Rogue Stainless Steel Bars - Selling Manufacturers Stainless Steel China 304 316 316L

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Best selling manufacturers stainless steel china 304 316 316l square pipe

All the materials are up to standard of GB, ROHS, SVCH.

We also accept the order of random length and other material's stainless steel pipes.

Our pipes are attractive and durable, that's the reason why we are the preferred supplier of Furniture, Handles, Sanitary Ware, and Medical Devices.

Product Details of Stainless Steel Pipe:

| Name | stainless tube |

| Standard | ASTM A554,A249,A269,A270,A312 |

| Material Grade | 201,202,304,316,316L,430 |

| Main Material | 201: Ni 0.8%~1%,202: Ni 3.5%~4.5%,304: Ni 8%,Cr 18%,316: Ni 10%,Cr 18%,316L: Ni 10%~14%,430: Cr 16%~18% |

| Outer Diameter | 8mm-76.2mm |

| Thickness | 0.5mm-1.5mm |

| Length | 6m or according to customers's request |

| Tolerance | a)Outer Diameter :+/- 0.1mm b) Thickness:+/- 0.02mm c) Length:+/- 5mm |

| Surface | 180G,240G,320G Hairline,400G,600G Mirror finish |

| Application | handrail,railing,staircase,weldmesh screen,door,window,balcony,fence,bench,furniture,ect. |

| Test | Squash test,extended test,water pressure teat,crystal rot test,heat treatment,NDT |

Know more about trade...

Payment term: 1. 30% T/T in advance, and the balance against B/L copy

2. 100% irrevocable LC at sight.

Shipment date: Within 15-20 days after advance payment or receipt of LC

Trade term: 1. FOB Shanghai port, China.

2. CIF Discharging port

Guarantee& Service: Mill Test Certificate is supplied with shipment, and Third Part Inspection is acceptable.

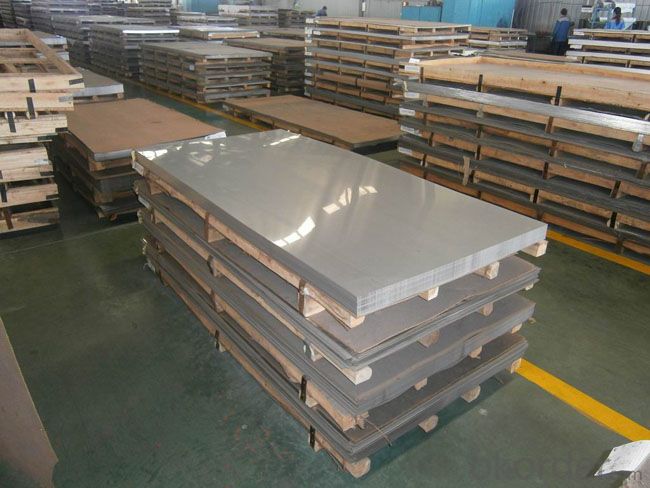

Packing: standard export packing (plastic package to prevent water or plywood case to strengthen package)

- Q:What are the different types of stainless steel bar shapes for structural applications?

- There are several different types of stainless steel bar shapes that are commonly used for structural applications. Some of the most common shapes include round bars, square bars, flat bars, and hexagonal bars. These shapes offer varying strengths and versatility, allowing for different applications and structural designs.

- Q:Are stainless steel bars suitable for the production of springs?

- Yes, stainless steel bars are suitable for the production of springs. Stainless steel has excellent corrosion resistance, high strength, and good elasticity, making it an ideal material for producing springs. It can withstand high temperatures and maintain its shape and performance over time, making it a reliable choice for various applications that require durable and efficient springs.

- Q:Can stainless steel bars be used in chemical storage tanks?

- Indeed, chemical storage tanks can utilize stainless steel bars. With its exceptional resistance to corrosion and chemical reactions, stainless steel proves to be an optimal material for storing a diverse array of chemicals. Its remarkable strength and durability guarantee the tank's structural integrity. By employing stainless steel bars for reinforcement, the tank structure receives supplementary support. Moreover, stainless steel boasts ease of cleaning and maintenance, a vital aspect in preventing contamination within chemical storage tanks. In summary, stainless steel bars serve as a dependable and fitting selection for chemical storage tanks due to their corrosion resistance, strength, and durability.

- Q:Can stainless steel bars be used in food packaging applications?

- Yes, stainless steel bars can be used in food packaging applications. Stainless steel is a durable and corrosion-resistant material that is safe for use in contact with food. It offers excellent hygiene, strength, and temperature resistance, making it suitable for various food packaging needs, including storage containers, utensils, and equipment.

- Q:What are the applications of stainless steel bars?

- Stainless steel bars have a wide range of applications in various industries due to their exceptional properties and versatility. Some of the common applications of stainless steel bars include: 1. Construction and Architecture: Stainless steel bars are widely used in the construction industry for structural support, reinforcement, and in the fabrication of architectural components such as handrails, balustrades, and decorative elements. Their corrosion resistance and aesthetic appeal make them a popular choice for modern architectural designs. 2. Manufacturing and Engineering: Stainless steel bars are utilized in manufacturing processes such as machining, forging, and welding to produce components for various machinery and equipment. Their high strength, durability, and resistance to wear and tear make them suitable for manufacturing applications that require reliability and longevity. 3. Food and Beverage Industry: Stainless steel bars are widely used in the food and beverage industry due to their hygienic properties and resistance to corrosion. They are commonly used in the production of food processing equipment, storage tanks, kitchen utensils, and brewing equipment, ensuring a safe and clean environment for food and beverage production. 4. Medical and Pharmaceutical: Stainless steel bars find extensive use in medical and pharmaceutical applications due to their biocompatibility, corrosion resistance, and ease of sterilization. They are used in the fabrication of surgical instruments, medical implants, and laboratory equipment, ensuring high-quality and safe healthcare practices. 5. Automotive and Transportation: Stainless steel bars are used in the automotive and transportation industry for various applications, including the production of exhaust systems, chassis components, drive shafts, and fasteners. Their strength, heat resistance, and corrosion resistance make them an ideal choice for parts that require durability and performance in demanding conditions. 6. Energy and Power Generation: Stainless steel bars are utilized in the energy and power generation sector for applications such as the production of turbine blades, heat exchangers, and valves. Their resistance to high temperatures, pressure, and corrosion ensures the efficiency and longevity of power generation systems. 7. Marine and Offshore Industry: Stainless steel bars are extensively used in the marine and offshore industry due to their excellent resistance to saltwater corrosion. They are used in the construction of ships, offshore platforms, and marine equipment, providing durability and longevity in harsh marine environments. In summary, stainless steel bars find applications in a wide range of industries due to their exceptional properties such as corrosion resistance, strength, durability, and versatility. From construction and manufacturing to medical and automotive sectors, stainless steel bars play a crucial role in various applications, ensuring reliability, safety, and performance.

- Q:How do stainless steel bars resist heat?

- Stainless steel bars resist heat due to their high chromium content, which forms a protective oxide layer on the surface. This oxide layer acts as a barrier, preventing the underlying metal from reacting with oxygen and other elements in the environment, thus maintaining the bar's structural integrity even at high temperatures.

- Q:How are stainless steel bars priced?

- Stainless steel bars are priced based on several factors. Firstly, the grade or quality of the stainless steel plays a significant role in determining the price. Higher-grade stainless steel bars, such as those made from 316 or 304 stainless steel, are generally more expensive due to their superior corrosion resistance and durability. The dimensions and size of the stainless steel bars also impact the pricing. Longer and thicker bars tend to be more costly as they require more raw material and manufacturing processes. Additionally, specialized shapes or customized cuts may incur additional costs. Market demand and supply dynamics also influence the pricing of stainless steel bars. Fluctuations in raw material costs, availability, and overall demand for stainless steel products can lead to price variations. Economic conditions, global trade policies, and geopolitical factors can also impact stainless steel bar prices. Furthermore, the price of stainless steel bars is influenced by the supplier or distributor. Different suppliers may have varying pricing strategies, overhead costs, and profit margins, which can result in different prices for the same product. Lastly, it is important to consider any additional costs such as transportation, packaging, or taxes that may be included in the final pricing of stainless steel bars. Overall, stainless steel bar prices are determined by the grade, size, market conditions, supplier factors, and additional costs associated with the product.

- Q:Are stainless steel bars resistant to abrasion and wear?

- Yes, stainless steel bars are highly resistant to abrasion and wear due to their inherent strength and durability. The composition of stainless steel, combined with its smooth surface finish, provides excellent resistance to friction, making it ideal for applications where abrasion and wear are major concerns.

- Q:Do stainless steel bars require any post-weld treatments?

- Post-weld treatments are often necessary for stainless steel bars to guarantee their durability and resistance against corrosion. Although stainless steel is known for its inherent resistance to corrosion, the welding process can change its properties and create susceptible areas. Sensitization occurs when welding heat leads to the formation of chromium carbide precipitates, depleting the steel's chromium content and making it prone to corrosion. To prevent sensitization and restore the stainless steel's corrosion resistance, different post-weld treatments can be applied. One widely used treatment is known as solution annealing, which entails heating the stainless steel to a specific temperature and rapidly cooling it. This procedure aids in dissolving the chromium carbide precipitates and redistributing the chromium evenly throughout the material. Another post-weld treatment is passivation, which involves applying a chemical solution to the surface of the stainless steel. Passivation eliminates any iron contaminants and forms a protective oxide layer on the metal, enhancing its resistance to corrosion. The specific post-weld treatments necessary for stainless steel bars may vary depending on the grade and intended application of the material. Consulting welding experts or following the manufacturer's recommendations is crucial in determining the appropriate post-weld treatments for stainless steel bars to ensure their optimal performance and longevity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rogue Stainless Steel Bars - Selling Manufacturers Stainless Steel China 304 316 316L

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords