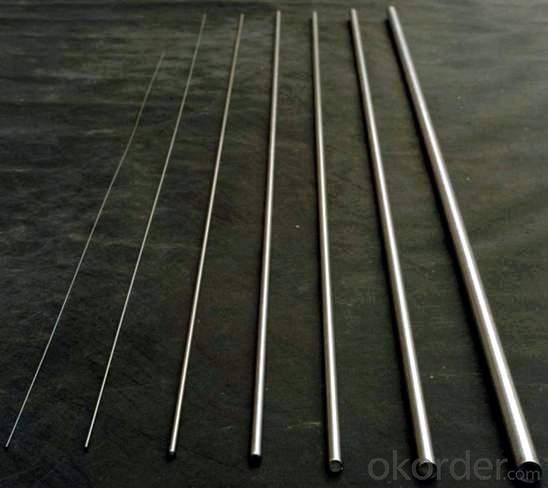

Stainless Steel Black Bar

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 4000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details of Stainless Steel Black Bar:

Hot Rolled

DIA 10mmto 130mm

FORGE

DIA 130mm to 300mm

GB1220,ASTM A 484/484M, EN 10060/ DIN 1013

DIA 3mm to 60mm

INCH 1/8" to 2 1/4"

INCH 1/8" to 2 1/4"

Tolerance: GB1220, ISASTM A276/A 484M, EN 10278, DIN 671

Item | SS304,316L,420C,440C Stainless steel ball |

Category | Stainless Steel Ball |

Material | AISI 420 430 440 SS304 316L |

Size | 0.5mm--25.4mm, 1/4",3/16",5/32",1/8",7/32",5/16",7/8",1" |

Grade | G100-G3000 |

Hardness ( HRC) | HRC58-65 |

Application | Bicycle, bearing, pulley, slide, handcraft, shelf, luggage, hardware, grinding media |

Standard | GB/T-308-2002, GB/T1148-93 |

Matched Standard | DIN, JIS, ASME |

Certification | ISO |

Packing | Oily packing in pouch packing,plastic/tin box packing 1, 25kg/carton with steel pallet packing 2,25kg/carton without steel pallet packing 3,10kg/box then in wooden case packing 4,250kg/ steel drum packing or according to customers' requirement |

Place of original | Shandong province, China |

Delivery | Within 30 days or confirmed while placing order |

Advantages of Stainless Steel Black Bar:

1. All products are made of high-quality imported raw materials.

2. Our products are certified by ISO9001:2008 authentication quality systems.

3. We are nominated as the AAA enterprise by Jiangsu government.

4. Quickest and most efficient Response to Your Enquiry.

Specifications of Stainless Steel Black Bar:

1.Features: Low density, high specific strength, high corrosion resistance, good thermal stability and plasticity.

2.It is widely applied for petroleum, chemical, mechanical and electrical, hardware, etc.

3.Quality assurance: All of the products are detected by ultrasound making sure that no defects inside the products. Besides, chemical composition, mechanical properties and high-powered organization are also strictly controlled, ensuring our clients get the best products.

Packing details of Stainless Steel Black Bar:

Products are well packed and clear labeled according to the regulations and customer's requests.

Intact packages are able to avoid any damage which might otherwise be caused during storage or transportation.

After service of Stainless Steel Black Bar:

1. One-year follow:

We’ll follow up and concern each order within a year. If there’re any problems of our order or product, you can contact us.

2. Quick reply:

If you find any quality problem after receiving the goods, you can contact us, we will manage and reply you in 48 hours.

- Q: Can stainless steel bars be used in food processing?

- Food processing can indeed make use of stainless steel bars. The food and beverage industry highly favors stainless steel for its many desirable qualities. Its resistance to corrosion allows it to endure exposure to moisture, acids, and other corrosive substances typically found in food processing environments. Moreover, stainless steel possesses a smooth and non-porous surface, facilitating easy cleaning and maintenance of proper hygiene standards. Furthermore, stainless steel is a robust and durable material capable of withstanding high temperatures and heavy loads, thus making it appropriate for a range of food processing applications including conveyor systems, storage tanks, and equipment frames. In summary, stainless steel bars are a dependable and secure option for use in food processing.

- Q: What are the different types of stainless steel bar shapes?

- There are several different types of stainless steel bar shapes available in the market. Some common ones include round bar, square bar, hexagonal bar, and flat bar. 1. Round Bar: This is the most common type of stainless steel bar shape. It is cylindrical in shape and can be used for various applications, such as shafts, bolts, and fasteners. 2. Square Bar: As the name suggests, this type of stainless steel bar has a square cross-section. It is often used in construction and manufacturing industries for making frames, supports, and braces. 3. Hexagonal Bar: Hexagonal bars have six sides and are often used when a stronger and more rigid structure is required. They are commonly used in applications such as machinery, automotive, and aerospace industries. 4. Flat Bar: Flat bars have a rectangular cross-section with smooth and flat surfaces. They are widely used for architectural purposes, such as window frames, handrails, and decorative elements. Flat bars are also commonly used in construction, manufacturing, and general fabrication. These different types of stainless steel bar shapes offer versatility and can be selected based on the specific requirements of a project. Each shape has its own unique properties and advantages, making them suitable for various applications in different industries.

- Q: What are the typical mechanical properties of stainless steel bars?

- Stainless steel bars have a unique combination of mechanical properties that make them highly desirable in various applications. Some of the typical mechanical properties of stainless steel bars include: 1. Tensile Strength: Stainless steel bars exhibit excellent tensile strength, which refers to the maximum amount of stress a material can withstand before breaking or deforming. Stainless steel bars can have a tensile strength ranging from 500 to 2,000 megapascals (MPa), depending on the specific alloy and heat treatment. 2. Yield Strength: Yield strength is the amount of stress a material can withstand before it begins to deform permanently. Stainless steel bars generally have a yield strength ranging from 200 to 1,500 MPa, making them resistant to bending or undergoing plastic deformation under load. 3. Hardness: Stainless steel bars are known for their high hardness, which is the ability of a material to resist indentation or scratching. The hardness of stainless steel bars can vary depending on the alloy and heat treatment, ranging from 150 to 600 Brinell hardness (HB). This hardness ensures the bars are durable and can withstand wear and tear in demanding environments. 4. Ductility: Ductility refers to the ability of a material to undergo plastic deformation without breaking. Stainless steel bars generally exhibit good ductility, allowing them to be shaped or bent without fracturing. The elongation at break, which measures the percentage of deformation a material can undergo before breaking, can range from 10% to 50% in stainless steel bars. 5. Corrosion Resistance: One of the most significant advantages of stainless steel bars is their exceptional resistance to corrosion. They contain a minimum of 10.5% chromium, which forms a thin, protective oxide layer on the surface that prevents oxidation and corrosion. This corrosion resistance makes stainless steel bars suitable for applications in harsh environments, such as marine or chemical industries. 6. Thermal Conductivity: Stainless steel bars possess moderate thermal conductivity, allowing them to transfer heat efficiently. The thermal conductivity can range from 15 to 30 watts per meter-kelvin (W/m·K), depending on the specific alloy. This property makes stainless steel bars useful in applications where heat dissipation is essential. Overall, stainless steel bars offer a combination of strength, hardness, ductility, corrosion resistance, and thermal conductivity, making them widely used in industries such as construction, automotive, aerospace, and food processing.

- Q: Can stainless steel bars be coated?

- Indeed, it is possible to coat stainless steel bars. Coating stainless steel bars is widely practiced to elevate their aesthetic appeal, offer protection against corrosion, or enhance their mechanical attributes. Numerous coating alternatives are accessible for stainless steel bars, such as electroplating, powder coating, PVD (Physical Vapor Deposition) coating, and specialized coatings. These coatings can be administered to stainless steel bars to alter their color, amplify their resistance to rust and corrosion, or bolster their durability. The selection of coating is contingent upon the particular application and the intended outcome for the stainless steel bars.

- Q: Can stainless steel bars be etched?

- Yes, stainless steel bars can be etched. Etching is a process that involves using an acid or chemical solution to remove material from the surface of the stainless steel, creating a design or pattern. This technique is commonly used for decorative purposes or to apply identification markings on stainless steel bars.

- Q: Can stainless steel bars be used in cryogenic storage tanks?

- Cryogenic storage tanks can make use of stainless steel bars, as they possess excellent resistance to low temperatures. Stainless steel is widely recognized for its ability to withstand extreme cold temperatures, making it a common choice for cryogenic applications. Its structural integrity remains intact and it does not deteriorate when exposed to the required cold conditions for cryogenic storage. Due to their high strength, corrosion resistance, and ability to maintain mechanical properties at low temperatures, stainless steel bars are frequently utilized in the construction of cryogenic storage tanks. Moreover, stainless steel's low thermal conductivity effectively minimizes heat transfer between the stored contents and the external environment. Therefore, stainless steel bars are a reliable and suitable option for cryogenic storage tanks.

- Q: Can stainless steel bars be used in corrosive environments?

- Yes, stainless steel bars can be used in corrosive environments. Stainless steel is known for its excellent corrosion resistance properties, making it suitable for use in environments where other materials may corrode or deteriorate. The chromium content in stainless steel forms a protective oxide layer on the surface, which acts as a barrier against corrosion and rusting. Additionally, stainless steel bars can be further alloyed with elements such as molybdenum, nickel, or titanium to enhance their resistance to specific types of corrosive environments, such as those containing acids, salts, or chlorides. Overall, stainless steel bars are widely used in various industries, including chemical processing, marine, food processing, and pharmaceutical, where they are exposed to corrosive substances or environments.

- Q: What is the typical weight of stainless steel bars?

- The typical weight of stainless steel bars can vary depending on their dimensions and grade. However, as a general guideline, the weight of stainless steel bars is calculated by multiplying the cross-sectional area (in square inches) by the density of stainless steel (around 0.29 pounds per cubic inch). This means that the weight can range from a few pounds for smaller bars to several hundred pounds for larger ones. It is always advised to consult the specifications or consult with a supplier to determine the exact weight of a specific stainless steel bar.

- Q: How do you determine the size and length of a stainless steel bar?

- To determine the size and length of a stainless steel bar, you can follow a few simple steps. 1. Measure the diameter: Use a caliper or a ruler to measure the diameter of the stainless steel bar. Ensure that you measure at the widest point of the bar, as stainless steel bars can have varying dimensions along their length. 2. Measure the length: Use a measuring tape or a ruler to determine the length of the stainless steel bar. Make sure to measure from one end to the other, excluding any threaded or chamfered portions if applicable. 3. Check the specifications: If you have access to the manufacturer's specifications or product information, you can refer to those to determine the size and length of the stainless steel bar. These specifications often provide precise details about the dimensions and tolerances of the bar. 4. Consult a professional or reference guide: If you are unsure about how to accurately measure or determine the size and length of a stainless steel bar, it is always advisable to consult a professional or refer to a reliable reference guide. They can provide guidance and assistance in accurately determining the dimensions of the bar. Remember, stainless steel bars can come in various shapes and forms, such as round bars, square bars, or hexagonal bars. The measuring technique may slightly differ based on the specific shape of the bar, but the above steps should generally help you determine the size and length of a stainless steel bar.

- Q: Can stainless steel bars be used in aerospace applications?

- Indeed, aerospace applications can make use of stainless steel bars. Stainless steel, renowned for its versatility and durability, boasts remarkable resistance to corrosion and a commendable strength-to-weight ratio, rendering it a fitting choice for a myriad of aerospace components. Aircraft structures, engine parts, landing gear, and fasteners are among the numerous applications commonly employing stainless steel. Particularly, stainless steel bars frequently find utility in scenarios necessitating outstanding strength and durability, exemplified by their presence in wing spars, fuselage frames, and engine mounts. Moreover, stainless steel's ability to withstand high temperatures and extreme weather conditions further solidifies its status as a dependable option for aerospace applications.

Send your message to us

Stainless Steel Black Bar

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 4000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords