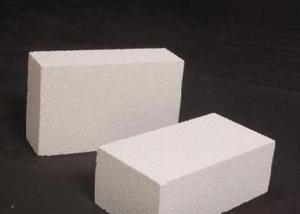

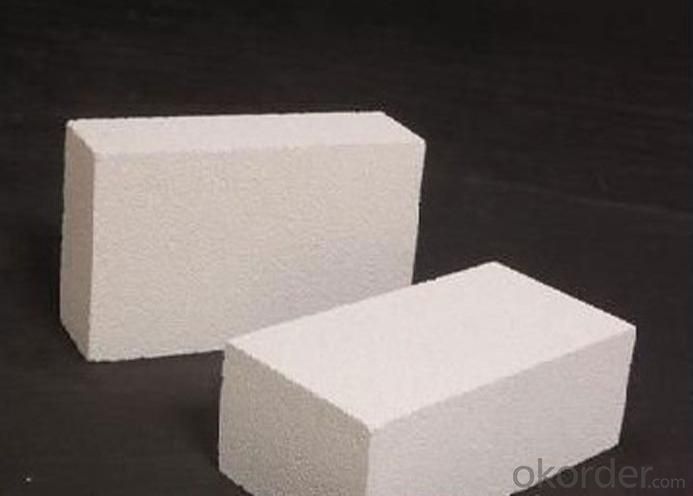

Refractory JM Mullite Insulation Brick in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons m.t.

- Supply Capability:

- 5000 Tons per Month furnace bricks refractory material standard size in stock m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantage of Refractory JM Mullite Insulation Brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Description of Refractory JM Mullite Insulation Brick

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application of Refractory JM Mullite Insulation Brick

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

Sunrise Brand |

JM23 |

JM26 |

JM28 |

JM30 |

JM32 | |

Classification Temperature (°C) |

1260 |

1430 |

1540 |

1650 |

1760 | |

Bulk Density (g/cm3) |

0.55-0.60 |

0.78 |

0.88 |

1.03 |

1.25 | |

Cold Crushing Strength (Mpa) |

1.2 |

1.6 |

2.1 |

2.5 |

3.5 | |

Modulus of Rupture (Mpa) |

0.9 |

1.4 |

1.6 |

2.1 |

2.1 | |

Reheating Linear Change (%)

CT-30 °CX 8H |

1230°C

-0.5 |

1400°C

-0.5 |

1510°C

-0.5 |

1620°C

-0.9 |

1730°C

-0.9 | |

Thermal Expansion

1000°C(%) |

0.5 |

0.7 |

0.8 |

0.9 |

1.1 | |

Thermal conductivity(W/m.k) |

400°C |

0.14 |

0.27 |

0.32 |

0.41 |

0.49 |

600°C |

0.16 |

0.29 |

0.34 |

0.43 |

0.5 | |

800°C |

0.18 |

0.31 |

0.36 |

0.44 |

0.51 | |

1000°C |

0.20 |

0.33 |

0.38 |

0.45 |

0.53 | |

Al2O3 (%) |

37 |

58 |

67 |

73 |

77 | |

Fe2O3 (%) |

1.0 |

1.0 |

1.0 |

0.5 |

0.4 | |

- Q: I am buying a home and would like to 'dress up' the back patio area, but don't want to spend a fortune on tile for outdoors...was thinking about staining the front porch and back patio...but I don't know what this would entail...any help? THANKS!

- My bedroom floor is stained concrete. We ripped up the carpet in there, the living room and the front office/living area when we moved into our house. I also stained the back patio to look like terra cotta tiles. I loved my bedroom floor so much that even though we eventually put flooring down in the rest of the house I refuse to even consider it. The color I got at home depot is a sheer golden sun, we used an all purpose sprayer (the 2 gallon kind for bug spray) and then just layered it over the floor. Make sure the floor is clean or you will have a nightmare with dust or dirt residue. Then after you spray it, seal it with a clear cement sealer. You can do patterns, or a solid color, or make it look like stone. I have some very small rugs right by the bed on either side for warmth, but the staining effect looks great!

- Q: I was washing paint brushes in a bucket with water the bucket turned to mostley paint and then the bucket fell on my pation floor which is cement now it wont come off!!!!!!

- Why not just GO FOR IT and paint the rest of the floor?

- Q: will i get crutches from er if i hit my knee cap on the cement step and went to the er or walk in clinic please explain and what if i just go in hopping in on one leg do you think they would give me crutches. do they show you how to use them please explain i want to use crutches

- They will examine you first, and if you don't need crutches, they won't give them to you. It is horrible that you would want to waste everyone's time in the ER simply because you want crutches. While they ER staff are dealing with you, someone who is actually hurt is having to wait a little longer. Go to a medical supply store any buy some crutches if you want them so bad.

- Q: I want to rebuild my porch, It's relatively small.What kind of cement should I purchase.The more info. the better ;)

- First off, you want Concrete, not cement. (Concrete is mostly sand and rock and about 1/6 cement) If you need just a little bit, you can buy this in sacks that you mix with water. If you need more, it's usually brought out in big trucks. Somewhere in-between is getting it in smaller amounts pre-mixed from local rental yards, or trucks that mix it as needed at your house. Do you just need pier posts instead? Those can be bought ready-made. Building forms for concrete and also pouring concrete are skills you should learn on someone else slabs first, don't start here, unless it's all pretty much stuff that doesn't show. It's real easy to do it wrong. I've had forms that blew out, and concrete that set up too fast. It's physically tiring to work with, and has to be done quickly sometimes. Poor concrete work seems to look ugly forever, and the material expense is high, too. I think this is a job worth hiring out. Cost for materials varies locally, concrete in large amounts is sold by the yard. I haven't bought it for awhile, I would guess $100 a yard delivered, but this could be pretty wild. Call some local concrete suppliers for a better guess.

- Q: I would like to close up my a/c for winter. I have the insulation and plastic but do not know how to attach it to my cement walls. Cellophane tape, duct tape, electric tape and masking tape have all proved to fail (and pretty quickly too). Any suggestions from you wonderful Yahoo people? I would be grateful.

- Why do you have to attach it to the cement wall. These products are made to just enclose the unit which is all you need.

- Q: I was wondering if bees can go through cement?Like a cement wall or something.I've heard they can go through wood.

- No bees in my part of the world can go through concrete, or cement or wood, wood is used to make bee hives, (for honey bees) Carpenter bees will chew a hole in some woods (mostly soft woods) I have never seen a Carpenter bee chew a hole in a live or growing tree, The wood generaly has to be cut wood like a park bench or such.

- Q: I unit expansion of production plants, machinery and equipment base, the purchase of steel, cement, building materials, such as the opening of the value-added tax invoices, whether deductible? More

- If the base of the equipment and equipment is included in the value of fixed assets, the input tax on the value-added tax invoice can be deducted.

- Q: Im trying to level my floor with self levelling cement. I know its supposed to be runny but i may have put too much water on it. Unfortunately i already dumped it on the floor. Will it eventually dry up.

- Yes it will dry up just trowel it as smooth as you can and let it set up over night

- Q: Here in the US they use sheet rock and the houses are so flimsy, but in DR they build them so strong and it's 100% cement. Why is that?

- I think the main reason why in the united states houses are not made of cement is because of the price. Is a lot more expensivr to make a cement house rather than other materials. Also depending on where they are being made. In the north houses are made of different materials in order to protect them from the cold. In most of the caribean countries air conditioning is a luxury that only the rich are able to pay, i believe cement houses cool down faster...

- Q: I am putting tile on the wall in my bathroom (not in the shower), do i have to put cement board behind it?or can i just leave the drywall that is already there?

- How To Install Cement Board On Walls

1. Manufacturer Overview

| Location | Luoyang, China (Mainland) |

| Year Established | 2009 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | Eastern Europe; Southeast Asia; Mid East; Eastern Asia; Northern Europe; Southern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory JM Mullite Insulation Brick in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons m.t.

- Supply Capability:

- 5000 Tons per Month furnace bricks refractory material standard size in stock m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords