201 Stainless Steel Round Bar Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product name: 201 stainless steel round bar

Name | 201 stainless steel round bar |

Standard | AISI, ASTM, JIS,GB,EN,DIN |

Grade | 201/304/316/304L/316L |

Technology | Hot Drawn and Cold Drawn |

Form | Round/Square/Hexagonal Bar |

Diameter | 0.3 mm – 100mm |

| Length | Customized |

The sizes or thickness of stainless steel Bar can be customized. Our customer service staffs are available 7/24. | |

Chemical Composition (%)< stainless steel bar >

Type | C | Si | Mn | P | S | Ni | Cr | Mo |

201 | ≤0.15 | ≤0.75 | 5.5-7.5 | ≤0.06 | ≤0.03 | 3.5-5.5 | 13.5-15.0 | |

202 | ≤0.15 | ≤1.0 | 7.5-10.0 | ≤0.06 | ≤0.03 | 4.0-6.0 | 17.0-19.0 | |

304 | ≤0.08 | ≤1.00 | ≤2 | ≤0.035 | ≤0.030 | 10.0~14.0 | 18.0-20.0 | |

304L | ≤0.03 | ≤1.00 | ≤2 | ≤0.035 | ≤0.030 | 8.0~11.0 | 18.0-20.0 | |

316 | ≤0.08 | ≤1.00 | ≤2 | ≤0.035 | ≤0.030 | 10.0~14.0 | 16.0~18.5 | 2.0-3.0 |

316L | ≤0.03 | ≤0.75 | ≤2 | ≤0.045 | ≤0.030 | 10.0~14.0 | 16.0~18.5 | 2.0-3.0 |

Advantages of 201 stainless steel polished round bar

A : Elegance Surface and Diversity Usage

B : Corrosion Resistance and Longer Srevice Life

C :Heat Resistance

D: High Strength

F :High Strength of Oxidation Resistance

G: High Plasticity

H: Easy Surface Treatment

I : Hygiene and High Degree of Finish

J: Excellent Welding Performance

Our experience in developing and pioneering specialized stainless steel fabrications for our customers has made us solidly proficient at prototyping and design.

Because we specialize in multiple industries and reap manufacturing expertise,

we will be able to make your custom parts in the most cost-efficient manner.

Additionally, we have launched our own product line.

We are always open to new challenges and we are constantly working to increase our stainless steel fabricating skills and thereby reduce your costs as well as ours.

Stainless steel manufacturing is an art and a science;

it's a science because we relentlessly seek efficiency

It's an art because we expect and respect your particular needs.

Call us!

We want for your inquiry.

Technological Process of 201 stainless steel polished round bar

Quality Speaks Volumes

Boro has developed and produced premium stainless steel fabrications for over five hundred manufacturing, military, and general industrial companies.

We've run thousands of jobs and thousands of part designs.

We have outstanding deliverability and are ISO BV SGS registered .

So you know you're getting a quality product.

Our experience with reducing costs for our customers through long-run jobs is proven and reliable.

With many long term customers, our stainless steel fabrication services

are low cost and high quality in this present world marketplace.

Boro pursues improvement in every department. Roughly one tenth of company revenue is spent on new technology, renovations, improvements, & strategic market preparation.

Our entire business model (prospect to job close) has been completely value streamed and most of our workflow is strictly managed & controlled.

We maintain records and backups of all pertinent job data.

Company Information

China National Building Materials Group Corporation (CNBM) was established in 1984 with approval of the State Council, and then became a Central Enterprise under direct supervision of State-owned Assets Supervision and Administration Commission of the State Council in 2003. It is in charge of the administrative affairs in China building materials industry. By the end of 2013, CNBM’s total assets exceeded RMB 360 billion, with over 130,000 employees, and 20 companies under direct management with 100% share control or majority control, among which 6 were listed companies, including 2 oversea listed. On July 7th, 2014, CNBM with revenue USD 41028 million, was ranked 267th on the ”World Top 500 Enterprises” by Fortune Magazine.

PACK & DELIVERY

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

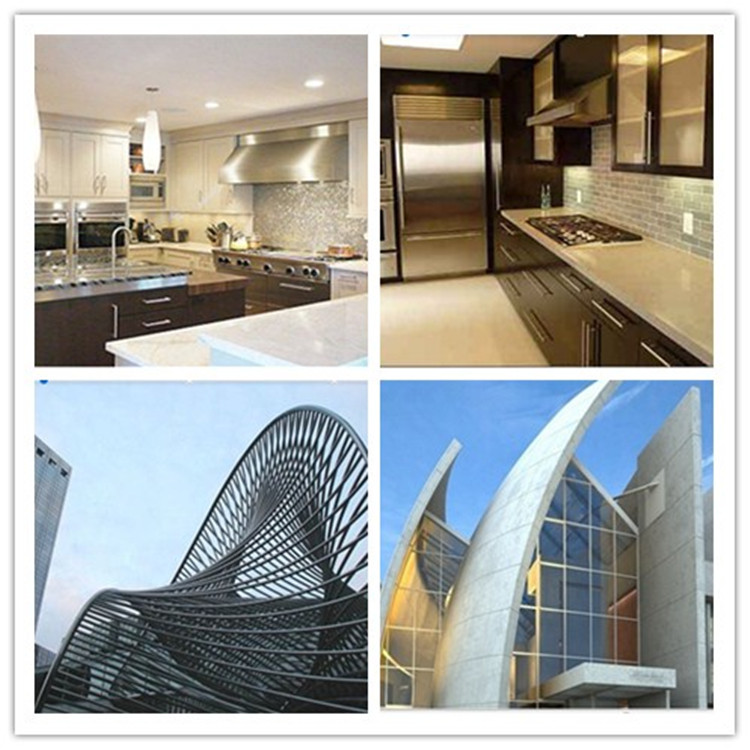

Application

F A Q

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

- Q: How do stainless steel bars resist nitric acid?

- Stainless steel bars resist nitric acid due to the presence of chromium in their composition. Chromium forms a protective oxide layer on the surface of the stainless steel, known as the passive layer. This passive layer acts as a barrier, preventing the nitric acid from coming into direct contact with the underlying metal. The chromium oxide layer is highly stable and self-healing, meaning that even if it gets damaged, it quickly reforms, ensuring continued protection against nitric acid corrosion. Additionally, stainless steel bars often contain other alloying elements such as molybdenum, which further enhance their resistance to nitric acid. Overall, the combination of chromium and other alloying elements create a strong and corrosion-resistant material that can withstand the corrosive effects of nitric acid.

- Q: Can stainless steel bars be used in high-pressure applications?

- Indeed, high-pressure applications can make use of stainless steel bars. Renowned for its remarkable corrosion resistance and impressive strength, stainless steel proves to be an apt choice in enduring environments with intense pressure. Moreover, various industries including oil and gas, chemical processing, and aerospace frequently employ stainless steel bars, exposing them to exceedingly demanding pressure circumstances. To ensure utmost performance and safety, it is vital to select the appropriate grade of stainless steel that aligns with the specific demands of the application.

- Q: Are stainless steel bars resistant to chemicals?

- Yes, stainless steel bars are highly resistant to chemicals. Stainless steel contains a high percentage of chromium, which forms a protective layer on the surface of the metal. This layer, known as the passive film, prevents the steel from reacting with chemicals and provides excellent resistance to corrosion. Stainless steel bars can withstand exposure to a wide range of chemicals, including acids, alkalis, solvents, and even some aggressive substances. This makes them suitable for use in various industries, such as chemical processing, pharmaceuticals, and food processing, where they may come into contact with different types of chemicals. Overall, stainless steel bars offer exceptional resistance to chemical attack, ensuring their durability and longevity in harsh environments.

- Q: Do stainless steel bars have good resistance to oxidation?

- Yes, stainless steel bars have good resistance to oxidation.

- Q: How do you store stainless steel bars to prevent corrosion?

- To prevent corrosion and maintain the quality of stainless steel bars, proper storage is crucial. Here are some key steps to follow: 1. Keep the bars in a clean and dry environment: Moisture and dirt can accelerate the corrosion process. Store the stainless steel bars in a clean and dry area, away from any potential sources of moisture or humidity. Avoid storing them directly on the floor or near open windows or doors. 2. Use protective covers or wraps: To protect the stainless steel bars from dust, dirt, and potential chemical reactions, consider covering them with protective wraps or covers. This will act as a barrier and minimize the risk of corrosion. 3. Avoid contact with other metals: Stainless steel can undergo galvanic corrosion when it comes into contact with certain other metals. Prevent this by storing stainless steel bars separately from any other metals, especially those with different compositions or higher corrosion potentials. 4. Minimize exposure to chemicals: Stainless steel is generally resistant to many chemicals, but certain substances can cause corrosion. Keep the bars away from direct contact with chemicals such as acids, alkalis, and chlorides. If stored near chemicals, ensure proper ventilation and implement effective containment measures. 5. Maintain proper ventilation: Adequate airflow can prevent the buildup of moisture and humidity, reducing the chances of corrosion. If your storage area lacks natural ventilation, consider using fans or dehumidifiers to maintain a dry environment. 6. Regularly inspect and clean the storage area: Periodically inspect the storage area for any signs of leaks, moisture, or potential sources of corrosion. Keep the area clean, removing any debris or dust that may accumulate over time. By following these precautions and best practices, you can effectively store stainless steel bars to prevent corrosion and ensure their long-term durability and quality.

- Q: Are stainless steel bars resistant to creep rupture?

- Generally speaking, stainless steel bars are resistant to creep rupture. Creep rupture occurs when a material gradually deforms and fails under constant load and high temperatures for an extended period of time. Stainless steel is renowned for its strength and exceptional resistance to heat, corrosion, and oxidation. These characteristics make it highly resistant to creep rupture. The addition of alloying elements like chromium and nickel in stainless steel provides increased stability and strength at elevated temperatures, effectively preventing or minimizing the deformation that could result in rupture. Moreover, stainless steel undergoes a process known as work hardening, which enhances its strength and resistance to deformation. This work hardening effect further improves the resistance of stainless steel bars to creep rupture. It is important to note, however, that the resistance to creep rupture of stainless steel bars can vary depending on the specific alloy used and the operating conditions they are exposed to. Stainless steels with higher alloy content, such as the austenitic grades (e.g., 304, 316), generally exhibit greater resistance to creep rupture compared to stainless steels with lower alloy content (e.g., 410, 430). Additionally, operating temperatures and applied loads can also affect the resistance to creep rupture. In conclusion, stainless steel bars are known for their good resistance to creep rupture and are commonly employed in applications that require high strength and reliability at elevated temperatures.

- Q: Can stainless steel bars be electroplated?

- Stainless steel bars are indeed capable of being electroplated. Electroplating is a method whereby a thin layer of metal is deposited onto the surface of another metal object by means of an electrolytic cell. Given that stainless steel is a conductive material, it is well-suited for electroplating. Nevertheless, there are specific factors to consider when electroplating stainless steel bars. Stainless steel possesses a passive layer comprised of chromium oxide on its surface, which imparts corrosion resistance. Prior to electroplating, this passive layer must be eliminated or altered, as it can impede the adhesion of the plated metal. Moreover, stainless steel contains nickel, which can permeate into the plated metal and cause discoloration or other complications. Therefore, proper surface preparation, such as sandblasting or etching, is imperative to ensure optimal adhesion and a successful electroplating process on stainless steel bars.

- Q: Can stainless steel bars be used in heat exchanger applications?

- Yes, stainless steel bars can be used in heat exchanger applications. Stainless steel has excellent corrosion resistance and heat transfer properties, making it a suitable choice for heat exchangers. Additionally, stainless steel bars can withstand high temperatures and pressure, making them reliable for such applications.

- Q: Do stainless steel bars have good wear resistance?

- Yes, stainless steel bars have excellent wear resistance due to their unique composition and properties. The addition of chromium in stainless steel enhances its corrosion resistance and provides a protective layer, which also contributes to its wear resistance.

- Q: What are stainless steel bars used for?

- Stainless steel bars possess durability, strength, and corrosion resistance properties that find extensive use in diverse industries. The construction industry frequently utilizes stainless steel bars to reinforce concrete structures like bridges, buildings, and highways, ensuring the longevity and structural integrity of these projects. In the manufacturing sector, stainless steel bars play a crucial role in producing machinery and equipment. These bars are machined, formed, or welded to create components that require high strength, heat resistance, chemical resistance, and wear resistance. Industries such as automotive, aerospace, and oil and gas heavily rely on stainless steel bars for manufacturing parts like shafts, valves, fasteners, and fittings. The food and beverage industry extensively utilizes stainless steel bars due to their non-reactive nature. This makes stainless steel an ideal material for food processing equipment, including conveyor systems, mixers, tanks, and storage containers. It ensures the safety and hygiene of food products by preventing contamination and facilitating easy cleaning. Furthermore, the marine industry heavily relies on stainless steel bars due to their excellent resistance to saltwater corrosion. These bars are commonly used in boat fittings, propeller shafts, and other components exposed to harsh marine environments. Additionally, stainless steel bars find application in architectural projects such as handrails, balustrades, and decorative elements. The aesthetic appeal, durability, and low maintenance requirements of stainless steel make it a popular choice for enhancing the appearance and functionality of buildings and public spaces. In conclusion, stainless steel bars serve diverse purposes across various industries. Their versatility, strength, and corrosion resistance make them indispensable in the construction, manufacturing, food processing, marine, and architectural sectors.

Send your message to us

201 Stainless Steel Round Bar Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords