayments

Cathedral Ceilings

Crawl Spaces

Hot Water Heaters

Basement Walls

Floors

Garage Doors

Concrete slabs

Driveway snow melts

Pole barns

Post frame buildings

Poultry barns

Animal kennels

Temperature sensitive storage areas

Air Bubble Foil Insulation Tech Data:

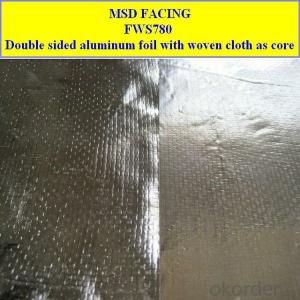

Material Structure: AL/Bubble/AL | ||

Bubble Size:D10mm*H 4mm(10*2.5/10*4/10*6/20*7/25*10)choose the bubble size | ||

Bubble Weight:0.13kg/m2 ( can be customized ) | ||

Roll Width:1.2m (lenth can be customized) | ||

PROPERTIES | TEST DATA | UNIT |

Thickness | 3.5-4 | mm |

Weight | 250 | g/m2 |

Emissivity | 0.03-0.04 | COEF |

Thermal conductivity | 0.034 | w/m0 |

Apparent Density | 85 | kg/m3 |

Reflectivity | 95-96 | % |

Water Vapour Transmission | 0.013 | g/m2kpa |

Corrosion | doesn't generate | |

Tensile Strength(MD) | 16.98 | Mpa |

Tensile Strength(TD) | 16.5 | Mpa |

- Q: what effect does changing the pitch of a roof have on the insulation properties and durability of a roof?

- I'd have to agree with mj, your insulation in your ceiling is the major factor for heating and cooling , spec R-38 but if your going for gov. kick backs I think it's R-41 (17" of blown in fiberglass insulation). Roof pitch standard is 1' raise to 4' run, (really easy to re-roof & inexpencive). Advantages of a steep roof (less apt to have leakage problems with a worn roof, you get a few more yrs). When you have to replace that roof, price goes up for steepage.

- Q: p/t deck on a commercial rubber roof do we need closed cell insulation under deck to protect rubber?

- First I would put some walk pads down, I don't know if you can purchase them at your local home center. There should be a specialty store that sells vinyl siding they should have them they are about two foot by two foot rubber squares that have dots on them they look like suction cups. Place these pads dots down so that water will drain under the pads, then place a piece of 2" x 8" about 16" long of p/t blocking on top, this will help transfer the load of the deck on the rubber walk pad on the rubber roof. Place the pads and blocks where ever you place your 4" x 4" s You are now ready to start framing the deck. GOOD LUCK!!!

- Q: do i leave air gap in attic roof for insulation?

- The best way to set up an attic is to put a vapor barrier under the rafters (before nailing on the gyproc), then put the insulation (fibreglas batts) between the rafters to full depth (10 or 12 inches). Soffit vents are installed under the eaves at the sides of the roof, and gable vents are placed near the peak of the roof at the ends. This allows for airflow resulting from convection, particularly important in the summer months to remove heat buildup in the attic. If the insulation is adequate, it will not only isolate this heat buildup from the inside of the house in summer, but will prevent heat loss to the attic in winter. (The airflow in winter will be minimal, but will remove any moisture/condensation that might collect otherwise.)

- Q: does insulation, with a high R value, in the attic prolong the life of the shingles on the roof.

- No. Ventilation prolongs the life of a roof. Ventilation also reduces the air conditioning bill by a huge amount. If you use a lot of AC, also add an automatic attic fan. As for insulation, the idea is to have a good R factor, relative to where you live, directly above the highest living space ceiling in the house

- Q: what's the best insulation for ceilling for house with semi flat roof?

- The pitch of your roof has nothing to do with the kind of insulation you should use. I recommend a fiberglass insulation that is at least 6 inches thick, the more you put in the better.

- Q: What is the aim of insulation in walls and in roofs?

- Neither, it is to not let heat through.

- Q: I know when you inhale the insulation from the roof irritates the throat but what can you do to clear it from your throat after inhaling it?

- it's not your throat you should be worried about. it's your lungs. wear a respirator....or at the very least, a dust mask. you only live once so make it last.

- Q: I have read in some articles about roofing that it is recommended to use attic roof insulation in ones roofing. Is this true?

- here in the uk not only is it necessary ..its the law ..under building control up to 250mm 10" of fibreglass is needed ...it keeps house warm in winter and cool in summer

- Q: What can i do to add more insulation in a addition in my house?The Roof is flat on this addition (no attic room for insulation there).Looks like it's only 4 or 5 inches thick, starts from the inside with 1/2 inch drywall and the rest is plywood, and then that black sheeting on the outside.IS THERE ANYTHING MORE THAT CAN BE DONE TO ADD MORE INSULATION ON THE OUTSIDE?, (i can't do anything on the inside since the ceiling is already low) SINCE IN THIS ROOM IS VERY HOT, even touching the celing feels warm, PLEASE HELP!

- You could build a pitched roof on top of the flat roof.

- Q: I have a vented metal roof. WV winters

- Check into heat tape tied to pipe, with insulation wrapped around that. turns on when freezing temperatures. insulation by itself, will not stop it from freezing if left for long periods without water moving through it. .

Send your message to us

Roofing Insulation Disc - Aluminum Foil Coated Bubble Insulation Type 7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords