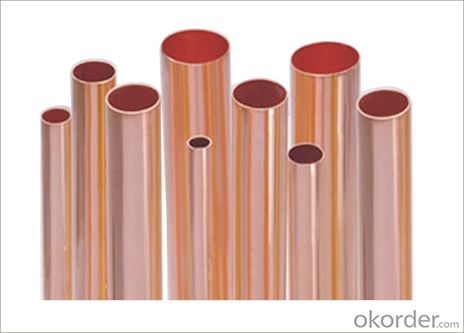

Refrigeration Copper Pipe for New Refrigeration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refrigerant Copper Pipe Type R410A

Model: TP2、TU1、TU2、T2

Application:

Primarily applied in household and commercial central air conditioning system; pressure resistant product made by large water seal extruder through degrease process, without residual oil and with low dust load, suitable for refrigeration systems using new refrigerant

Type Specifications: TP2, TU1, TU2, T2

Primarily applied in household and commercial central air conditioning system; pressure resistant product made by large water seal extruder through degrease process, without residual oil and with low dust load, suitable for refrigeration systems using new refrigerant

Specifications:

Item | air conditioner copper pipe |

Type | straight copper pipe,pancake coil copper pipe,capillary copper pipe |

Standard | GB/T1527-2006,JIS H3300-2006,ASTM B75M,ASTMB42,ASTMB111,ASTMB395, ASTM B359,ASTM B188,ASTM B698,ASTM B640,etc |

Material | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920, C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300, C12500,C14200,C14420,C14500,C14510,C14520,C14530,C17200,C19200, C21000,C23000,C26000,C27000,C27400,C28000,C33000,C33200,C37000, C44300,C44400,C44500,C60800,C63020,C65500,C68700,C70400,C70620, C71000,C71500,C71520,C71640,C72200,etc |

Shape | Round,Square,Rectangular,Oval,half-round |

Outside diameter | 4.76-28.58mm |

Wall thickness | 0.4-1.5mm |

Length | 1m,2m,3m,6m,or as required |

Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard,soft,. |

Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required |

Price Term | Ex-Work,FOB,CNF,CFR,CIF etc |

Payment Terms | TT,L/C etc |

Export to | Singapore,Indonesia,Ukraine,Korea,Thailand,Viet Nam,Saudi Arabia,Brazil,Spain,Canada, USA,Egypt,Iran,India,Kuwait,Dubai,Oman,Kuwait,Peru,Mexico,Iraq,Russia,Malaysia,etc |

MOQ | 2 tons |

Package | Standard export package ,or as required. |

Application | Copper pipe have strong, corrosion resistant properties, and become a modern contractor in all of commodity house pipes, heating, cooling water piping installation of choice |

Contact | If you have any question ,please feel free to contact me we are sure your inquiry or requirements will get prompt attention |

Production Equipment

750-1500kg main frequency induction copper melting furnace, 80MN water seal extruder, LG60 high speed two-roll cold pilger mill, straight-line wire-drawing machine, copper tube/pipe straightener, polisher, 84′ copper coil winding machine, straightening-cutting & pancake coiling machine, thermoplastic packaging machine, 1.2T continuous bright annealing furnace.

80MN extruder

Continuous bright annealing furnace

Testing Devices

spectrum analyzer, atomic absorption analyzer, spectrophotometry, analytical balances, metallurgical microscope, eddy current flaw detector, metal tensile testing machine, eddy conductivity instrument.

Hardness tester

Spectrum analyzer

Metallurgical microscope

Metal tensile testing machine

Atomic absorption analyzer

Process

refined copper — smelting & casting — extrusion — rolling — drawing — straightening-cutting/forming of pancake coil — bright annealing — packaging — finished goods.

Standards

GB/T 1527-2006 Drawn tube of copper and copper alloys

GB/T 16866-2006 Dimensions and tolerances of copper and copper alloy seamless tubes

GB/T 4423-2007 Copper and copper-alloy cold-drawn rod and bar

GB/T 5231-2001 Wrought copper and copper alloys chemical composition limits and forms of wrought products

GB/T 5585.1-2005 Copper or aluminium and its alloy bus bars for electrical purposes—Part 1:Copper andcopper alloy bus bars

GB/T 17791-2007 Seamless copper tube for air conditioner and refrigeration equipment

GB/T 19850-2005 The seamless round copper tubes for electrical purposes

GB/T 26024-2010 Seamless copper and copper alloys tube for valves on air-conditioning and refrigeration system

ASTM B280-2008 Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

EN 12735-1:2001 Copper and copper alloys Seamless,round copper tubes for air-conditioning and refrigeration Part 1:Tubes for piping systems

EN 12735-2:2001 Copper and copper alloy – seamless round copper tube/pipe for air-conditioning and refrigeration system – for equipment

JIS H3300-2009 Seamless copper and copper alloy tube/pipe

- Q: i have an assignment at school about Moonta mining, chosen copper but i have problem with this question

- In addition to soluble copper, you have to consider how copper is extracted from nature. Is it dissolved? or mined in some other way? If mined in some other way, what is the impact of digging into the earth to extract the ore? Whenever you dig a hole in the earth, you create a whole bunch of questions regarding impact. Also, if you scrape off the top of a mountain to get at the ore without digging a hole, what do you do with the unused portion of the mountain? Lots of potential environmental considerations.....once you think about it.

- Q: I found a nickel that appears to be copper. It's 1972 and has a D marking at the bottom. It looks pretty decent condition (not like a parking lot nickel or anything). It appears to be really dark brown. I compared it to a few other older Pennies I have and the brown is definitely darker than copper. I did some google searching and can't find a whole lot. I've heard some mention that it can be copper-clad ? I didn't see too much more about it though. Does anyone know what I have here?

- www.okorder

- Q: There are these earrings that I want to buy that say on the package that they are made of ultra copper alloyed material. Does anyone know what that is and does it TARNISH easily?Thanks.

- Copper alloys are metal alloys that have copper as their principal component. They have high resistance against corrosion. The best known traditional types are bronze, where tin is a significant addition, and brass, using zinc instead. Both these are imprecise terms. Copper is often alloyed with precious metals like silver and gold.

- Q: How would I replace/join a piece of PVC pipe to my copper plumbing ? Would I use copper or PVC joints with some sort of bonding substance ? Or is there a way to repair a leak in copper plumbing/pipes by applying a leak sealer of some kind, if so what kind of sealer is best ? Thanks, much appreciated. ;)

- Copper To Pvc

- Q: How much Copper (solid) can be made by reacting 0.47 moles of Sodium with 26g of Copper(II) Nitrate?2Na(s) + Cu(NO3)2 --> 2NaNO3 + Cu(s)

- This is a very silly question as it is made up by someone who doesn't know their chemistry! If you mix copper nitrate crystals and sodium solid, nothing will happen unless they are left sometime. Then copper nitrate, being deliquescent will absorb water and start to dissolve. Some of the sodium will react with the water. If you try heating the solids together, copper nitrate dissolves in its water of crystallisation before decomposing and again the sodium will react partly with the water. If the copper nitrate is in solution, the sodium will react to a high percentage with the water rather than displacing metallic copper from the copper nitrate solution. 2Na(s) + 2H2O(l) ---> 2NaOH(aq) + H2(g) then Cu2+(aq) + 2OH-(aq) ---> Cu(OH)2(s) Then copper nitrate will be precipitated as copper(II) hydroxide This sort of displacement reaction works fine with other metals eg iron as iron filings, and you can do a Lab on it, but this is stupid doing a question based on misleading chemistry! At most only some of the sodium would displace copper. You can do a calculation assuming it works .. but what is the point with incorrect chemistry? What does that teach you?

- Q: going from galvanized pipe to copper pipe is there any dangers in drinking water?

- It is a code violation to run electrical cords through regular copper or galvanized piping. You have to use piping (called conduit) that is approved specifically for electrical use. Fortunately for you, such conduit is cheap, readily available and easy to install, Go to a building supply center or hardware store and get either thinwall (also called EMT) metal conduit (3/4 diameter will handle most cables) or get electrical PVC which is grey (and thus should blend in with your walls) and easy to install because you simply glue it together. One proviso: you can't run 120 volt power cords AND low voltage cords (like the video or sound cables or the cable company source cable) together in the same conduit. You need separate pipes for 120v power and for communication cables. Another option would be Wiremold, the flat square wiring compartments that mount on the wall for enclosing cables. You can get wide Wiremold with two compartments, one for 120 volt and one for low voltage and communication cables, One thing you have to consider is whether you can fish the cable connections through the conduit. You may need larger diameters thn 3/4 for that. That's why the wiremold, which has a removeable cover, if a preferable product.

- Q: The house needs decorating,There is a doubt: the hall is not directly in the outer wall, the internal and external machines should be separated from a bathroom. So the pipeline to go through the bathroom cabinet, toilet and through these pipes is not good, I think of a way: cabinet drainage can directly discharged in the toilet water (a good processing), and the brass to walk from the ceiling. This raises a question: with the associated copper will certainly be higher than the cabinet itself from the ceiling, this is feasible?

- Split air conditioner is a kind of air conditioner, which is composed of indoor and outdoor units. They are installed indoors and outdoors, and the center is connected by pipes and wires.

- Q: if you had a sheet of copper in a strong permanent magnet, with the plane of the sheet perpendicular to the magnetic field, and quickly jerk it out,a. you will feel no magnetic forceb. any force you feel will be due mainly to iron impurities in the copper itself is not magneticc. you will experience a magnetic force opposing your action d. you will experience a magnetic force assisting your actione. none of these

- C. It's called magnetic or eddy-current damping, and the force is proportional to the speed of plate movement, the conductivity of the copper, the square of the magnetic field strength and the volume of copper in the field. Basically you can think of the copper plate as a series of short-circuited coils which generate circulating currents which in turn generate magnetic fields opposing the motion, not unlike a shorted generator. Since the current increases as the conductivity of the plate does, it's especially noticeable with thick plates of copper and aluminum. (You don't want magnetic materials like iron because the magnetic force will interfere with isolating and feeling the damping force.) When damping force is proportional to velocity it's often called viscous damping, which is just how it feels, like the plate is immersed in honey.

Send your message to us

Refrigeration Copper Pipe for New Refrigeration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords