Reynolds Aluminum Foil Sheets for Deep Drawing Cup Hot Rolled Aluminium Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

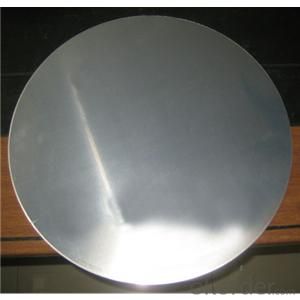

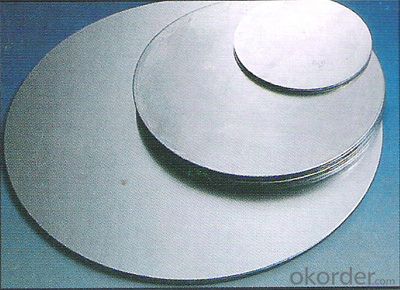

1.Structure of Hot Rolled Aluminium Circles for Deep Drawing Cup

Hot Rolled Aluminium Circles for Deep Drawing Cup is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Hot Rolled Aluminium Circles for Deep Drawing Cup

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: This question asks for an identification of various types of aluminum sheets that are typically utilized in construction projects.

- <p>Aluminum sheets used in construction come in various types, each with specific properties and applications. Common types include: 1) Mill Finish Sheets: These have a natural aluminum finish and are used for applications requiring a raw aluminum look. 2) Painted Aluminum Sheets: Coated with paint for enhanced durability and color options, suitable for exterior applications. 3) Anodized Aluminum Sheets: Durable and corrosion-resistant, often used for architectural features. 4) Embossed Aluminum Sheets: Offered with various textures for design purposes. 5) Perforated Aluminum Sheets: Used for decorative or functional purposes, such as ventilation. 6) Aluminum Composite Material (ACM) Sheets: Consisting of two aluminum sheets with a non-aluminum core, used for cladding. Each type is chosen based on the project's specific requirements for aesthetics, strength, and environmental resistance.</p>

- Q: The user is inquiring if it's possible to incorporate recycled aluminum sheets into their project.

- <p>Yes, you can use recycled aluminum sheets in your project. Recycled aluminum is not only environmentally friendly but also cost-effective. It maintains the same strength and durability as new aluminum, making it suitable for various applications. Ensure the recycled aluminum meets your project's specifications and quality standards. Always check for any impurities or inconsistencies that might affect the performance of your project. Using recycled materials can also contribute to sustainability and reduce waste.</p>

- Q: Hey.How come iron rust and aluminium does not?DETAILED ANSWER PLEASE.I want to understand this...THANKS.

- Rust And Aluminum

- Q: how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

- Q: What are the different methods of forming aluminum sheet?

- There are several methods of forming aluminum sheet, including rolling, extrusion, stamping, and spinning.

- Q: Can aluminum sheets be reused or recycled after their initial use?

- <p>Yes, aluminum sheets can be recycled again after use. Aluminum is one of the most recycled materials globally due to its low cost of recycling and its ability to retain its properties even after multiple recycling processes. Recycling aluminum saves energy compared to producing new aluminum from raw materials, and it helps reduce waste in landfills.</p>

- Q: This question asks for the duration aluminum sheets can last and how their lifespan compares to other materials.

- <p>The lifespan of aluminum sheets can vary depending on the environment and usage, but generally, they can last for several decades with proper care and maintenance. Aluminum's resistance to corrosion and weathering makes it a durable choice. Compared to other materials, aluminum is more durable than wood and many plastics, but it may not last as long as some high-quality stainless steels or certain types of stone. It's also lighter than steel, making it a popular choice for construction and manufacturing applications where weight is a concern.</p>

- Q: Are 101 aluminum sheets available in different finishes (e.g., brushed, polished)?

- Yes, 101 aluminum sheets are available in different finishes such as brushed and polished. These finishes are achieved through various processes that result in different textures and appearances on the surface of the aluminum sheets. Brushed finishes are created by brushing the surface of the sheet with an abrasive material, which creates a pattern of fine lines. This finish is commonly used to create a matte appearance. On the other hand, polished finishes are achieved by polishing the surface of the sheet to a high shine. This finish is often used to create a reflective and smooth surface. So, depending on the desired aesthetic or functional requirements, one can choose between brushed or polished finishes for 101 aluminum sheets.

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets are known for their excellent weather resistance properties. Due to their inherent corrosion resistance, aluminum sheets can withstand exposure to various weather conditions without deteriorating or rusting, making them highly suitable for outdoor applications. The protective oxide layer that naturally forms on the surface of aluminum provides a barrier against moisture, preventing the metal from reacting with oxygen and thus reducing the risk of corrosion. Additionally, aluminum sheets have high resistance to UV radiation, making them resistant to fading or discoloration caused by prolonged exposure to the sun. Overall, aluminum sheets offer exceptional performance in terms of weather resistance, making them a reliable choice for a wide range of outdoor applications, including roofing, siding, and outdoor signage.

- Q: Can the aluminum sheets be used for manufacturing decorative trim?

- Indeed, the utilization of aluminum sheets is viable for the production of decorative trim. Being a versatile substance, aluminum is renowned for its lightweight nature, durability, and exceptional resistance to corrosion. It bestows the convenience of effortless shaping and molding into diverse decorative configurations and motifs. Furthermore, aluminum's aesthetic allure can be accentuated by applying coatings or paints of assorted hues. Consequently, aluminum sheets emerge as a highly favored option for fabricating decorative trim across a multitude of sectors, encompassing architecture, automotive, and interior design.

Send your message to us

Reynolds Aluminum Foil Sheets for Deep Drawing Cup Hot Rolled Aluminium Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords