Rockwool Sandwich Panels South Africa with Logo Cmax Prepared House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

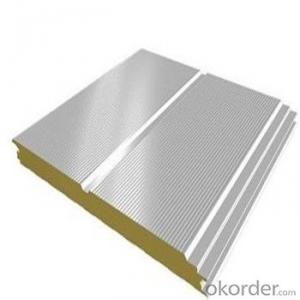

Rockwool sandwich panel

1.Material EPS/XPS/PU /PC wall panel

2.Composite sandwich panel

3.ISO9001:CE

4.Sandwich panel suppli

Rockwool sandwich panel

Henan B.R.D New Materials Co., Ltd devotes itself to producing green materials,Rockwool sandwich panel,

keeping Innovation, and be on the pursuit of quality first as well as integrity others.For the future,

we would still act up to our corporate vision to have the environmen-friendly materials to be more widely used.

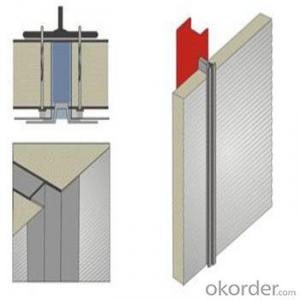

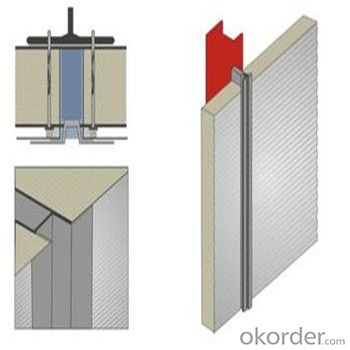

Rockwool sandwich panel and its manufacturing process is one the most advanced inventions, which in the factory automation equipment, rock wool and steel into a whole, thus changing the way of the rock wool plate before the compound required site , under the premise that meet the requirements of the building thermal insulation, sound insulation, fire protection, to achieve a high quality, efficient, reliable, safe target. The products in Europe through a wide range of applications, sophisticated.

Purposes: the company of rock wool sandwich panel roof and wall are two types of widely used in a fireproof, sound insulation, thermal insulation requirements of industrial and civil roof, external walls and internal partitions, especially fire demanding projects.

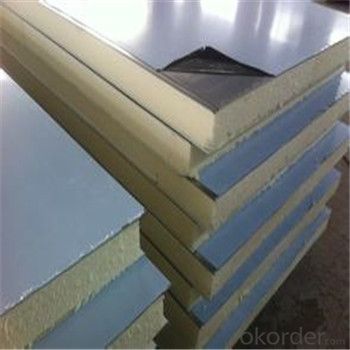

The up & down surface of this rockwool panel is Galvanized & Pre-painted steel sheets, core material is 5 components rockwool glue, it is formed by heating, foaming & laminating. Rockwool is the best material for temperature keeping and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

1.Features:

1. Heat and sound insulation. Temperature suitable for PU ranges from -200 centigrade to 150 centigrade.

2. Good chemical resistance, waterproof, anti-corrosion, insect-free etc.

3. Advanced Tech: Automatic rolling machines make the whole process of manufacture effective.

4. Energy conservation, environmental protection, economical, heat insulting, good structure, easy-doing construction

5. Light weight enough to reduce building expense.

6. Time can be saved on a building project due to the simple installation

2.Specification:

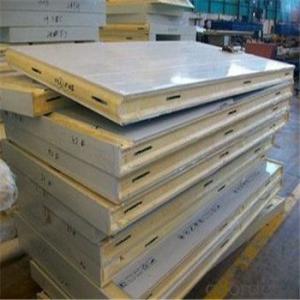

Steel Thickness | 0.4~0.8mm |

Panel thickness | 50/75/100/125/150 mm |

Effective width | (1) 950/mm ---for roof (2) 950/1000mm---for wall or ceiling |

Length | According to customer's request, less than 11.8m |

Materials | Inner is Rockwool, two sides is Color steel tile |

Structure | three layers: (1)upper layer is steel sheet, (2)the inner layer is Rockwool sandwich, (3)the bottom layer is also steel sheet |

Rockwool density | 30-50(kg/m³),etc |

color | blue, white grey, or other colors . |

Parts | Steel line for easy connect one by one Film covering in order to protect the steel of panels |

lifetime | 15~20 years |

Character | Light in weight, heat insulation, fireproof and water proof, environmental |

Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums ,etc |

Packing | Packed by shipping Container or according to your demands |

FAQ

A, Could be changed the size of the panel?

Yes, we design the size according to your requirement.

B, What is the color of the panel?

All the colors in "RAUL"

- Q: I have a temporary pavement, the roof for the Caigang sandwich panels, north and west for the pure glass wall, south of four large area of plastic windows, east brick wall, an area of 150 square feet, 5 meters high. Summer sun good time when the house hot, temperature 35 degrees or more. Ask how the decoration, so that the temperature can come down, the cheaper the better the cost. (The ceiling has no effect, the role of large or small, there is no other way) Thank you, high score waiting. More

- If it is added foam cement insulation board, just add a bubble device, the principle of insulation is the air bubble to reduce heat conduction. Foam plastic cement insulation pedal brother Xi Jiadian tripod end plate is added EPS polystyrene foam, insulation principle is polystyrene foam to reduce heat conduction.

- Q: Reinforced concrete and metal sandwich board how much difference

- Light steel plant roof static load can be divided into the following . the roof for the single-layer + cotton insulation, 0.20KN / M. the roof for the double board + insulation cotton, 0.25KN / M. the roof for the foam sandwich panels, if 50 thick, 0.3KN / M2 specific calculation, assuming purlin per meter specific gravity of . the distance is 1.. then converted to 7 / 1.5 = 5 kg or so insulation cotton generally in 1 kg, pull the sub-component 2 kg, single Floor panel 0.5 thick -0.5 * 7.85 = 4 kg then the roof of a single board + insulation cotton, constant load of 5 +1 +2 +4 = 12 kg per square meter of the actual design time to enlarge the point, take a 0.. Otherwise your trial is also very sad.

- Q: Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. Sandwich panels are made up of two outer layers or skins with a lightweight core material in between, providing excellent strength and insulation properties. These panels are versatile and can be used for various applications, including building facades, partitions, and interior walls. In automotive showrooms, sandwich panels can be used for constructing walls, ceilings, and even floors. They offer several benefits that make them ideal for this environment. Firstly, sandwich panels provide excellent insulation, which helps maintain a comfortable temperature inside the showroom, regardless of the weather outside. This is crucial for creating a pleasant environment for both customers and staff. Additionally, sandwich panels are lightweight and easy to install, allowing for quick and efficient construction. This is beneficial for automotive showrooms, as they often have tight deadlines and need to be operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, allowing for flexibility in creating unique and attractive showroom layouts. Sandwich panels also offer good noise reduction properties, ensuring a quieter environment within the showroom. This is important for providing a comfortable atmosphere for customers and allowing them to focus on the vehicles on display. Furthermore, sandwich panels are durable and require minimal maintenance. They are resistant to corrosion, moisture, and fire, ensuring a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for branding and aesthetic preferences to be incorporated into the showroom design. Overall, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They provide a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- I have a veteran to sell, because I just bought a new Taiwan, the price of ..

- Q: How the exterior of the house is made of rock wool color steel sandwich panels

- Construction, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, Erecting outside the scaffolding materials expected ribs of the late section of the dwarf light dog chupu count, template support frame, shelf safety operation technology. Zibu type construction fastener, by the two holes in the diameter of the child is significantly different, the female fastener riveting, two fasteners on the lower cover are steel stamping parts, cover, under the cover with ribs , The upper and lower cover of the middle part of the arc inward convex, the arc-shaped convex surface and the upper and lower cover on both sides of the same cylindrical surface, the child, the female fastener nut on the same size. The fastener is used to build construction scaffolding, building fence, planting greenhouses, etc., can be connected to different diameter pipe, can be rotated angle, wide range of applications, and the fastener weight, bending strength and good steel, , Easy to use.

- Q: What are the different types and uses of clean color steel plates?

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed time when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the amount of rain on the big leak, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask!

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- . different fire rating: Yanmian sandwich panels for the A-level, EPS for the B3-class, polyurethane B1 level. . different insulation properties: the three polyurethane sandwich panels the best. . waterproof performance is different: the three polyurethane and EPS better than rock wool. . the density of different: rock wool bulk density is generally 120KG / cubic meter, EPS is generally . polyurethane is generally 40. In short, the overall performance of polyurethane sandwich panels for the best, is the best choice for steel structure, Have a number.

- Q: Can the foam sandwich be used as a cleaning plate?

- According to the "construction of fasteners steel scaffolding safety technical specifications" JGJ

- Q: 50mm thickness of color steel foam sandwich board how much money a flat

- The heat dissipation part of the rosewood boiler is made up of pure aluminum radiator and axial fan

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- Expandable polystyrene foam board (referred to as polystyrene board, the EPS board). Polystyrene Biscuit Powder Kuba Kawakun Fung Mo foam products are processed intermediate products, with less investment, fast turnover, low energy consumption, occupation of production personnel less, the production of high profit products. At the same time the number of devices less simple operation, strong production flexibility, product quality has a reliable guarantee, and thus the project construction risk is small. EPS board is made of polystyrene (EPS) beads made by foam molding. Polystyrene is invented in the 1950s, polystyrene foam products is a new type of advanced insulation, noise insulation materials. It is light in quality, non-toxic and tasteless, without any pollution. Use is very wide, mainly used for refrigerators, trains, ships, limousines, mobile homes, housing insulation insulation. Instrumentation, porcelain, glass products, home appliances and other packaging. In the construction industry it is an alternative to moisture-proof powder, perlite, asbestos and other insulation materials, is a very wide range of new products, so far there is no one product to replace the market prospects are very broad.

Send your message to us

Rockwool Sandwich Panels South Africa with Logo Cmax Prepared House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords