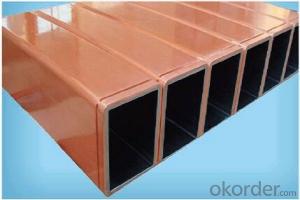

Oxygen-free Copper with High Conductivity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: Oxygen-free Copper with High Conductivity

Type Specifications: T2, TU1, TU2, TAg

Copper busbar is a strip or bar of copper that conducts electricity, often produced with high purity oxygen-free copper ingot through extrusion and drawing processes, usually used in high and low voltage electrical equipment, switch contact, electrical distribution equipment, and bus slot, etc.

Oxygen-free copper busbar and copper bar with high conductivity Specifications

Type | Cu%(WT) | W%(WT) | RWMA | Density | E-conductivity(Min) | heat conduction | thermal expensivity | |

Class | (Min) | Hardness | ((W/mK)) | |||||

(Min) | ||||||||

CuW55 | 45±2 | Balance | 10 | 12.30g/cm3 | 49%IACS | 125HB | ~260 | ~11.7(10-6/K) |

CuW60 | 40±2 | Balance | 12.75g/cm3 | 47%IACS | 140HB | |||

CuW65 | 35±2 | Balance | 3.30g/cm3 | 44%IACS | 155HB | |||

CuW70 | 30±2 | Balance | 13.80g/cm3 | 42%IACS | 175HB | ~240 | ~9.7(10-6/K) | |

CuW75 | 25±2 | Balance | 11 | 14.50g/cm3 | 38%IACS | 195HB | 200~230 | 9.0~9.5 (10-6/K) |

CuW80 | 20±2 | Balance | 12 | 15.15g/cm3 | 34%IACS | 220HB | 190~210 | 8.0~8.5 (10-6/K) |

CuW85 | 15±2 | Balance | 15.90g/cm3 | 30%IACS | 240HB | 180~200 | 7.0~7.5(10-6/K) |

Application: Copper busbar is a strip or bar of copper that conducts electricity, often produced with high purity oxygen-free copper ingot through extrusion and drawing processes, usually used in high and low voltage electrical equipment, switch contact, electrical distribution equipment, and bus slot, etc.

Production Equipment

750-1500kg main frequency induction copper melting furnace, 80MN water seal extruder, LG60 high speed two-roll cold pilger mill, straight-line wire-drawing machine, copper tube/pipe straightener, polisher, 84′ copper coil winding machine, straightening-cutting & pancake coiling machine, thermoplastic packaging machine, 1.2T continuous bright annealing furnace.

Testing Devices

spectrum analyzer, atomic absorption analyzer, spectrophotometry, analytical balances, metallurgical microscope, eddy current flaw detector, metal tensile testing machine, eddy conductivity instrument.

Process

refined copper — smelting & casting — extrusion — rolling — drawing — straightening-cutting/forming of pancake coil — bright annealing — packaging — finished goods.

Standards

GB/T 1527-2006 Drawn tube of copper and copper alloys

GB/T 16866-2006 Dimensions and tolerances of copper and copper alloy seamless tubes

GB/T 4423-2007 Copper and copper-alloy cold-drawn rod and bar

GB/T 5231-2001 Wrought copper and copper alloys chemical composition limits and forms of wrought products

GB/T 5585.1-2005 Copper or aluminium and its alloy bus bars for electrical purposes—Part 1:Copper andcopper alloy bus bars

GB/T 17791-2007 Seamless copper tube for air conditioner and refrigeration equipment

GB/T 19850-2005 The seamless round copper tubes for electrical purposes

GB/T 26024-2010 Seamless copper and copper alloys tube for valves on air-conditioning and refrigeration system

ASTM B280-2008 Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

EN 12735-1:2001 Copper and copper alloys Seamless,round copper tubes for air-conditioning and refrigeration Part 1:Tubes for piping systems

EN 12735-2:2001 Copper and copper alloy – seamless round copper tube/pipe for air-conditioning and refrigeration system – for equipment

JIS H3300-2009 Seamless copper and copper alloy tube/pipe

- Q: Air conditioning outside a copper pipe with water droplets, only with no water drops, how is it?

- Compared with the size of two copper connecting pipe, called coarse low-pressure pipe, called high-pressure pipe fine, is connected inside and outside the machine, the inner and outer machine to form a closed system, the refrigerant can flow across the inner and outer machine, cooling case pipe go gaseous refrigerant, go tubular liquid refrigerant (air and cold exposed brass contacts forming beads)The refrigerant of an outdoor unit and an indoor unit is exchanged by connecting copper tubes, and if the insulated sponge is damaged, the refrigerating efficiency is greatly reduced, and the power consumption is increased

- Q: Defects in copper tubes

- At present, the domestic well-known copper pipe manufacturer's Waterway reconstruction cost is all inclusive, the price is 4, in charge of calculates, but at most 70 yuan per meter, in many cases are more than 50 meters per meter, so it is generally acceptable. As for some people say that copper tube cooling fast, the general manufacturers will pay attention to this problem, will guarantee the insulation of copper tubes, such as plastic insulation film.

- Q: A reaction between sulfur and copper powder produce:Cu2S orCuS

- it depends on whether you are starting with Cu(I) or Cu(II) if it is Cu(I) then Cu2S if it is Cu(II) then CuS

- Q: i need to to copy a picture on a copper. i used the papers that are called i think "Carbon " but it didn't work. i was wondering if there is any other type of papers that i can use to copy the pictures on a copper.Thanks

- you could use the blue ink paper that you can put on your copper and draw on top as this transfer the drawing on to the surfice The Paper is Called 'CARBON PAPER'

- Q: Can you tell me anything about copper and the environment. Like pollution and how it affects the air, water and soil. Just anything. Thanks!

- Copper is poisonous so, if you have copper compounds that are water soluble, too much will kill fish and plants. Some uber-aquarium afictionadoes intentionally add just enough copper compound to their aquariums to keep the algea from growing but not too much to kill their fish.

- Q: Copper slag uses.

- I don't know that slag from copper smelting and processing has any real practical uses. It is simply an industrial waste. Historically, slag has been used as fill when developing sites, and as road base and, somewhat infamously, as railroad ballast (the base for the railroad). Slag is a very important source of soil contamination in some areas (such as the city where I live). Slag is associated with leachable (potentially mobile) heavy metal contamination and contamination by complex organic molecules (polycyclic aromatic hydrocarbons or PAHs). I do know that some slag wastes and foundery sands are used in the preparation of paving aggregate (road tar), but the materials have to meet relatively strict leach characteristics, at least where I live. For the most part these days, slag is treated as a waste and either impounded with mine tailings or placed into secure landfills. At least, that is my experience where I live.

- Q: I have a ton of pennies laying around and have started sorting and organizing them.Is it true that pre-1982 pennies were real copper, while post-1982 pennies are not? So if there were a ton of pre-1982 pennies, could they be cashed in for the value of the copper as well as the monetary?

- It's true that pre-1982 cents are 95% copper (with a current metal value of 2.44 cents each) and that post-1982 cents have only a thin layer of copper plating over zinc (with a current metal value of a little over 1/2 cent each). But, what about the 1982 cents that you've skipped over? You will find both kinds dated 1982. The Mint made the switch during the production year. There are two ways to tell the difference. The best way is with an accurate metric scale. Copper cents will weigh just over 3 grams, the zinc around 2.5 grams. I don't have such a scale, but I've gotten the 'drop' test nailed down. Drop the coin on a hard tabletop and if it makes a 'ring' it's copper, if it's a dull sound, it's zinc. To double-check, drop a pre-'82 and post-'82 and compare. People cash in their pennies for more than face value all the time. There atre copper bullion buyers just as there are buyers of precious metals. They're harder to find, but they're out there. You can get from 1.5 to 2 cents each for large quantities. There are roughly 145 cents to a pound. Buyers go by the poundage, not the number of coins. They might go as high as $2.90 a pound right now with copper at $3.70, but I would expect something in the $2.25 - $2.50 range per pound.

- Q: What instruments do you have in a brass tube?

- Tuba (Tuba)The tuba is the largest bass brass instrument in the orchestra. It has a deep, deep and dignified tone, and is the basis of orchestra and Sonata, as well as double bass. The structure is composed of three parts: mouth, pipe body and machinery. There are four to six pistons (Rotary is more common). A hug Tuba tuba, ring type large and large transit (commonly known as "Su Safeng") three, after only two for the band or orchestra.There are many large shapes, in addition to holding type, ring type, Su Safeng mentioned earlier, there is an excellent California (Tenor tuba). The orchestra also uses G, F, and C for tuba. Large in a band, mainly bass, harmonic, or rhythmic, rarely used in solos. In fact, it not only large bass, treble is also very beautiful, so modern composers occasionally Tuba playing the melody, such as Ravel's orchestration of "pictures at an exhibition" in the "ox" theme, is playing with a large.

- Q: Is it safe to put a copper gas pipe on the outside of your house?

- NO copper is to soft, use Black Pipe do not use Galvanized Pipe as the gas could leach out

Send your message to us

Oxygen-free Copper with High Conductivity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords