Cold Drawn Stainless Steel Round Bar for Wholesales

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Chemical Composition

| Standard | Material/ Grade | C | Si | Mn | Cr | V | P | S |

| ≤ | ||||||||

| DIN 17221 | 60SiCr7 | 0.57-0.65 | 1.50-1.80 | 0.70-1.00 | 0.20-0.40 | 0.030 | 0.030 | |

| 55Cr3 | 0.52-059 | ≤0.40 | 0.70-1.00 | 0.70-1.00 | 0.025 | 0.025 | ||

| 60Cr3 | 0.56-0.64 | 0.17-0.37 | 0.70-1.00 | 0.70-1.00 | 0.025 | 0.025 | ||

| 50CrV4 | 0.47-0.55 | 0.15-0.40 | 0.70-1.00 | 0.70-1.10 | 0.10-0.20 | 0.030 | 0.030 | |

| JIS G4801 | SUP6 | 0.55-0.65 | 1.50-1.80 | 0.70-1.00 | --- | 0.035 | 0.035 | |

| SUP7 | 0.55-0.65 | 1.80-2.20 | 0.70-1.00 | --- | 0.035 | 0.035 | ||

| SUP9 | 0.52-0.60 | 0.15-0.35 | 0.65-0.95 | 0.65-0.95 | 0.030 | 0.030 | ||

| SUP9A | 0.56-0.64 | 0.15-0.35 | 0.70-1.00 | 0.70-1.00 | 0.030 | 0.030 | ||

| SUP10 | 0.47-0.55 | 0.15-0.35 | 0.65-0.95 | 0.80-1.10 | 0.15-0.25 | 0.030 | 0.030 | |

| SAE J1268 | 9260/H | 0.55-0.65 | 0.70-1.20 | 0.65-1.10 | ≤0.2 | 0.040 | 0.030 | |

| 5155 | 0.50-0.60 | 0.15-0.35 | 0.65-1.10 | 0.60-1.00 | 0.040 | 0.030 | ||

| 5160/H | 0.55-0.65 | 0.15-0.35 | 0.65-1.10 | 0.60-1.00 | 0.040 | 0.030 | ||

| 6150 | 0.47-0.54 | 0.15-0.35 | 0.60-1.00 | 0.75-1.20 | ≤ 0.15 | 0.040 | 0.030 | |

Product Description

Product Overviews:

Product Name | Typical Grades | Diameter(mm) | Standard adopted |

Carbon Steel | 20 (1020/S20C/C22) |

Ø16-Ø300 |

GB/SAE/JIS/DIN |

40 (1040/S40C/C40) | |||

45 (1045/S45C/C45) | |||

Bearing Steel | GCr9 (51100/SUJ1) |

Ø12-Ø250 | |

GCr15 (52100/SUJ2/100Gr6) | |||

GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) |

Ø12-Ø250 | |

40Cr (5140/SCr440/41Cr4) | |||

42CrMo(4140/SCM440/42CrMo4) | |||

Gear Steel | 20CrNiMo |

Ø16-Ø600 | |

20CrMn(5115/SMnC420/20MnCr5) | |||

20CrNiMo(8620/SNCM220/20CrMiMo2) |

Detailed Information:

1, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet - hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

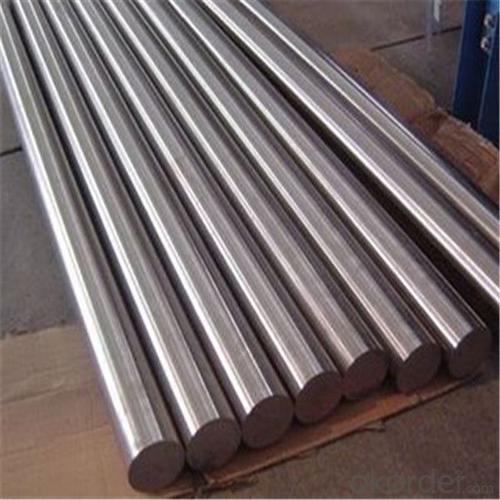

The picture of the products

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Application:

Carbon Steel | Mold bottom Plastic mold Construction machinery parts Automobile parts Security grills Screens Construction |

Bearing Steel | Aerospace Navigation Nuclear energy Chemical industry Electronic information Petrochemical Instrument and meter Transportation |

Cr-Mo Steel | Mechanism & Fasteners gear Stressed components for vehicles Engines and machines Parts of larger cross-section |

Gear Steel | All kinds of gears Statically and dynamically stressed component for vehicles Engines and machine Larger cross-section parts Crankshafts |

Packaging & Shipping

Packaging & Delivery:

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

After-sale service:

CNBM provides the services and support you need for every step of our cooperation.

We’re the business partners you can trust; you can relax and get on with doing business.

For any problem, please kindly contact us at any your convenient time,

we’ll reply you in our first priority within 24 hours

Our Services

Advantages

· Industry experience over 20 years.

· Shipment of goods -More than 70 countries worldwide.

· The most convenient transport and prompt delivery.

· Competitive price with best service.

· High technical production line with top quality products.

· High reputation based on best quality products.

With our experienced, enthusiastic and dynamic staffs, we assure to bring you the products with best quality, reasonable prices and good after-sales services under the motto: Friends First, Business After.

Communication, Experience, Expertise and Best efforts are our Promises to you.

- Q: Can stainless steel bars be used in outdoor environments?

- Yes, stainless steel bars can be used in outdoor environments. Stainless steel is known for its excellent corrosion resistance, which makes it highly suitable for outdoor applications. It can withstand exposure to various elements such as rain, humidity, UV radiation, and even saltwater. Stainless steel bars are commonly used in outdoor structures like railings, fences, and grills, as well as in marine and coastal environments. Their durability, strength, and resistance to rust and corrosion make stainless steel bars a reliable choice for outdoor use.

- Q: Can stainless steel bars be used in the chemical aftermarket?

- Yes, stainless steel bars can be used in the chemical aftermarket. Stainless steel is highly resistant to corrosion and can withstand the harsh chemical environments commonly found in the chemical industry. It is often used for the construction of tanks, pipes, and other equipment that come into contact with chemicals. Stainless steel bars offer excellent strength and durability, making them suitable for various applications in the chemical aftermarket.

- Q: Are stainless steel bars suitable for outdoor sculptures and artworks?

- Yes, stainless steel bars are highly suitable for outdoor sculptures and artworks. Stainless steel is a durable and corrosion-resistant material that can withstand the harsh outdoor elements, making it an excellent choice for creating long-lasting and low-maintenance sculptures and artworks. It is resistant to rust, staining, and fading, which ensures that the artwork remains visually appealing for an extended period of time. The strength and structural integrity of stainless steel bars also allow for the creation of intricate and large-scale sculptures. Additionally, stainless steel can be easily shaped, welded, and polished, providing artists with the flexibility to bring their creative visions to life. Overall, the properties of stainless steel make it an ideal material for outdoor sculptures and artworks, ensuring their beauty and longevity in various weather conditions.

- Q: Are stainless steel bars suitable for architectural balustrades?

- Indeed, architectural balustrades benefit greatly from the use of stainless steel bars. As a material, stainless steel boasts high durability and resistance to corrosion, rendering it perfect for outdoor installations like balustrades. Moreover, stainless steel demands minimal maintenance, ensuring little effort is needed to keep it in pristine condition over the years. Furthermore, its sleek and contemporary look enhances the overall visual appeal of buildings and structures. Stainless steel bars can be crafted in a multitude of sizes and designs, catering to diverse architectural styles and needs. Ultimately, stainless steel bars offer a robust and reliable solution for architectural balustrades, guaranteeing strength and security.

- Q: What is the typical diameter range of stainless steel round bars?

- The typical diameter range of stainless steel round bars can vary depending on the specific application and industry requirements. However, in general, stainless steel round bars are available in a wide range of diameters. Common diameter sizes for stainless steel round bars can range from as small as 1/8 inch (3.175 mm) to as large as 20 inches (508 mm) or even more. The exact diameter range will depend on factors such as the grade of stainless steel, the manufacturing process, and the intended use of the round bar. It is essential to consult the relevant industry standards, specifications, or suppliers to determine the specific diameter range required for a particular application.

- Q: Can stainless steel bars be used in the food and beverage industry?

- Certainly, the food and beverage industry can utilize stainless steel bars. This industry frequently selects stainless steel for its outstanding ability to resist corrosion, its durability, and its hygienic properties. Stainless steel bars serve various purposes, including the formation of structures, the creation of shelving units, the manufacturing of food processing equipment, and the construction of countertops and work surfaces. The exceptional resistance to rust and staining make stainless steel bars an ideal choice for contact with food and beverages, as they do not taint or modify the taste or quality of the products. Furthermore, stainless steel is simple to clean and maintain, which is vital in an industry where cleanliness and sanitation reign supreme. In general, stainless steel bars are widely embraced and employed in the food and beverage industry due to their dependability, safety, and suitability for handling and processing food.

- Q: What is the average cost of stainless steel bars?

- The average cost of stainless steel bars can vary depending on various factors such as size, grade, quantity, and market conditions. It is advisable to check with suppliers or conduct research to get the most accurate and up-to-date pricing information.

- Q: What is the difference between centerless ground and peeled stainless steel bars?

- The main difference between centerless ground and peeled stainless steel bars lies in the manufacturing process. Centerless ground bars are produced by grinding the surface of the stainless steel bar to achieve precise dimensions and a smooth finish. This process removes any imperfections and ensures tight tolerances. On the other hand, peeled stainless steel bars are created by removing the outer layer of the stainless steel bar through a peeling process. This results in a smooth, clean surface while retaining the original size of the bar. Overall, centerless ground bars are more suitable for applications that require precise dimensions, while peeled bars are preferred when a smooth surface finish is the main requirement.

- Q: Are stainless steel bars suitable for outdoor furniture?

- Yes, stainless steel bars are highly suitable for outdoor furniture. Stainless steel is known for its exceptional durability and resistance to corrosion, making it an excellent choice for outdoor applications. It can withstand exposure to various weather conditions, including rain, sun, and humidity, without rusting or deteriorating. Additionally, stainless steel has a sleek and modern appearance that complements many outdoor design styles. It is also easy to clean and maintain, making it a practical choice for outdoor furniture that will last for many years.

- Q: Can stainless steel bars be used in chemical plant applications?

- Yes, stainless steel bars can be used in chemical plant applications. Stainless steel is highly resistant to corrosion and chemical reactions, making it a suitable material for handling various chemicals in a chemical plant environment. Its durability, strength, and ability to withstand high temperatures also make it a preferred choice for many applications within the chemical industry.

Send your message to us

Cold Drawn Stainless Steel Round Bar for Wholesales

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords