Homemade Dryer Sheets Aluminum Foil Mill Finished Aluminium Circle for Drawing Cup

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

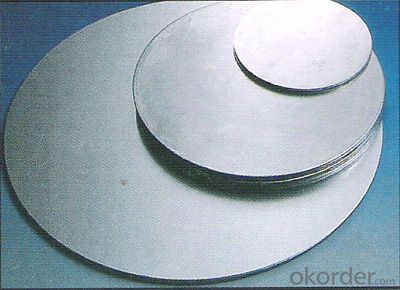

1.Structure of Mill Finished Aluminium Circle for Drawing Cup

Mill Finished Aluminium Circle for Drawing Cup is one semi-finished aluminium material. This Aluminium Circle is widly used to produce aluminium pot, especially for spinning The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Mill Finished Aluminium Circle for Drawing Cup

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

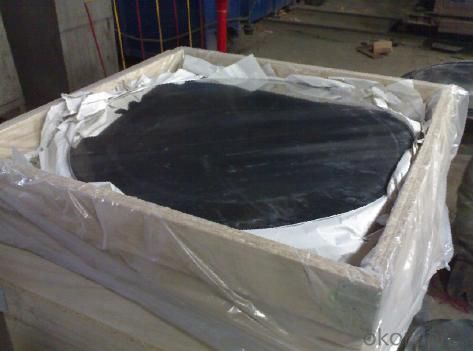

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Diameter | Weight |

| AA1050 | H14 | 0.2MM-2MM | 100MM-1000MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the thickness of an aluminum sheet?

- The specific application and requirements determine the variability in the thickness of an aluminum sheet. A wide variety of thicknesses, usually ranging from 0.006 inches (0.15mm) to 0.25 inches (6.35mm) or even more, can be found in aluminum sheets. Gauge is the usual unit of measurement for thickness, where higher gauge numbers indicate thinner sheets. To choose the right thickness for an aluminum sheet, one must consider the intended use and desired properties like strength, flexibility, or weight.

- Q: Can aluminum sheet withstand heavy loads?

- Yes, aluminum sheet can withstand heavy loads. Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for applications that require durability and load-bearing capabilities. Aluminum sheets are commonly used in industries such as aerospace, automotive, construction, and marine, where heavy loads are involved. Additionally, aluminum's inherent corrosion resistance further enhances its ability to withstand heavy loads over extended periods. However, it is important to consider the specific grade and thickness of the aluminum sheet, as different alloys and thicknesses have varying load capacities.

- Q: How to distinguish fluorocarbon spraying and powder spraying aluminium plate

- 3, powder coating is spraying equipment (electrostatic spray machine) the powder coating is sprayed onto the surface of the workpiece under the electrostatic interaction, the powder will be uniformly adsorbed on the surface of the workpiece, the formation of powder coating; powder coatings after high temperature baking leveling curing, into effect (different effect of different kinds of powder coatings in the final) powder coating; spraying effect on mechanical strength, adhesion, corrosion resistance, aging resistance and superior cost in spray painting process, under the same effect.

- Q: Is it possible to utilize recycled aluminum scraps as an alternative to purchasing new aluminum sheets for a project?

- <p>Yes, you can use recycled aluminum scraps in your project instead of buying new aluminum sheets. Recycled aluminum is not only environmentally friendly but also cost-effective. It has similar properties to new aluminum, making it suitable for many applications. However, ensure the quality and purity of the recycled aluminum meet your project's requirements. Check for any impurities or inconsistencies that might affect the strength or performance of your final product. If the recycled aluminum is in good condition and appropriate for your needs, it can be a sustainable and economical choice.</p>

- Q: Aluminum plate thickness 1 cm, iron plate thickness 0.15 cm, area 1 square meters, thank you

- It's too difficult. Just think about it

- Q: Cooks are warned not to use aluminum cookware when preparing acidic foods. Why?

- The reacton will make the food taste bad..metalic. Aluminun will poisen your body. We should never use alluminum cookware.

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum size of aluminum sheets can differ based on the manufacturer and specific use. Nonetheless, as a rule, aluminum sheets typically have a standard maximum size of 4 feet by 12 feet (48 inches by 144 inches). This size is widely employed across industries like construction, automotive, and aerospace. Nevertheless, it is crucial to acknowledge that certain suppliers may offer larger sizes upon request, albeit with additional expenses and factors to consider.

- Q: Can aluminum sheets be used for interior design purposes?

- Yes, aluminum sheets can be used for interior design purposes. They are versatile, lightweight, and durable materials that can be used for various applications such as wall cladding, ceilings, countertops, backsplashes, and decorative accents. Aluminum sheets offer a modern and sleek aesthetic, and their availability in different finishes and colors allows for customization to fit various design styles and preferences.

- Q: This question asks for a list of various types of aluminum sheets that can be used for decorative purposes.

- <p>Aluminum sheets are popular for decorative purposes due to their durability and versatility. The main types include: 1) Embossed Aluminum Sheets, which feature a textured surface for a unique look; 2) Perforated Aluminum Sheets, with holes of various sizes for a distinctive pattern; 3) Mirror Finish Aluminum Sheets, offering a reflective, shiny appearance; 4) Anodized Aluminum Sheets, which have a protective oxide layer for enhanced color and durability; 5) Brushed Aluminum Sheets, with a satin-like finish; 6) Color Coated Aluminum Sheets, available in a wide range of colors; 7) Composite Aluminum Panels, which combine aluminum with other materials for added strength and design options. Each type offers specific aesthetic and functional benefits for various decorative applications.</p>

- Q: Are aluminum sheets suitable for lightweight structures?

- Yes, aluminum sheets are suitable for lightweight structures. Aluminum is known for its low density and high strength-to-weight ratio, making it an ideal material for lightweight applications. Aluminum sheets are commonly used in industries such as aerospace, automotive, and construction, where weight reduction is crucial. They offer excellent corrosion resistance, durability, and formability, allowing for easy fabrication and installation. Additionally, aluminum sheets can be easily joined using various welding and adhesive techniques, further enhancing their suitability for lightweight structures.

Send your message to us

Homemade Dryer Sheets Aluminum Foil Mill Finished Aluminium Circle for Drawing Cup

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords