Reinforcing Twisted Steel Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Reinforcing Twisted Steel Bars

Description of Reinforcing Twisted Steel Bars

1, Diameter: 5.5mm-10mm Reinforcing Twisted Steel Bars

10m- 40mm Reinforcing Twisted Steel Bars

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Reinforcing Twisted Steel Bars

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

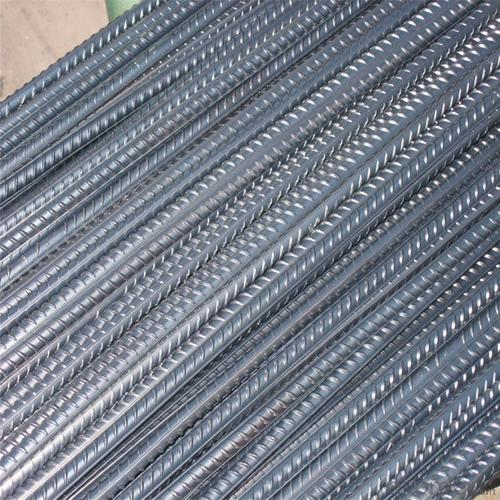

Products Show of Reinforcing Twisted Steel Bars

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different types of tool and die steel?

- There are several different types of tool and die steel, including high-speed steel, cold work steel, hot work steel, and plastic mold steel.

- Q: How does special steel contribute to the transportation sector?

- Special steel contributes to the transportation sector by providing high-strength and lightweight materials that enhance the performance, efficiency, and safety of vehicles. It is used in various components, such as engine parts, chassis, and suspension systems, to improve fuel economy, reduce emissions, and enhance durability. Additionally, special steel's corrosion resistance properties make it suitable for manufacturing components in harsh environments, such as marine and aerospace applications, further expanding its contribution to the transportation industry.

- Q: What are the different heat treatment processes for special steel?

- Some of the different heat treatment processes for special steel include annealing, quenching and tempering, hardening, case hardening, and precipitation hardening.

- Q: How are tungsten alloys used in the defense industry?

- Tungsten alloys are commonly used in the defense industry due to their exceptional properties such as high density, strength, and resistance to heat and corrosion. These alloys are used in various applications including armor piercing ammunition, kinetic energy penetrators, and armor plating for military vehicles and aircraft. Their ability to withstand extreme conditions and penetrate hardened targets make tungsten alloys vital for enhancing the effectiveness and protection capabilities of defense systems.

- Q: How does special steel withstand high-velocity impacts?

- Special steel is able to withstand high-velocity impacts due to its exceptional strength and toughness. It is specifically engineered to have enhanced mechanical properties, such as increased hardness and resistance to deformation. This allows the steel to absorb and distribute the energy from the impact, minimizing the risk of fractures or failure. Additionally, special steel may be heat-treated or alloyed with other elements to further improve its impact resistance, making it an ideal choice for applications where high-velocity impacts are a concern.

- Q: What are the properties and characteristics of special steel?

- Special steel encompasses a type of steel that possesses distinct attributes and qualities, rendering it suitable for particular applications that demand exceptional strength, endurance, and resilience against diverse environmental factors. The properties and characteristics of special steel encompass the following: 1. Remarkable Strength: Special steel is renowned for its extraordinary strength, enabling it to endure heavy loads and extreme circumstances. This renders it ideal for applications requiring structural integrity and durability, such as the construction, automotive, and aerospace sectors. 2. Superb Resistance to Corrosion: Special steel is frequently alloyed with elements such as chromium and nickel, augmenting its resistance to corrosion and oxidation. This characteristic makes it immensely valuable in environments where exposure to moisture, chemicals, or extreme temperatures can rapidly deteriorate conventional steel. 3. Resistance to High Temperatures: Special steel is designed to maintain its mechanical properties and structural integrity even when subjected to elevated temperatures. It demonstrates exceptional thermal stability, making it suitable for applications involving intense heat, such as power generation, the oil and gas industry, and manufacturing processes. 4. Resistance to Wear: Special steel is frequently hardened and treated to enhance its resistance to wear. This trait enables it to withstand abrasive materials, friction, and erosion, making it suitable for cutting tools, machine parts, and wear-resistant components in heavy machinery. 5. Magnetic Characteristics: Certain types of special steel exhibit magnetic properties, rendering them ideal for applications in the electrical and electronics industries. Examples include electrical transformers, motors, generators, and magnetic shielding. 6. Machinability: Special steel is designed to be easily machined, enabling it to be shaped, formed, and fabricated into various components with precision. This attribute is crucial for industries requiring the production of intricate and complex parts in an efficient manner. 7. Cost-effectiveness: Despite possessing unique properties, special steel often proves to be cost-effective compared to other materials with similar performance characteristics. Its long lifespan, resistance to corrosion and wear, and versatility make it the preferred choice for numerous applications, offering a balance between performance and cost. In summary, special steel combines exceptional strength, resistance to corrosion and wear, heat resistance, and magnetic properties, making it a versatile material utilized in diverse industries. Its distinctive properties render it an indispensable component in applications where standard steel or alternative materials would not suffice.

- Q: What are the main applications of special steel in the packaging industry?

- Special steel is widely used in the packaging industry for a range of applications. One of the main uses is in the manufacturing of packaging machinery, such as filling machines, sealing machines, and wrapping machines, where the high strength and durability of special steel components ensure smooth operation and longevity. Additionally, special steel is utilized for the production of packaging tools, like cutters, blades, and molds, which require resistance to wear and corrosion. The use of special steel in the packaging industry helps to enhance productivity, improve product quality, and ensure the safety and integrity of packaged goods.

- Q: How does special steel meet the requirements of specific industries?

- Special steel meets the requirements of specific industries by offering superior mechanical properties, corrosion resistance, and heat resistance, which are essential for various applications. Its tailored composition and precise manufacturing processes ensure the steel can withstand extreme conditions, such as high temperatures, pressure, and harsh environments. Additionally, the versatility of special steel allows for customization to meet specific industry needs, resulting in enhanced performance, durability, and overall efficiency.

- Q: Can special steel be used for making nuclear industry components?

- Yes, special steel can be used for making nuclear industry components. Special steel, also known as alloy steel, possesses certain properties that make it suitable for use in the nuclear industry. These properties include high strength, excellent corrosion resistance, and good resistance to high temperatures and radiation. Nuclear industry components, such as reactor pressure vessels, steam generators, and fuel rods, operate under extreme conditions of high pressure, high temperature, and exposure to radiation. Special steel can withstand these conditions and maintain its structural integrity, ensuring the safe and reliable operation of nuclear facilities. The use of special steel in the nuclear industry also helps to prevent the release of radioactive materials. The high corrosion resistance of special steel reduces the risk of leakage and contamination, thereby enhancing the safety of nuclear power plants. Furthermore, special steel can be tailored to meet specific requirements of the nuclear industry. Different types of special steel alloys can be developed with specific compositions and heat treatments to optimize their properties for nuclear applications. This allows for the customization of steel components to meet the unique demands of the nuclear industry. In conclusion, special steel can indeed be used for making nuclear industry components due to its high strength, corrosion resistance, and resistance to high temperatures and radiation. Its use contributes to the safety and reliability of nuclear facilities, while also allowing for customization to meet specific requirements.

- Q: How does special steel contribute to the aerospace noise reduction?

- Special steel contributes to aerospace noise reduction in several ways. Firstly, it is used in the construction of aircraft engine components such as fan blades and turbine discs. These components are subject to high temperatures and pressure, and special steel helps maintain their structural integrity, reducing vibration and noise. Secondly, special steel is also used in the manufacturing of aircraft fuselage and wings, where it helps dampen vibrations caused by aerodynamic forces, thus reducing noise. Additionally, special steel can be used in the production of sound-absorbing materials, which are used to line the interior of aircraft cabins, further reducing noise levels and improving passenger comfort. Overall, the use of special steel in various aerospace applications plays a crucial role in minimizing noise and improving the overall acoustic performance of aircraft.

Send your message to us

Reinforcing Twisted Steel Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords