Reinforcement Steel Price - High Grade Hot Rolled Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Reinforcing bar (Rebar) refers to the use of reinforced concrete and prestressed concrete with steel, its cross section is round, sometimes for the square with rounded corners. Including light round bar, ribbed steel bar, torsion bar. Reinforced concrete with steel bar is refers to the reinforced concrete reinforcement with straight or plate of strip steel, its appearance is divided into two kinds, light round steel and deformed steel delivery status for the straight bar and wire rod in two. Light round bar is really a small round steel and ordinary low carbon steel wire rod. Deformation is surface ribbed steel bar, usually with 2 longitudinal and cross rib of uniform distribution along the length direction. The appearance of cross rib is spiral, chevron, crescent 3 kinds. With nominal diameter mm number representation. Equals the nominal diameter is equal to the cross section deformation of reinforced light round bar nominal diameter. Reinforcement of nominal diameter is 8-50 mm, recommends to the diameter of 8, 12, 16, 20, 25, 32 and 40 mm. Steel grade: 20 mnsi, 20 mnsi MNV, 25, BS20MnSi. Rebar in concrete main tensile stress. Deformed bars as a result of the action of rib, and concrete have larger bonding ability, thus better able to withstand the role of external force. Steel is widely used in various building structures. Especially large, heavy, light thin wall and high-rise building structure.

Steel processing, steel processing to table and design review, check the material list for errors and omissions, for each steel bar to press

Material list to check whether meet the requirements, after these two checks, then press the material list sent out samples, trial production of qualified rear can batch production, processing and good reinforcement to neatly stacked in order.

Construction such as the need to be reinforced by substitution, must fully understand the design intent and substitution material performance, strictly abide by the current design code of reinforced concrete rules, not to area such as the substitution of low strength of high strength steel reinforcement. Any important parts of a reinforced substitution, shall agree with the consent of party a, design unit, and have a written notice shall be substitution.

(1) the steel surface should be clean, sticky oil, dirt, rust must be cleaned before use, can be combined with cold-drawn rust removal process.

(2) reinforced straightening, usable mechanical or manual straightening. After straightening of steel can not have local small bending, die bending, wavy, its surface scars should not be made of steel decreases by 5%.

(3) the steel bar cutting should be according to the number, diameter, length and quantity, the length is tie-in, first cutting long expected, by cutting short expected to reduce short head, and shorten the steel to save steel.

(4) steel hook or bend:

1) steel hook. There are three kinds of forms, respectively semicircle hook, hook and hook. After bending, bend endothelial contraction, skin

Extension, axis length is constant, bend arc formation, size is greater than the baiting size after bending, bending modifier should be considered.

Reinforced bending diameter of 2.5 d heart, straight part for 3 d. Steel hook increase the length of the theoretical calculation value: counter rotating round hook is 6.25 d, the straight

Hook is 3.5 d, the hook is 4.9 d.

(2) the bending of steel. Middle bending diameter D bend, not less than five times the diameter of the reinforcing steel bar.

(3) the stirrup. Stirrups should be done at the end of the hook, hook form should meet the design requirements. Stirrup adjustment, is the hook to increase the length and bending adjustment

Value or the difference between the two and, according to the amount of stirrup outsourcing size or inside the package size.

(4) reinforced blanking length should be according to the component size, concrete cover thickness, rebar bend modifier and hook to increase the length of the provisions as comprehensive exam

Lv.

A. straight reinforced blanking length = member length - protective layer thickness increase length + hook,

B. turn up steel blanking length = straight length - bend modifier + + inclined curved length increase length of hook,

C. blanking length = stirrup stirrup inner perimeter + modifier + hook to increase length of stirrup.

- Q:How do steel rebars resist abrasion in concrete structures?

- Steel rebars resist abrasion in concrete structures due to their high tensile strength and durability. When embedded within the concrete, the rebars act as reinforcement, providing additional strength to the structure. During the setting and hardening process of concrete, rebars are firmly embedded within the mixture, creating a strong bond. This bond ensures that the rebars remain securely in place, even when subjected to external forces such as abrasion. The surface of steel rebars is typically treated to enhance their resistance to abrasion. This can include processes such as hot-dip galvanizing or epoxy coating. These surface treatments create a protective layer that shields the rebars from the abrasive effects of the surrounding concrete and other external factors. Furthermore, steel rebars are designed with ridges or deformations along their surface. These ridges increase the surface area of the rebars, promoting a stronger bond with the concrete. This increased bond helps to distribute external forces, such as abrasion, more evenly throughout the structure, reducing the risk of localized damage. In summary, the high tensile strength, durability, and surface treatments of steel rebars, along with their ability to form a strong bond with concrete, enable them to resist abrasion in concrete structures.

- Q:How do steel rebars contribute to the fire resistance of a structure?

- Steel rebars contribute to the fire resistance of a structure by providing strength and stability to the building's concrete components. In the event of a fire, the rebars help prevent the concrete from cracking or collapsing under high temperatures. The steel has a high melting point, which allows it to maintain its structural integrity even in intense heat. This prolongs the time before the structure reaches its critical failure point, giving occupants more time to evacuate and firefighters more time to control the fire.

- Q:What is the role of steel rebars in beam and column design?

- Steel rebars play a crucial role in beam and column design as they provide reinforcement and enhance the structural integrity of these elements. In reinforced concrete structures, rebars are used to resist tensile forces that concrete alone cannot withstand. In beams, rebars are typically placed at the bottom to counteract tensile stresses caused by bending moments. By distributing the load across the beam's length, rebars effectively increase its strength and prevent cracking or failure. The rebars' ability to resist tension helps the beam maintain its shape and load-bearing capacity, ensuring the structural stability of the entire construction. Similarly, in columns, rebars are placed throughout the length to resist both axial and bending forces. They improve the column's ability to withstand compression while also providing additional resistance against lateral loads from seismic or wind forces. The presence of rebars in columns significantly enhances their load-bearing capacity and overall stability. In summary, steel rebars play a critical role in beam and column design by providing reinforcement against tensile forces, increasing structural strength, preventing cracking, and ensuring the overall stability and safety of the structure.

- Q:Can steel rebars be used in the construction of residential communities?

- Yes, steel rebars can be used in the construction of residential communities. Steel rebars are commonly used in the construction industry for reinforcing concrete structures, including residential buildings. They provide strength and durability to the concrete, improving its load-bearing capacity and resistance to cracks and other forms of structural damage. Steel rebars are often used in residential construction to reinforce foundation footings, walls, columns, and beams. They help to ensure the structural integrity of the building, making it safer and longer-lasting. Additionally, steel rebars can be easily customized and shaped to fit specific design requirements, allowing for flexibility in construction. Overall, the use of steel rebars in residential communities is a common and widely accepted practice in the construction industry.

- Q:How do steel rebars contribute to the crack-resistance of concrete?

- Steel rebars contribute to the crack-resistance of concrete by providing tensile strength to the structure. As concrete is strong in compression but weak in tension, the rebars act as reinforcement, absorbing the tensile forces that may lead to cracks. By distributing these forces throughout the concrete, rebars enhance the overall durability and structural integrity of the concrete, making it less prone to cracking.

- Q:What is the lifespan of a steel rebar in a concrete structure?

- The duration of a steel rebar's existence within a concrete structure may differ due to various factors. Generally, a well-designed and properly constructed concrete structure with steel reinforcement can endure for 50 to 100 years or even longer. One critical factor that affects its lifespan is the quality of the concrete and its ability to shield the steel reinforcement from external elements. Concrete acts as a barrier, safeguarding the steel rebar from moisture, oxygen, and other potentially corrosive substances. However, if the concrete is of inadequate quality, contains excessive amounts of chloride or other aggressive chemicals, or is not adequately cured, it can result in the deterioration of the rebar and significantly reduce its lifespan. Another significant aspect is the exposure conditions to which the concrete structure is exposed. If the structure is situated in a harsh environment with high levels of humidity, exposure to saltwater, or industrial pollutants, it can expedite the corrosion process and decrease the rebar's lifespan. Proper maintenance and periodic inspections can also have a substantial impact on prolonging the steel rebar's lifespan within a concrete structure. Regular inspections can help identify any initial signs of corrosion or deterioration, enabling timely repairs or implementation of protective measures. To enhance the lifespan of steel rebar, additional protective measures can be taken during construction, such as applying corrosion-resistant coatings or utilizing stainless steel reinforcement. These measures can significantly extend the rebar's lifespan and improve the overall durability of the concrete structure. In conclusion, the lifespan of a steel rebar in a concrete structure can vary but generally falls within the range of 50 to 100 years or more, assuming the concrete is of good quality, the exposure conditions are not excessively severe, and proper maintenance and protective measures are implemented.

- Q:Can steel rebars be used in dam construction?

- Yes, steel rebars can be used in dam construction. Steel rebars are commonly used in the construction of dams to reinforce concrete structures and provide added strength and durability. They help to withstand the immense pressure and weight of water, making them an essential component for dam stability and longevity.

- Q:How do steel rebars enhance the load-bearing capacity of a structure?

- Steel rebars enhance the load-bearing capacity of a structure by providing reinforcement and increasing its tensile strength. They are embedded within the concrete, creating a composite material that can withstand higher loads and prevent cracking or failure under stress.

- Q:What is the role of steel rebars in the construction of dams and reservoirs?

- Steel rebars play a vital role in the construction of dams and reservoirs as they provide reinforcement and strength to the concrete structures. These rebars are strategically placed throughout the concrete to enhance its tensile strength, allowing it to withstand the immense pressure exerted by the water. By reinforcing the concrete, steel rebars help prevent cracks and structural failures, ensuring the long-term durability and stability of the dam or reservoir.

- Q:What are the different shapes and forms of steel rebars available?

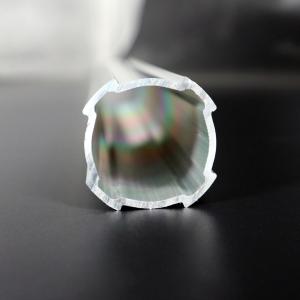

- There are several different shapes and forms of steel rebars available, each designed for specific applications and requirements in construction projects. 1. Plain round bars: These are the most common type of steel rebars and have a circular cross-section. They are used in a wide range of applications, including general construction, reinforcement in concrete slabs, and foundation works. 2. Deformed bars: These rebars have protrusions or deformations on their surface to provide better adhesion with concrete. The deformations increase the bond strength between the rebar and the concrete, making them suitable for applications that require high tensile strength, such as columns, beams, and retaining walls. 3. Square bars: As the name suggests, square rebars have a square cross-section. They are commonly used in applications where a strong bond with concrete is required, such as in precast concrete elements, footings, and walls. 4. Rectangular bars: Rectangular rebars have a rectangular cross-section and are often used in applications that require higher tensile strength, such as bridges, tunnels, and heavy structural elements. 5. Welded wire fabric (WWF): WWF is a prefabricated reinforcement material that consists of a series of longitudinal and transverse wires welded together to form a grid-like pattern. It is commonly used in slabs, walls, and pavements, providing uniform reinforcement distribution. 6. Dowel bars: Dowel bars are used to transfer loads between two adjacent concrete elements, such as connecting slabs or pavements. They are typically made of smooth round bars and are inserted into drilled holes with epoxy adhesive for improved load transfer. 7. T-shaped bars: T-shaped rebars have a T-like cross-section, with a stem and a flange. They are commonly used in applications where additional reinforcement is needed at specific locations, such as joints, corners, and connections. It is important to consider the specific requirements of the construction project and consult with structural engineers or professionals to determine the appropriate shape and form of steel rebars to ensure optimal reinforcement and structural integrity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Reinforcement Steel Price - High Grade Hot Rolled Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords