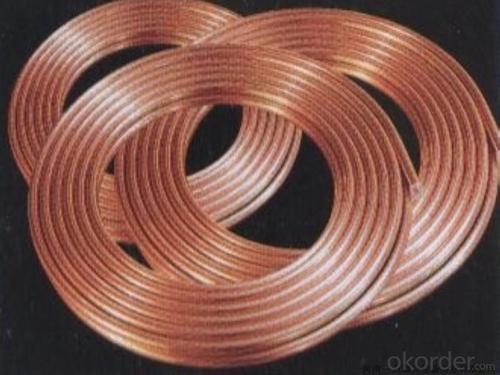

Refrigeration Copper Pipe for Finned Refrigeration Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Name:Refrigeration Copper Pipe for Finned Refrigeration Pipe

| Model: | P2、TU1、TU2、T2 |

| Brief: | Mainly used in refrigerating system of air conditioners; high precision and pressure-resistant product manufactured through extrusion, rolling, drawing, surface treatment, and heat treatment, usually processed into finned refrigeration pipe and other refrigeration devices. |

Type Specifications:

Item | air conditioner copper pipe |

Type | straight copper pipe,pancake coil copper pipe,capillary copper pipe |

Standard | GB/T1527-2006,JIS H3300-2006,ASTM B75M,ASTMB42,ASTMB111,ASTMB395, ASTM B359,ASTM B188,ASTM B698,ASTM B640,etc |

Material | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920, C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300, C12500,C14200,C14420,C14500,C14510,C14520,C14530,C17200,C19200, C21000,C23000,C26000,C27000,C27400,C28000,C33000,C33200,C37000, C44300,C44400,C44500,C60800,C63020,C65500,C68700,C70400,C70620, C71000,C71500,C71520,C71640,C72200,etc |

Shape | Round,Square,Rectangular,Oval,half-round |

Outside diameter | 4.76-28.58mm |

Wall thickness | 0.4-1.5mm |

Length | 1m,2m,3m,6m,or as required |

Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard,soft,. |

Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required |

Price Term | Ex-Work,FOB,CNF,CFR,CIF etc |

Payment Terms | TT,L/C etc |

Export to | Singapore,Indonesia,Ukraine,Korea,Thailand,Viet Nam,Saudi Arabia,Brazil,Spain,Canada, USA,Egypt,Iran,India,Kuwait,Dubai,Oman,Kuwait,Peru,Mexico,Iraq,Russia,Malaysia,etc |

MOQ | 2 tons |

Package | Standard export package ,or as required. |

Application | Copper pipe have strong, corrosion resistant properties, and become a modern contractor in all of commodity house pipes, heating, cooling water piping installation of choice |

Contact | If you have any question ,please feel free to contact me we are sure your inquiry or requirements will get prompt attention |

Usage: Mainly used in refrigerating system of air conditioners; high precision and pressure-resistant product manufactured through extrusion, rolling, drawing, surface treatment, and heat treatment, usually processed into finned refrigeration pipe and other refrigeration devices.

Production Equipment

750-1500kg main frequency induction copper melting furnace, 80MN water seal extruder, LG60 high speed two-roll cold pilger mill, straight-line wire-drawing machine, copper tube/pipe straightener, polisher, 84′ copper coil winding machine, straightening-cutting & pancake coiling machine, thermoplastic packaging machine, 1.2T continuous bright annealing furnace.

Testing Devices

spectrum analyzer, atomic absorption analyzer, spectrophotometry, analytical balances, metallurgical microscope, eddy current flaw detector, metal tensile testing machine, eddy conductivity instrument.

Process

refined copper — smelting & casting — extrusion — rolling — drawing — straightening-cutting/forming of pancake coil — bright annealing — packaging — finished goods.

Standards

GB/T 1527-2006 Drawn tube of copper and copper alloys

GB/T 16866-2006 Dimensions and tolerances of copper and copper alloy seamless tubes

GB/T 4423-2007 Copper and copper-alloy cold-drawn rod and bar

GB/T 5231-2001 Wrought copper and copper alloys chemical composition limits and forms of wrought products

GB/T 5585.1-2005 Copper or aluminium and its alloy bus bars for electrical purposes—Part 1:Copper andcopper alloy bus bars

GB/T 17791-2007 Seamless copper tube for air conditioner and refrigeration equipment

GB/T 19850-2005 The seamless round copper tubes for electrical purposes

GB/T 26024-2010 Seamless copper and copper alloys tube for valves on air-conditioning and refrigeration system

ASTM B280-2008 Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

EN 12735-1:2001 Copper and copper alloys Seamless,round copper tubes for air-conditioning and refrigeration Part 1:Tubes for piping systems

EN 12735-2:2001 Copper and copper alloy – seamless round copper tube/pipe for air-conditioning and refrigeration system – for equipment

JIS H3300-2009 Seamless copper and copper alloy tube/pipe

- Q: Last year, after 8 years, I had the first pipe burst that led to the outside faucet. From the looks of it, the previous owners had issues! From the shut off to the faucet there is 8 ft of pipe.and every inch or so, they had a repair. So I replaced the shut off, the 8 foot pipe and the faucet last spring, after it had burst on me. I used the foam wrap insulation from where it enters the house to about 2 feet from the shut off. For the winter, the shut off was in the off position. My outside faucet was opened and I had a cover over the faucet protecting it. I even went along the wall and caulked every little hole I seen around the outside walls to make sure I cut down on drafts. All of this, and I just opened it up 1 hr. ago, and there‘s a hole on the top about 6 inches away from my shutoff. How could this happen with no water in the line?

- Perhaps the shutoff still allows a little water out. freezes at exit and then freezes the rest of the pipe. When I first read your description I thought of all those times I found burst pipes because someone left the hose hooked up and ice ran right in the line. But it sounds like you took the proper precautions. PS after awhile sweating a pipe becomes no Problemo

- Q: im guessing the thickness is standerd.

- I'm sorry but if all you have to work with is about a 15 gallon you may want to seriously consider freshwater rather than saltwater. You know the tank is too small. You need to buy fish that are compatible with your tank size. It's not worth it to set up the tank and keep fish who won't thrive in your care. I don't understand why you want to make things harder on yourself and waste your money. Nano tanks can be kept by experienced aquarists which you are not. If you're not going to spend the time/money, and make the room to care for fish properly, then what's the point?

- Q: I have to replace copper piping with a flex line in order for home depot to be able to install a dishwasher. can anyone walk me thru this? thanks, i need to do this by Tuesday.

- they sell conversion kits at the home depot and Lowe's. all they need are the sizes of the pipes to complete the job. try to get them to use the quick connects, that will make the job go quicker.

- Q: Am wanting to wrap my wood burner with 3/8 soft copper pipe to heat water going to an heat exchanger in my furnace. Will the copper withstand the heat?

- Most alarms work well enough, but my son came up with an interesting twist. He put the siren inside the car, hidden enough that a thief could not spend the time to find it and rip out the wires. When the alarm goes off the inside of the car is filled with siren noise way beyond the threshold of pain and it is hard to loot or steal a car with both hands clamped over the ears. Coupled with an immobilizer it should be pretty effective. He also put a hidden kill switch on the electric fuel pump of his car. The car can be towed away but not driven away. A cheaper but less convenient way to do the same is to remove a critical fuse, like the one for the ECU (fuse #32). The car won't start and it would take a thief too long to figure out why.

- Q: My neighbor has a heating company, the other day i saw him unloading very large amounts of copper pipe from his company truck into cardboard boxes. I am wondering if it is illegal for him to be taking that much pipe from his work sites? I wan't to make sure i am not jumping to conclusions about my neighbor. Thanxx

- First of all the guy's has a heating company. Copper pipe is like one of the biggest materials! That alone should make you quit wondering and being nosey. But, let me explain. When companies like home heating companies do projects they commonly connect piping. That piping can be steel but very often it is copper. Part of the project requires they demo old piping such that they can put in the new piping. The quantity of demo'd piping can be alot or not so much. If they are busy you can imagine there may be a significant quantity of scrap. Now when the project is over they naturally have to clean up and make the site nice and clean. Well that scrap and dirt and dust and stuff must be cleaned up. It would be unprofessional if they didn't. Well copper pipe has value so what do you think? They are going to throw the copper out and let the garbage man get the money? Look, if you do a project and there is scrap you can tell the contractor not to take it away. He won't. But if you say nothing, then he is expected to police the area and leave it as a professional will. Looking good. All the scrap and crrapp hauled off. Don't worry about it. Oh if you see your neighbor hauling out a rolled up carpet with a nailpolished hand dangling out of it than you might start making conclusions otherwise, forgetaboutit.

- Q: I heard it was from the last one. How much should I use to ask for it?

- The central air conditioning refrigerant pipe does not need to calculate the pipe diameter, and the pipe joint size is limited at the factory equipment joint. Wind system only need to calculate the diameter of the pipe.The wind system is the assumption that the flow velocity range according to GB standards, to assume a wind speed of V, and then through the air as is known, then according to the wind pipe area (3600* = air / wind duct area that is assumed), and then to check the information, the wind pipe what size can be selected, 0.23 is that before the wind area, then you can choose a 500*500 wind pipe, this pipe is 0.25 of the area, then put 0.25 into the formula: = air / wind speed (wind area *3600), namely: V= / air (0.25*3600), can be calculated by 500*500 tube after wind velocity.Finally, the pipe diameter is the diameter of the preliminary design under the premise that the actual flow rate meets the specifications. Of course, the calculation needs to be checked later.Seek acceptance as a satisfactory answer.

- Q: I have lost water pressure in my 1983 home. My pipes are made of copper and I have not had any problems until this morning. I am thinking that one of the pipes has cracked due to the cold temps last night but I just don‘t know where to start! I need some help with troubleshooting before I call a plumber. Can someone please help?For more details.I lose water pressure in the far back bathroom. I have no water filling up the toilet AT ALL. When I turn on the faucet, I lose pressure on the other side of the house. Basically, the further back I go in the house, the less pressure I get. This happen OVERNIGHT. That toilet, by the way, is right next to an outside brick wall where there is an ouside faucet. Thinking there is a link between the two. NO.I did not leave my water dripping last night but I did have insulation on the outside faucet.

- Copper pipes were introduced in the early 80's to replace galvinised pipes which are harmful to health and blocked up faster than copper ones so you had to replace the galvinised ones ever 10 to 20 years so copper was the prefered option .However copper in very cold weather lets all or part of the water inside freeze thus giving you little or no pressure .There could be a blockage depending how clean your water is but highly unlikely As for it leaking it can only leak at joins the copper pipe is what is called annealed copper which means it is reasonably flexible and can be be bent to most shapes around the house without needing heat .If it continues in warm weather get a plumber if not buy some insulation to put around any outside pipes.

- Q: is it harmful to touch copper penny with acid eating it

- If the acid is eating the penny, it is probably fairly strong. If the penny is a US one minted after 1982, it is zinc on the inside, so most strong acids will dissolve this fairly rapidly when the acids are a few M in concentration. These could be corrosive, so I wouldn't touch. If the penny is solid copper (1981 or before) and still being eaten, get out quickly and don't inhale! Nitric acid is the only common acid that can dissolve copper at room temperature (other compound, such as ferric chloride solution, can as well). When nitric acid dissolves a penny, nitrogen oxides (NO and NO2) are released. These gases are very toxic, but exposure causes no symptoms for a few hours. You may feel fine afterwards, but a few hours later, you could die of pulmonary edema.

- Q: i had a copper pipe that blew under my house i cut the part off about 2 to three inches leaving a three inch gap any suggestions on how to fill the gap ??its a 1/2 inch copper pipe for hot water btw

- If use solider ,cut a 1/4 shorter than gap pipe and use two coupling for each sides ,located the cut between cuppings and solider it. If you use brass fitting connection ,use pipe to pipe fitting (it's a two side nipple treaded with nut) ,which pipe will go inside the nut and when you tie the nut ring inside the nut will seal the pipe to fitting .This will be cleaner than do solider job underneath but it take longer .

Send your message to us

Refrigeration Copper Pipe for Finned Refrigeration Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords