RingLock scaffolding Accessories for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

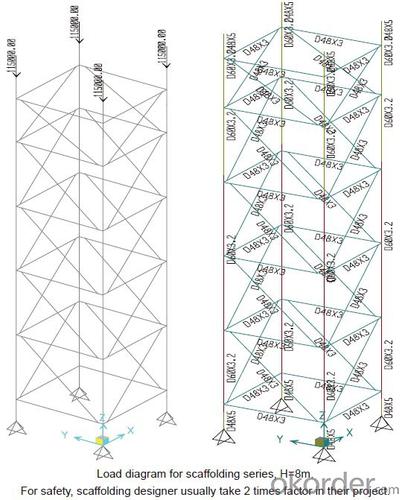

Ring-lock Scaffolding

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: What are the considerations when designing steel formwork for swimming pools?

- When designing steel formwork for swimming pools, there are several important considerations to take into account. These considerations include the structural integrity and strength of the formwork, the accuracy and precision of the formwork's dimensions, the ease of assembly and disassembly, and the ability to withstand the corrosive effects of water and pool chemicals. Firstly, the structural integrity and strength of the steel formwork are crucial. The formwork must be able to support the weight and pressure exerted by the concrete during pouring and curing. It should be designed to resist any potential deformation or buckling that could compromise the pool structure. The thickness and reinforcement of the steel must be carefully calculated to ensure it meets the required load-bearing capacity. The accuracy and precision of the formwork's dimensions are also important considerations. The formwork should be designed to provide precise and consistent dimensions to ensure the pool's shape and size are accurately maintained. This is particularly critical for swimming pools, where any deviation from the intended design may result in uneven water levels or compromised aesthetic appeal. Ease of assembly and disassembly is another consideration. The formwork should be designed for easy installation and removal to facilitate efficient construction processes. The components should be designed to fit together securely and allow for quick adjustments or modifications if necessary. This can help reduce construction time and labor costs. Furthermore, the corrosive effects of water and pool chemicals need to be taken into account. Steel formwork should be treated or coated with materials that can withstand the exposure to water and chemicals commonly found in swimming pools. This helps prevent rust and deterioration, ensuring the longevity and durability of the formwork. In conclusion, designing steel formwork for swimming pools requires careful consideration of structural integrity, dimensional accuracy, ease of assembly, and resistance to corrosion. By addressing these considerations, the formwork can provide a solid foundation for the construction of a high-quality and long-lasting swimming pool.

- Q: Is steel formwork resistant to fire?

- Steel formwork is generally resistant to fire. Its high melting point and lack of easy ignition or contribution to fire spread make it suitable for construction projects that require fire-resistant materials. Steel formwork is designed and manufactured to withstand high temperatures without deformation or structural failure. This not only ensures its own fire resistance but also provides better fire protection for the concrete being poured into it, as concrete has inherent fire-resistant properties. However, the fire resistance of steel formwork may vary depending on factors such as steel thickness, formwork design, and fire protection measures at the construction site. It is recommended to consult professionals and adhere to fire safety regulations and guidelines when using steel formwork in construction projects.

- Q: Can steel formwork be used for both small and large concrete pours?

- Yes, steel formwork can be used for both small and large concrete pours. Steel formwork is highly versatile and can be easily adjusted or modified to accommodate different sizes and shapes of concrete structures. It provides high strength and stability, making it suitable for large pours where heavy loads and pressures are involved. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for both small and large construction projects.

- Q: What are the different types of finishes applied to steel formwork surfaces?

- There are several types of finishes that can be applied to steel formwork surfaces. These finishes are designed to enhance the appearance, durability, and performance of the steel formwork. Some of the most common types of finishes include: 1. Galvanized Finish: This is a popular finish for steel formwork surfaces. It involves coating the steel with a layer of zinc, which provides excellent corrosion resistance. Galvanized finishes are often used in outdoor or high-moisture environments. 2. Powder Coating: Powder coating is a process in which a dry powder is electrostatically applied to the steel surface and then cured under heat. This results in a hard, durable finish that is resistant to chipping, scratching, and fading. Powder coatings are available in a wide range of colors and textures. 3. Paint Finish: Paint finishes are commonly used to enhance the aesthetics of steel formwork surfaces. They provide a smooth, uniform appearance and can be customized to match specific color requirements. Paint finishes also provide a level of protection against corrosion and weathering. 4. Epoxy Coating: Epoxy coatings are known for their excellent chemical resistance and durability. They are often used in industrial applications where the steel formwork may come into contact with chemicals, acids, or solvents. Epoxy coatings also offer good adhesion and abrasion resistance. 5. Anodized Finish: Anodizing is a process in which a layer of aluminum oxide is formed on the surface of the steel formwork. This finish provides enhanced corrosion resistance, as well as a decorative appearance. Anodized finishes are commonly used in architectural applications. 6. Stainless Steel Finish: For some steel formwork applications, a stainless steel finish may be preferred. Stainless steel is inherently corrosion-resistant and has a sleek, modern appearance. It is often used in environments with high humidity or exposure to chemicals. These are just a few examples of the different types of finishes that can be applied to steel formwork surfaces. The choice of finish will depend on factors such as the intended use of the formwork, the desired aesthetics, and the environmental conditions it will be exposed to.

- Q: What type of steel is used in steel formwork?

- The type of steel used in steel formwork is typically a high-strength, low-alloy (HSLA) steel. This type of steel is known for its excellent strength, durability, and resistance to corrosion. HSLA steel is commonly used in construction applications where a strong and long-lasting material is required to withstand the rigors of formwork. Additionally, the steel used in formwork is often treated with special coatings or finishes to further enhance its resistance to rust and other forms of degradation.

- Q: What are the different types of formwork ties used in steel formwork?

- There are several different types of formwork ties that are commonly used in steel formwork systems. These ties are essential for holding the formwork panels together and ensuring the stability and strength of the formwork structure. 1. Wedge Tie: This is the most common type of formwork tie used in steel formwork. It consists of a wedge-shaped metal piece that is inserted into a hole in the formwork panel. The wedge is then tightened, creating a strong connection and holding the panels in place. 2. Pin and Wedge Tie: This type of tie consists of a pin and a wedge. The pin is inserted into a hole in the formwork panel and then the wedge is driven into the pin, creating a tight connection. 3. Wing Nut and Tie Rod: This tie system uses a wing nut and a tie rod to hold the formwork panels together. The tie rod is threaded through the panels and secured with a wing nut on each side. This type of tie allows for easy removal and reassembly of the formwork. 4. Coil Tie: A coil tie is a type of tie that is used when the formwork panels need to be secured to the steel reinforcement bars. The tie is threaded through the formwork panel and then wrapped around the reinforcement bar, creating a secure connection. 5. Flat Tie: Flat ties are used to connect the formwork panels in situations where the panels need to be secured tightly against each other. These ties are flat metal strips that are inserted into holes in the formwork panels and then tightened. These are just a few examples of the different types of formwork ties used in steel formwork systems. The choice of tie will depend on factors such as the specific formwork design, the load requirements, and the ease of installation and removal. It is important to select the appropriate tie system to ensure the stability and safety of the formwork structure.

- Q: How does steel formwork contribute to the accuracy of concrete placements?

- Steel formwork contributes to the accuracy of concrete placements by providing a strong and stable structure that holds the concrete in place during the pouring and setting process. The use of steel formwork ensures that the concrete is poured into the desired shape and dimensions, eliminating any potential for deviations or errors. Additionally, the rigid nature of steel formwork prevents any movement or shifting of the concrete, resulting in a more precise and accurate placement.

- Q: How does steel formwork affect the overall thermal insulation of a building?

- Steel formwork has minimal impact on the overall thermal insulation of a building. Since steel is a good conductor of heat, it does not provide sufficient insulation on its own. However, when combined with appropriate insulation materials, such as foam or mineral wool, steel formwork can contribute to a well-insulated building by providing structural support while the insulation material retains heat or cold temperatures.

- Q: How does steel formwork affect the overall construction productivity?

- Steel formwork is a construction technique that utilizes metal panels and supports to create temporary molds or frames for pouring concrete. This method offers several advantages over traditional timber formwork, including enhanced durability, reusability, and flexibility in design. Consequently, steel formwork significantly affects the overall construction productivity in multiple ways. Firstly, steel formwork contributes to increased construction efficiency by reducing the time required for formwork assembly and dismantling. Unlike timber formwork, steel panels are prefabricated and easily interconnected, allowing for swift installation and disassembly. This results in reduced labor hours and faster completion of formwork activities, ultimately accelerating the construction process. Moreover, the durability of steel formwork positively impacts productivity. Steel panels can withstand harsh weather conditions, extreme temperatures, and heavy loads, ensuring their longevity and reusability. As a result, contractors can reuse steel formwork on multiple projects, eliminating the need for frequent replacement and reducing material costs. The ability to reuse formwork not only saves time and money but also minimizes waste generation and promotes sustainability in the construction industry. Additionally, steel formwork offers greater flexibility in design, enabling the construction of complex structures with precision. The modularity and adjustability of steel panels allow for easy customization according to project requirements, resulting in accurate and consistent concrete placements. This precision eliminates the need for excessive concrete rework, reducing material waste and saving construction time. The speed and accuracy provided by steel formwork positively impact overall construction productivity. Furthermore, steel formwork enhances safety on construction sites. Its sturdy structure and secure connections ensure stability during concrete pouring, minimizing the risk of accidents or structural failures. This increased safety reduces downtime caused by injuries or damages, ultimately improving productivity by maintaining a continuous workflow. In conclusion, steel formwork significantly affects overall construction productivity through various means. Its quick assembly and dismantling, durability, reusability, flexibility in design, and improved safety contribute to faster construction processes, reduced material waste, and enhanced efficiency. Embracing steel formwork techniques can lead to significant time and cost savings, ultimately benefiting the construction industry as a whole.

- Q: Are there any specific design considerations for steel formwork systems?

- Yes, there are several specific design considerations for steel formwork systems. These include factors such as the load-bearing capacity of the system, its stability and rigidity, ease of assembly and disassembly, durability, corrosion resistance, and adaptability to different project requirements. Additionally, the design should incorporate safety features like non-slip surfaces, secure connections, and proper bracing to ensure worker safety during construction activities.

Send your message to us

RingLock scaffolding Accessories for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords