Nysdot Approved Reinforcement High Strength Geogrids for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

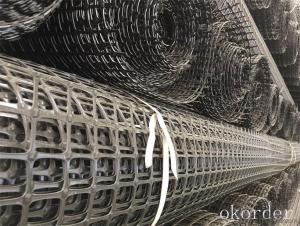

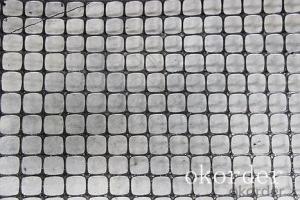

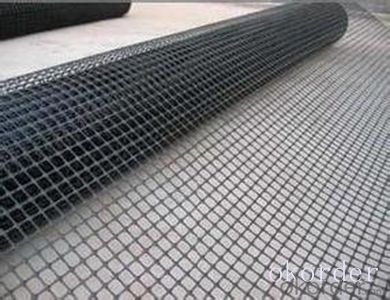

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Geogrids are flat structures, where two or more series of strip elements made of polyester coated with polyethylene, are linked at regular intervals by means of bonding.

Woven Geogrids are flat structures in the shape of a net made of high module synthetic fibres20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Production function

1:Tensile strength, high creep degeneration small, it has good flexibility, low elongation at break, and effectively solved the engineering distortion and quite a shift, adapt to the environment soil, and can meet the retaining wall of high grade highway tall role.

2:Effectively improve the bearing the reinforcement embedded locks, bite role, great enhancement the bearing capacity of the foundation, effective constraint of soil lateral displacement, enhance the foundation stable performance.

3: Compared with the traditional grille has more strength, high bearing capacity is strong, prevent ageing, friction coefficient.

4: Effectively avoid in construction process by a few words of rolling, damage caused by the construction damage.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How much is a square grille

- Warp knitted polyester geogrid, unidirectional tensile plastic geogrid and soil in underground coal mine with two-way stretch plastic biaxially oriented plastic guard net, steel plastic composite geogrid, coal mine with two-way welding plastic top net, high strength spiral rib steel wire grid model, integrated 3D Geomat, high strength geogrid, geocell, engineering fiber, geotextile composite geomembrane, whichincludesimportedwetthinfeltproductionline engineering materials etc..

- Q: Is there any difference between glass fiber grille and geogrid

- Fiberglass geogrid is just a kind of grille,

- Q: Is there a big difference between horizontal permeability and vertical permeability coefficient

- Geomembrane, composite geomembrane, geotextile, geogrid, geotextile, geotextile bags, etc. are called geosynthetics. The coefficient of permeability is a kind of soil properties;

- Q: How are geogrids installed in the field?

- Geogrids are typically installed in the field by first preparing the subgrade by removing any vegetation or loose soil. The geogrid is then rolled out and placed on top of the subgrade, ensuring it is properly aligned and covers the desired area. It is then secured in place using stakes, pins, or other anchoring methods. Finally, the geogrid is covered with a layer of fill material, such as soil or gravel, which is compacted to provide additional stability and load-bearing capacity.

- Q: Can geogrids be used in stormwater detention systems?

- Yes, geogrids can be used in stormwater detention systems. Geogrids provide reinforcement and stability to the soil, improving the overall performance and longevity of the detention system. They help prevent soil erosion and promote proper drainage, making them a suitable choice for stormwater management.

- Q: What are the environmental impacts of using geogrids?

- The environmental impacts of using geogrids can vary depending on factors such as the type of material used, manufacturing processes, and disposal methods. However, some potential impacts include the extraction of raw materials, energy consumption during manufacturing, and the generation of waste and emissions. It is important to consider these factors and ensure proper management and disposal practices to minimize the environmental impacts of using geogrids.

- Q: How do geogrids improve the performance of unpaved roads?

- Geogrids improve the performance of unpaved roads by providing reinforcement and stabilization to the soil. They enhance the load-bearing capacity and reduce deformation and rutting caused by heavy traffic or adverse weather conditions. Geogrids distribute the stresses evenly, preventing the formation of cracks and potholes, thereby increasing the lifespan and durability of the road.

- Q: What are the factors to consider when selecting geogrids for a project?

- When selecting geogrids for a project, there are several factors to consider. These include the specific application or purpose of the project, the site conditions such as soil type and slope stability, the load requirements of the project, the desired lifespan and durability of the geogrids, and the cost-effectiveness and availability of the geogrids. Additionally, it is important to consider the installation process and compatibility with other materials used in the project. By considering these factors, you can ensure that the selected geogrids will effectively meet the needs of your project.

- Q: Can geogrids be used in ground reinforcement for sports fields?

- Yes, geogrids can be used in ground reinforcement for sports fields. Geogrids provide stability, improve load-bearing capacity, and prevent soil erosion, making them a suitable choice for reinforcing the ground in sports fields and ensuring a durable playing surface.

- Q: Geotextiles and geogrids to do the re inspection approach?

- In theory it is necessary

Send your message to us

Nysdot Approved Reinforcement High Strength Geogrids for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords