High Performance Refrigeration Copper Pipe for Refrigeration Devices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

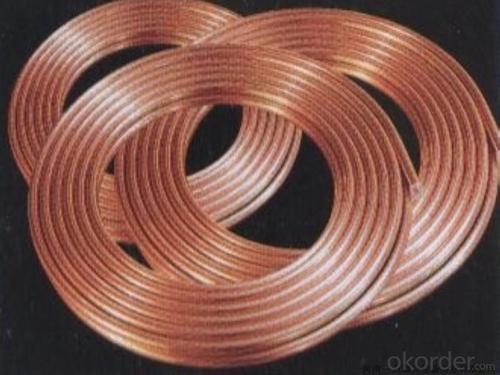

Name:High Performance Refrigeration Copper Pipe for Refrigerating

| Model: | P2、TU1、TU2、T2 |

| Brief: | Mainly used in refrigerating system of air conditioners; high precision and pressure-resistant product manufactured through extrusion, rolling, drawing, surface treatment, and heat treatment, usually processed into finned refrigeration pipe and other refrigeration devices. |

Type Specificationss:

Item | air conditioner copper pipe |

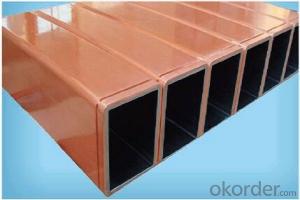

Type | straight copper pipe,pancake coil copper pipe,capillary copper pipe |

Standard | GB/T1527-2006,JIS H3300-2006,ASTM B75M,ASTMB42,ASTMB111,ASTMB395, ASTM B359,ASTM B188,ASTM B698,ASTM B640,etc |

Material | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920, C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300, C12500,C14200,C14420,C14500,C14510,C14520,C14530,C17200,C19200, C21000,C23000,C26000,C27000,C27400,C28000,C33000,C33200,C37000, C44300,C44400,C44500,C60800,C63020,C65500,C68700,C70400,C70620, C71000,C71500,C71520,C71640,C72200,etc |

Shape | Round,Square,Rectangular,Oval,half-round |

Outside diameter | 4.76-28.58mm |

Wall thickness | 0.4-1.5mm |

Length | 1m,2m,3m,6m,or as required |

Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard,soft,. |

Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required |

Price Term | Ex-Work,FOB,CNF,CFR,CIF etc |

Payment Terms | TT,L/C etc |

Export to | Singapore,Indonesia,Ukraine,Korea,Thailand,Viet Nam,Saudi Arabia,Brazil,Spain,Canada, USA,Egypt,Iran,India,Kuwait,Dubai,Oman,Kuwait,Peru,Mexico,Iraq,Russia,Malaysia,etc |

MOQ | 2 tons |

Package | Standard export package ,or as required. |

Application | Copper pipe have strong, corrosion resistant properties, and become a modern contractor in all of commodity house pipes, heating, cooling water piping installation of choice |

Contact | If you have any question ,please feel free to contact me we are sure your inquiry or requirements will get prompt attention |

Usage: Mainly used in refrigerating system of air conditioners; high precision and pressure-resistant product manufactured through extrusion, rolling, drawing, surface treatment, and heat treatment, usually processed into finned refrigeration pipe and other refrigeration devices.

Production Equipment

750-1500kg main frequency induction copper melting furnace, 80MN water seal extruder, LG60 high speed two-roll cold pilger mill, straight-line wire-drawing machine, copper tube/pipe straightener, polisher, 84′ copper coil winding machine, straightening-cutting & pancake coiling machine, thermoplastic packaging machine, 1.2T continuous bright annealing furnace.

80MN extruder

Continuous bright annealing furnace

Testing Devices

spectrum analyzer, atomic absorption analyzer, spectrophotometry, analytical balances, metallurgical microscope, eddy current flaw detector, metal tensile testing machine, eddy conductivity instrument.

Hardness tester

Spectrum analyzer

Metallurgical microscope

Metal tensile testing machine

Atomic absorption analyzer

Process

refined copper — smelting & casting — extrusion — rolling — drawing — straightening-cutting/forming of pancake coil — bright annealing — packaging — finished goods.

Standards

GB/T 1527-2006 Drawn tube of copper and copper alloys

GB/T 16866-2006 Dimensions and tolerances of copper and copper alloy seamless tubes

GB/T 4423-2007 Copper and copper-alloy cold-drawn rod and bar

GB/T 5231-2001 Wrought copper and copper alloys chemical composition limits and forms of wrought products

GB/T 5585.1-2005 Copper or aluminium and its alloy bus bars for electrical purposes—Part 1:Copper andcopper alloy bus bars

GB/T 17791-2007 Seamless copper tube for air conditioner and refrigeration equipment

GB/T 19850-2005 The seamless round copper tubes for electrical purposes

GB/T 26024-2010 Seamless copper and copper alloys tube for valves on air-conditioning and refrigeration system

ASTM B280-2008 Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

EN 12735-1:2001 Copper and copper alloys Seamless,round copper tubes for air-conditioning and refrigeration Part 1:Tubes for piping systems

EN 12735-2:2001 Copper and copper alloy – seamless round copper tube/pipe for air-conditioning and refrigeration system – for equipment

JIS H3300-2009 Seamless copper and copper alloy tube/pipe

- Q: Is there any way to go from 1/2 copper pipe to 1/2 PVC and CPVC without having to sweat the fitting?I am replumbing my kitchen and I need to go from the existing 1/2 hot and cold water pipes which are copper to a down run made of pvc and cpvc.I need to know how to fit the copper to the plastic without sweatting a fitting to the copper.Are there pressure fittings for copper pipe like there is for tubing?

- I own a Construction Co and have seen this issue several times with copper. If you do nothing you will no doubt be repairing it again - not to mention high water bills, water damage to wood and other things. You may use CPVC which is rated for both hot and cold water. You may also use PVC which is rated only for cold water - or your both (required for Commercial). Id bit the bullet and replace all the copper. Remember 3/4 mainline split down to 1/2 for each fixture which will usally go down to 3/8. This way more than likely you wont have any water pressure issues. Wrong size line can cause variances

- Q: How long can not be longer than the longest one? Thank you

- Generally speaking, 3M standard configuration, the longest not more than 10M, but the effect is worse, in the middle of cold consumption, in fact, you can add more cold media can also. It just depends.

- Q: My family is going to install an air conditioner cabinet 3P living room, living room about 35 square, but copper should at least ten meters, not more than ten meters of this brass, have little impact on the effect of air conditioning, if installed air conditioning effect is just a little bit, with no what meaning, or my apartment layout ventilation effect quite good, and the living room cabinet household should also rarely, we can talk about the brass ten meters, have much impact on the air conditioner? Like my family this phenomenon, we can give an opinion ah!

- Every time we question the longest bobbin how long do you know? Frighten you 35 meters!! The effect of 5 horses did not drop anything! As long as you can add appropriate fluoride this 10 meters completely. I'm sure!

- Q: Which kind of copper pipes would used in water construction?I want to the pipe size (diameter and thickness) ,the standard and the grade.If you can help me it will be so nice.

- Copper okorder

- Q: seems to be coming from the T connection from dishwasher

- flying dragon is quite correct in his answers. In addition Mg+2 is a co-factor in over 50 enzymatic reactions in the body and is involved in all reactions involving phosphate transfer( hydrolysis of ATP, pyrophosphatase, etc )

- Q: When we did a lab in chemistry class, we took 6.95 g Copper (ll) Sulfate and added 85.11 g of water, then heated the solution up for about 2 minutes. We then took it off the heat and added 10 g of iron filings. We then let the mixture sit over night and we came back to it the next day when we had class. We filtered out the liquid, and we were left with the solids, which should have been copper and iron. But when we took the magnet to the solids, there was iron and only iron, no copper whatsoever on the filter paper or even on the iron filings like there should have been. What happened to the copper? did the reaction not take place?Please list any sources if you have any, so I can continue my research :)

- Check the color of the solution containing copper (II) sulfate. Is it still bluish? If it is, then there might have been no reaction. If there had been reaction, the solution would turn less bluish or completely colorless. Was the iron filings used still fresh? (Was it taken from a very old stock of iron filings?) If it is not, maybe the iron filings has already been oxidized. The oxide will not react with copper sulfate unless the solution is acidic. Or maybe, the reaction was incomplete so there was still iron filings left, mixed along with the copper metal when the solution was filtered. Check if there is some reddish-brown specks or particles in the filtered solid, it might be copper.

- Q: I live in ontario near toronto if that helps any and i cant find the price of copper. Dirty and/or clean prefer to know both. thank you

- The copper price is quoted in London, USA,China and India. Since Canada is the third largest producer in the world after Chile and the US, the price of copper in Canada will follow the international price. For example it was quoted $3.9594 on 10Nov.2010. Check it out.

- Q: Could someone please tell me the:Refractive index for Copper Bismuth Sulphide. I guess the formula is: CuBiS2

- Refractive index is a ratio of speeds of light in different media. It seems pointless to talk about speed of light in copper, but there is still a refractive index. It can be found by Brewster's Law. In short, light reflected off surfaces is partially polarized. The degree of polarization increases as the angle between the light and the surface reaches 0. The angle at which complete polarization occurs tells you the refractive index of the material.

Send your message to us

High Performance Refrigeration Copper Pipe for Refrigeration Devices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords