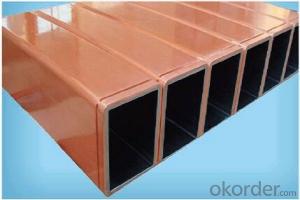

High Density High Purity Copper Alloy Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: High Density High Purity Copper Alloy Bar

Type Specifications: T2, TU1, TU2, TP2

Produced by low-vacuum copper smelting casting technology with its intellectual property right owned by Feichi Copper & Aluminum; high density and high purity product with low hydrogen and oxygen content, usually processed into copper products of various shapes and widely applied in steelmaking, electric power, shipbuilding, and machinery sectors

Application:

Produced by low-vacuum copper smelting casting technology with its intellectual property right; high density and high purity product with low hydrogen and oxygen content, usually processed into copper products of various shapes and widely applied in steelmaking, electric power, shipbuilding, and machinery sectors

Special Shaped tungsten products

We produce special shaped tungsten products and other OEM products.

Production Equipment

750-1500kg main frequency induction copper melting furnace, 80MN water seal extruder, LG60 high speed two-roll cold pilger mill, straight-line wire-drawing machine, copper tube/pipe straightener, polisher, 84′ copper coil winding machine, straightening-cutting & pancake coiling machine, thermoplastic packaging machine, 1.2T continuous bright annealing furnace.

80MN extruder

Continuous bright annealing furnace

Testing Devices

spectrum analyzer, atomic absorption analyzer, spectrophotometry, analytical balances, metallurgical microscope, eddy current flaw detector, metal tensile testing machine, eddy conductivity instrument.

Hardness tester

Spectrum analyzer

Metallurgical microscope

Metal tensile testing machine

Atomic absorption analyzer

Process

refined copper — smelting & casting — extrusion — rolling — drawing — straightening-cutting/forming of pancake coil — bright annealing — packaging — finished goods.

Standards

GB/T 1527-2006 Drawn tube of copper and copper alloys

GB/T 16866-2006 Dimensions and tolerances of copper and copper alloy seamless tubes

GB/T 4423-2007 Copper and copper-alloy cold-drawn rod and bar

GB/T 5231-2001 Wrought copper and copper alloys chemical composition limits and forms of wrought products

GB/T 5585.1-2005 Copper or aluminium and its alloy bus bars for electrical purposes—Part 1:Copper andcopper alloy bus bars

GB/T 17791-2007 Seamless copper tube for air conditioner and refrigeration equipment

GB/T 19850-2005 The seamless round copper tubes for electrical purposes

GB/T 26024-2010 Seamless copper and copper alloys tube for valves on air-conditioning and refrigeration system

ASTM B280-2008 Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

EN 12735-1:2001 Copper and copper alloys Seamless,round copper tubes for air-conditioning and refrigeration Part 1:Tubes for piping systems

EN 12735-2:2001 Copper and copper alloy – seamless round copper tube/pipe for air-conditioning and refrigeration system – for equipment

JIS H3300-2009 Seamless copper and copper alloy tube/pipe

- Q: i want to know how much the wall thickness of a 1/4, 3/8, 1/2, 5/8 copper pipe for air conditioning.

- it is measured in gauge and is usually 20 gauge.

- Q: I'm a bit confused is this the formula for Copper III Tartrate: Cu2 (C4H4O6)3OR is it Cu(C4H4O6)3And if it is the second one then why is it that one?Also, Why is Zinc Phosphate's formula Zn3(PO4)2 and not Zn3PO4

- I'm half certain that the first one is the correct formula. Compounds must balance each other out ionically to be stable so you have to bear in mind the valency of each half. Copper ions have a valency of +3 and Tartrates have a valency of -2. To make the ionic formulae balance you need 2 Copper ions to bond giving you +6 and therefore 3 Tartrate ions to bond giving -6. This way they balance out and you have the stable formula Cu2 (C4H4O6)3. The answer to your second question is much the same. The valency of (Zn) ion is 2 and that of Phosphate is -3. The valencies are balanced by using 3 (Zn) and 2 Phosphate i.e. Zn3 PO4(2)

- Q: If I strip all the copper piping from an average one story house, how much money on average can i get for it at a metal scrap yard.

- Yes you can, find a local recycling scrap yard in your area. The amount of money you are paid depends on the grade of the copper, copper pipes will bring a little less than copper wiring. Take the plastic sheath off of the wiring first, it's best to do this with a razor blade laying the wire on a board being extremely careful! I would not suggest burning it. That is a fast way yes, but it degrades the copper and makes it less valuable. My husband just bought several spools of wire at a garage sell for 10 bucks, spent a week stripping it in his spare time and just sold it to the recycling center fot 173 bucks. Not bad.

- Q: I think taurus makes a solid copper hand gun bullet and maybe one or two other companies do as well. The reviews are great.

- Why are they needed, a copper jacket is all that is required. Sounds like a good sales pitch.

- Q: A piece of copper metal (specific heat 0.385J/g degree C ) at 86.5degree C is placed in 50.0g of water at 16.4 degree C. The metal and water come to the same temperature of 23.9 degreeC

- Hello ssssss, your question comes under the category of physics, but still its a simple one. Here's how to solve it: We know that, In thermal equilibrium, Heat lost by a hot body equals heat gained by a cold body. Here, the hot body is the piece of copper, since is temperature is higher as compared to water. The common temperature 't' attained by both is 23.9 degrees C. So, Let m(copper) be the mass of copper. So we have the following parameters: t = 23.9 degrees C m(copper) = ? c(copper) = .385 J/g degrees C t(copper) = 86.5 degrees C m(water) = 50g c(water) = 4.2 J/g degrees C t(water) = 16.4 degrees C So, heat lost by hot copper metal = heat gained by cold water. m(copper) x c(copper) x ( t(copper) - t ) = m(water) x c(water) x ( t - t(water) ) m(copper) x 24.101 = 1575 Or, m(copper) = 1575/24.101 m(copper) = 65.34999 g = 65.35 g Wasn't it simple! Hope my steps were clear to you By W@W.

- Q: I'm trying to install a new dishwasher but the pipe fitting used to feed hot water to the new machine is a 1/2-in while my old one used a 3/8-in pipe. Home depot said there was No adapter and my only choice was to spend 80 bucks on new copper tubing but I want a second opinion.

- You do not indicate the sizes of the piping in question, nor what the rating was for the PVC pipe initially installed. This may have some bearing on the method of repair because copper is now very expensive and SCH 40 copper pipe would be both difficult to find and exceptionally expensive if you did. Also, copper is already an extravagant material to use on chilled water piping (not small tubing) when flanged and welded Sch 40 carbon steel is the most commonly used material in larger sizes and screwed galvanized pipe is used for most 2 1/2 and smaller. PCV pipe needs to be supported more frequently than steel pipe and will have a much lower service pressure rating. However, your operating pressure may still be within the allowable range. At these service temperatures, thermal expansion is not going to be a problem regardless of what materials are used. If your ONLY problem is that some joints leak, it is probably because the surfaces were not proplerly prepared and/or the cement was not allowed adequate time to set before the piping was moved around. I would recommend that in this case you forget the copper ( forever) and investigate the cutting-out and proper replacement of the several deffective fittings with CPVC Sch 40, piping and equivalent solvent joint fittings.

- Q: I need to know how to turn copper green fast!! Any ideas? If so tell me about how long it will take!!!!

- By using dil. sulphuric acid. (brush it on or something)..It will form copper sulfate, the aqua blue tint seen on old copper. (use adult supervision if necessary).Brush the solution on and wait a few moments for results. To stop the coloration, rinse the acid off with a lot of fresh running water. ****if u are preparing the Dil. sulphuric acid, ALWAYS ADD THE ACID TO THE WATER WITH STIRRING... NEVER ADD WATER TO CONCENTRATED ACID [it could explode in your face]. *just to add to the note and to clarify to in_loora.. You are right but Oxidation is also referred to the charge that an atom would have on a whole...please refer to the second link on my sources...and this is the reaction we are talkin abt wen say oxidation of copper.

- Q: I replaced the faucet in my bathroom and I was wondering if I should take the copper pipes off of the old faucet before I throw it out, there are 4 pipes, 3 of them are about 11 or 12 inches long and one is about 6 or 7 inches long.

- Copper like gold is wroth money! Save it up and sell it! Aluminium is also wroth money.

- Q: I‘ve done a lot of electrical work around my house, but I‘ve never done any plumbing before. The guy at Home Depot told me that I need to heat the fitting, but not the pipe itself. He also said that valves (the new ballcock type) are easily destroyed by overheating. How do I know when the pipe and fitting is ready to accept the solder? How do I avoid damaging the valve? How do I know how strong to turn up the flame on the propane torch?

- It can be kinda tricky, but I learned how to do it so you can too. If the copper fittings aren't brand new, be sure and use some steel wool or find sand paper to shine up the copper and remove any dirt or coatings/corrosion. Dry-fit everything first to make sure it's going to fit correctly -- then take apart and brush plenty of flux on all the copper surfaces that will be receiving solder. In electrical work, the flux is built-into the solder, but not in plumbing. Then, get the torch very hot so you can heat the copper quickly. Heating quickly is better than slow heating, as there's less time for the heat to transfer to the valves, etc. When the copper is hot enough, the solder will flow. It won't take much solder. Test for leaks after it cools. Watch demonstrations of this on YT and on some of the DIY websites like This Old House, etc.

- Q: best way to seal off an open water pipe?

- You can either put a valve there and shut it off, or just solder an end cap to the pipe. They're made for every size of copper tubing. Yours is probably 1/2 inch.

Send your message to us

High Density High Purity Copper Alloy Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords