Revere Ware Prime Quality Stainless Steel Baking Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Sheet with prime quality

Features Stainless Steel Sheet with prime quality:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

Detail information Stainless Steel Sheet with prime quality:

1. Steel grade: 321

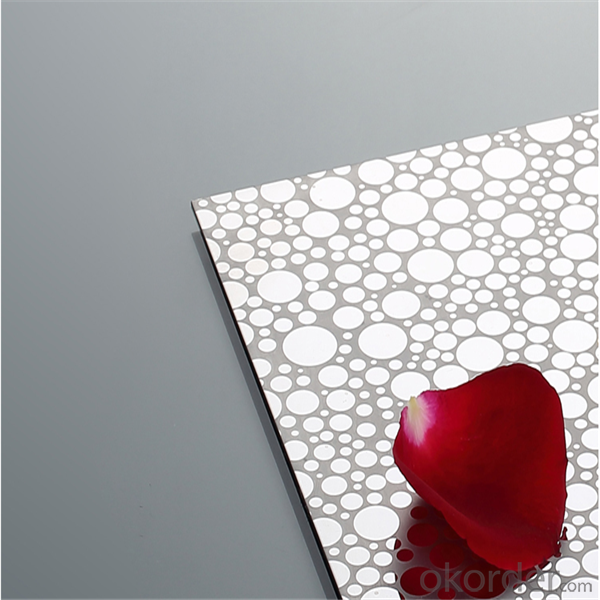

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

6. Standard: AISI, SUS, etc.

1. Specifications about Stainless Steel Sheet with prime quality

Commodity | Stainless Steel Sheet with prime quality |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 5 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

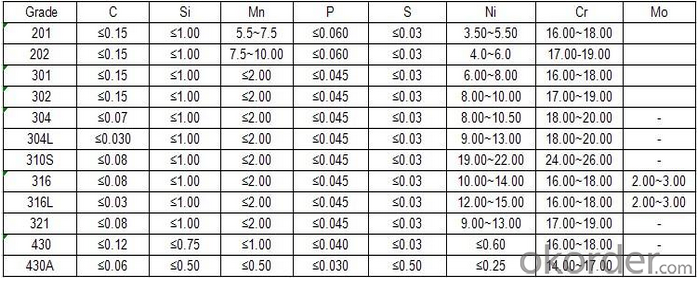

2. Chemical Composition about stainless steel sheet

- Q:Can stainless steel sheets be used in construction projects?

- Yes, stainless steel sheets can be used in construction projects. Stainless steel is a versatile and durable material that is commonly used in various construction applications. It is known for its corrosion resistance, which makes it suitable for outdoor and high-moisture environments. Stainless steel sheets are often used for roofing, wall cladding, structural components, and decorative features in buildings. They can also be used for interior applications such as countertops, backsplashes, and elevator panels. Additionally, stainless steel sheets are available in various finishes and textures, allowing for customization and aesthetic appeal in construction projects.

- Q:What is the maximum thickness available for stainless steel sheets?

- The maximum thickness available for stainless steel sheets can vary depending on the specific grade of stainless steel and the manufacturing capabilities of the supplier. However, in general, stainless steel sheets can be found in thicknesses ranging from 0.5mm to 80mm. It is important to note that thicker sheets are typically used for specialized applications that require increased strength and durability, such as construction projects or heavy machinery. When selecting stainless steel sheets, it is crucial to consider the intended use and consult with a reputable supplier to ensure that the desired thickness is available.

- Q:Are stainless steel sheets resistant to corrosion?

- Yes, stainless steel sheets are generally highly resistant to corrosion due to the presence of chromium in their composition, which forms a protective oxide layer on the surface. This oxide layer acts as a barrier, preventing the metal from being exposed to corrosive elements and ensuring its durability in various environments.

- Q:Can stainless steel sheets be used for walkways and platforms?

- Yes, stainless steel sheets can be used for walkways and platforms. Stainless steel is a durable and corrosion-resistant material, making it suitable for outdoor applications. It provides strength and stability, making it a popular choice for constructing walkways and platforms in various industries, including industrial, commercial, and architectural settings.

- Q:Can stainless steel sheets be used for outdoor railings?

- Yes, stainless steel sheets can be used for outdoor railings. Stainless steel is a popular choice for outdoor applications due to its durability and resistance to corrosion. It is able to withstand exposure to various weather conditions, such as rain, snow, and sunlight, without deteriorating or rusting. Stainless steel railings provide a sleek and modern look to outdoor spaces, while also offering strength and stability. Additionally, stainless steel is low maintenance and easy to clean, making it an ideal material for outdoor railings that may be subjected to dirt, dust, or other debris. Overall, stainless steel sheets are an excellent choice for outdoor railings, offering both aesthetic appeal and long-lasting performance.

- Q:What are the different types of edge profiles for stainless steel sheets?

- There are several different types of edge profiles that can be applied to stainless steel sheets, depending on the desired aesthetic and functional requirements. Some of these edge profiles include: 1. Square Edge: This is the most basic and common edge profile for stainless steel sheets. It features a straight, square edge without any additional shaping or finishing. 2. Beveled Edge: A beveled edge is achieved by cutting and shaping the edge of the stainless steel sheet at an angle. This profile adds a slight slope or chamfer to the edge, giving it a more refined and polished appearance. 3. Rounded Edge: Also known as a bullnose edge, this profile involves rounding off the sharp edges of the stainless steel sheet. It creates a smooth and curved edge that minimizes the risk of injuries from sharp corners. 4. Full Radius Edge: This edge profile involves creating a complete semicircular or rounded edge along the length of the stainless steel sheet. It offers a more pronounced curved appearance compared to a rounded edge. 5. Ogee Edge: An ogee edge profile features a double curve, with one concave curve followed by a convex curve. It adds an elegant and decorative touch to the stainless steel sheet, making it suitable for applications that require a more ornamental look. 6. Dupont Edge: This edge profile is characterized by a straight edge with a small bevel on the top and bottom sides of the sheet. It offers a sleek and modern appearance, often used in contemporary design applications. 7. Knife Edge: A knife edge profile involves sharpening the edge of the stainless steel sheet to create a thin, sharp edge. This profile is commonly used for applications where a precise and clean-cut appearance is desired. These are just a few examples of the different edge profiles available for stainless steel sheets. The choice of edge profile depends on the intended use, style preferences, and specific requirements of the project at hand.

- Q:What welding equipment do we need for welding stainless steel sheet and stainless steel square tube?

- 1 mm thick enough, basically argon arc welding machine can, 0.2 thick stainless steel plate welding is not good ah, how have three or four points it can be positive or negative, only a few joints only, mainly to see the technology myself you, not what, the polishing wheel is on the line let's do it, you can buy a good quality of argon arc welding machine, the high price of the arc is stable

- Q:Are stainless steel sheets resistant to fire?

- Yes, stainless steel sheets are highly resistant to fire. Stainless steel is a type of metal alloy that contains a high percentage of chromium, which forms a protective layer of chromium oxide on the surface when exposed to air or moisture. This chromium oxide layer acts as a barrier, preventing oxygen from reaching the underlying metal and thus making stainless steel highly resistant to corrosion and fire. Stainless steel sheets have a melting point of around 2750°F (1510°C), which is significantly higher than the temperatures typically encountered in most fire scenarios. This means that stainless steel can withstand intense heat for a prolonged period without deforming or losing its structural integrity. Furthermore, stainless steel is non-combustible and does not contribute to the spread of flames. It does not release harmful gases or toxic fumes when exposed to fire, making it a safe material for use in various applications where fire resistance is crucial, such as in building construction, industrial equipment, and transportation. Due to these properties, stainless steel sheets are widely used in fire-rated structures, including fire doors, fire-rated walls, and fire-resistant enclosures. They provide an effective barrier against the heat and flames, helping to contain the fire and protect the surrounding areas. However, it is important to note that while stainless steel is highly resistant to fire, it can still be affected by extremely high temperatures or prolonged exposure to fire. In such cases, the material may experience some degree of distortion or damage. Therefore, it is essential to consider the specific fire rating requirements and consult with experts to ensure the appropriate selection and installation of stainless steel sheets in fire-resistant applications.

- Q:Are stainless steel sheets resistant to acetic acid?

- Yes, stainless steel sheets are generally resistant to acetic acid. Acetic acid is a weak acid and does not cause significant corrosion or damage to stainless steel. However, prolonged exposure to highly concentrated or boiling acetic acid may cause some corrosion or staining on the surface of the stainless steel. It is important to note that the resistance of stainless steel to acetic acid can vary depending on the specific grade and composition of the stainless steel.

- Q:What are the different types of stainless steel sheet surface coatings available?

- Different types of surface coatings are available for stainless steel sheets, each providing unique properties and advantages. Some of the most common types are: 1. Natural Finish: Stainless steel sheets without any coating have a smooth and natural surface. This type is commonly used when corrosion resistance is essential. 2. Brushed Coating: This coating creates a distinctive brushed pattern on the stainless steel surface. It adds a decorative touch while also concealing scratches and fingerprints. 3. Mirror Coating: A mirror finish coating gives stainless steel sheets a highly reflective surface, similar to a mirror. This type is popular in architectural and decorative applications. 4. Satin Coating: Satin coatings offer a smooth and matte appearance with low reflectivity. They are often used in high-end appliances and architectural elements. 5. Bead Blasted Coating: This coating creates a uniform and textured surface by bombarding the stainless steel with small glass beads. It provides a unique visual effect and can hide surface imperfections. 6. Patterned Coating: Patterned coatings involve embossing or etching designs onto the stainless steel surface. They can create various patterns and textures, enhancing the aesthetic appeal in different applications. 7. Colored Coatings: Stainless steel sheets can be coated with different colors using processes like powder coating or electroplating. This allows for customization and adds a decorative element to the material. When choosing a surface coating for stainless steel sheets, it is important to consider the specific requirements of your application. Factors such as corrosion resistance, durability, aesthetics, and functionality should all be taken into account to ensure the best choice for your needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Revere Ware Prime Quality Stainless Steel Baking Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords