Ring Lock Scaffolding Accessories for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Ring-lock Scaffolding

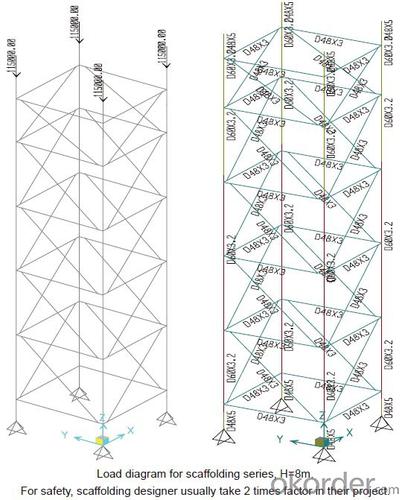

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: Can steel formwork be used for both small and large-scale construction projects?

- Indeed, steel formwork proves to be applicable for construction projects of both small and large scales. It presents numerous advantages, including durability, reusability, and flexibility. Its ability to endure immense pressure and loads renders it suitable for extensive projects necessitating substantial concrete pouring. Moreover, the modular nature of steel formwork permits effortless customization and adaptation to diverse project sizes and designs. This characteristic renders it equally fit for smaller construction projects that require a swift and effective formwork system. Additionally, steel formwork guarantees a polished and superior finish to concrete structures, ensuring a uniform appearance irrespective of the project magnitude. All in all, steel formwork emerges as a versatile and dependable option for construction projects, be they small or large in scale.

- Q: Is steel formwork suitable for projects with limited construction space?

- Indeed, projects with limited construction space can benefit greatly from the utilization of steel formwork. Renowned for its adaptability and capacity to be tailored to different project specifications, especially those constrained by space restrictions, steel formwork stands as a lightweight and resilient alternative. Its inherent feasibility in terms of assembly, disassembly, and mobility further contributes to optimal space utilization. Moreover, steel formwork guarantees a remarkable level of precision and accuracy, facilitating a seamless and efficient construction process within the confines of limited space.

- Q: Can steel formwork be used for decorative concrete finishes?

- Yes, steel formwork can be used for decorative concrete finishes. It provides sturdy support and precise shaping, allowing for intricate designs and smooth finishes in decorative concrete applications.

- Q: How are steel formwork systems assembled and disassembled?

- Steel formwork systems are assembled and disassembled using a simple and efficient process. The assembly starts by erecting the steel panels, which are designed to interlock with each other through various connecting devices such as pins, wedges, or clips. These panels come in different sizes and shapes to accommodate various construction requirements. To assemble the steel formwork system, the panels are aligned and connected together according to the desired shape and dimensions of the structure. The panels are typically secured using pins or wedges to ensure stability and prevent any movement during the concrete pouring process. Once the panels are properly connected, the next step involves installing the necessary support structures such as walers, props, and braces. These elements help to reinforce the formwork system and distribute the loads evenly. Walers are horizontal beams that connect the vertical panels, while props are adjustable vertical supports that provide additional stability. Braces are diagonal members that help in resisting lateral forces. During the concrete pouring process, the steel formwork system holds the wet concrete in place and provides the desired shape and finish to the structure. After the concrete has cured and gained sufficient strength, the dismantling process begins. To disassemble the steel formwork system, the props and braces are removed first, followed by the walers. Once the support structures are taken down, the panels can be easily detached from each other by removing the connecting devices. This can be done by either pulling out the pins or wedges or releasing the clips. The disassembly process is usually done systematically, starting from the top and moving downwards to ensure safety and prevent any accidental collapse. It is important to follow proper safety guidelines and use appropriate tools to avoid any damage to the formwork system or injury to the workers. In conclusion, steel formwork systems are assembled by connecting steel panels and installing support structures, while the disassembly process involves removing the support structures and disconnecting the panels. This systematic approach ensures a safe and efficient construction process, allowing for the reuse of the formwork system in future projects.

- Q: Can steel formwork be used for precast concrete tanks?

- Certainly, precast concrete tanks can indeed utilize steel formwork. Steel, well-known for its strength, durability, and versatility, is a favored option for formwork. It supplies the essential support and structure for pouring and curing the concrete, guaranteeing the tank's desired dimensions and structural soundness. The design and fabrication of steel formwork can be tailored to meet the specific demands of precast concrete tanks, facilitating precise and efficient construction. Furthermore, steel formwork can be utilized multiple times, resulting in a cost-effective approach for producing precast concrete tanks.

- Q: Are there any limitations to using steel formwork?

- Yes, there are some limitations to using steel formwork. Firstly, steel formwork is relatively expensive compared to other types of formwork materials such as wood or plastic. This can make it less cost-effective for smaller projects or projects with a limited budget. Secondly, steel formwork is heavy and requires heavy lifting equipment for installation and removal. This can be a challenge in areas with limited access or where cranes and other heavy machinery may not be readily available. Additionally, steel formwork requires skilled labor for proper installation and dismantling. It is important to have experienced workers who are familiar with the use of steel formwork to ensure the safety and effectiveness of the formwork system. Furthermore, steel formwork is susceptible to corrosion if not properly protected. This can be a concern in environments with high humidity or exposure to moisture, requiring additional maintenance and protective measures. Lastly, steel formwork is not as flexible or adaptable as other types of formwork materials. It may not be suitable for complex or irregular shapes and may require more time and effort to customize for specific project requirements. Overall, while steel formwork offers durability and strength, its limitations in terms of cost, weight, labor requirements, susceptibility to corrosion, and flexibility should be considered when choosing the most appropriate formwork system for a specific construction project.

- Q: Can steel formwork be used for both reinforced and non-reinforced concrete structures?

- Yes, steel formwork can be used for both reinforced and non-reinforced concrete structures. Steel formwork is a versatile and durable option that can withstand the pressure exerted by the concrete during the casting process. It can be easily assembled and disassembled, making it suitable for various types of construction projects. Whether it is a reinforced structure that requires additional support for the reinforcement bars or a non-reinforced structure that only requires a temporary mold, steel formwork can be used effectively in both cases. Its strength and stability allow for the creation of precise shapes and dimensions, ensuring the desired outcome for any concrete structure.

- Q: How does steel formwork affect the cost of construction?

- Steel formwork can significantly impact the cost of construction in various ways. Firstly, steel formwork is durable and reusable, reducing the need for frequent replacements and ultimately lowering overall costs. Additionally, steel formwork allows for faster construction due to its ease of assembly and disassembly, leading to reduced labor and time expenses. Moreover, steel formwork provides superior strength and stability, which can reduce the need for additional structural support, resulting in cost savings. Finally, the flexibility of steel formwork enables it to be customized to different project requirements, optimizing material usage and minimizing waste, further impacting construction costs positively.

- Q: Can steel formwork be used for both horizontal and vertical structures?

- Yes, steel formwork can be used for both horizontal and vertical structures. Steel formwork is a versatile construction material that can be easily adjusted and reused, making it suitable for various types of structures. It provides excellent strength and stability, making it ideal for supporting heavy concrete loads in both horizontal and vertical applications. Steel formwork systems can be customized and assembled to meet the specific requirements of different construction projects, allowing for efficient and precise construction of both horizontal slabs and vertical walls. Its durability and resistance to wear and tear make it a reliable choice for long-term use in various construction applications.

- Q: Can steel formwork be used in earthquake-prone areas?

- Indeed, in earthquake-prone areas, steel formwork proves to be a viable option. Due to its robustness and endurance, steel can withstand the immense forces generated during an earthquake. Its tensile strength is exceptional, enabling it to resist deformation or collapse when subjected to seismic loads. As a result, steel formwork systems are intentionally constructed to be rigid and stable, providing a secure and dependable solution for erecting buildings and structures in regions susceptible to earthquakes. Additionally, the reusability of steel formwork makes it an economically advantageous choice for construction projects in these locations. Nevertheless, it is imperative to ensure that the design and installation of the steel formwork adhere to the specific seismic requirements and regulations of the particular area, thus guaranteeing the utmost safety.

Send your message to us

Ring Lock Scaffolding Accessories for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords