Encaustic Cement Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters m²

- Supply Capability:

- 5,000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

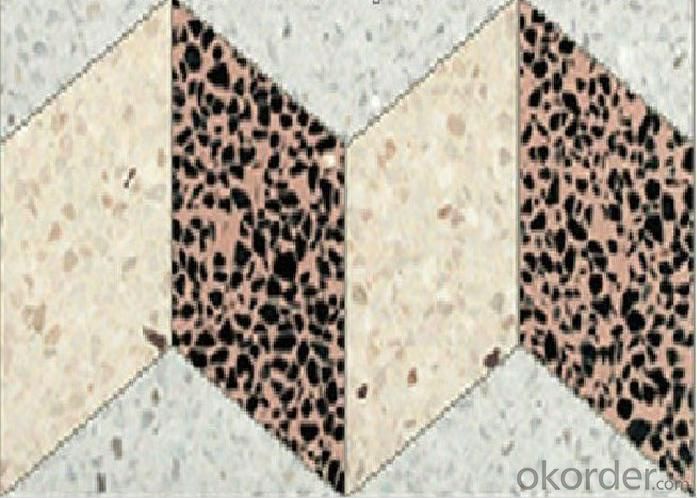

Terrazzo Encaustic Cement Tile

Shock resistance 30 times min

Water Absorption <= 7%

Abrasion +0.45 gr/Cm2

Origin: Vietnam

This is encaustic cement tile, a produce of HANDMADE process created by Skillful Artisant from Vietnam, a country has 100s of Year in making encaustic cement tiles, this production in Vietnam is among the best quality in the world. Inheritating long tradition of making encaustic cement tile together with bring new modern technique to production, our Cement tiles have been produced and controlled under the best conditions to guarantee stable quality for all production batches. Basic material are marble powder and pigment, environmental friendly.

All patterns and Colors can be customized

Available sizes from 50x50mm to 400x400mm which thickness ranging from 12mm till 25mm

Specs:

Length 200mm +/-0.5mm

Width 200mm +/-0.5mm

Height 15mm +/-1.0mm

Top Layer 3mm +/-0.1mm

Technological Parameters:

Weight 1200 gr +/- 50gr

Elasticity 1.200 Newton minimum

Shock resistance 30 times minimum

Water Absorption <= 7%

Abrasion +0.45 gr/Cm2

This is ideal material from indoor using or interior which is suitable for restoration of old building or for luxurious building such as hotels, restaurants, cafe or even for boutique or cottage house.

- Q: I'm trying to install a handrail on a small set of concrete stairs. I drilled/chiseled two 3 inch deep holes for the newel posts. Do I simply put the posts in and add the cement? My fear is that once the cement dries, the cemented newel post quot;plugquot; will not adhere and be able to be pulled out of the hole. Do I have to do anything special to make sure this doesn't happen?

- use a non shrink grout and slope it away from the posts a bit...

- Q: In general which of these three cements creates rocks that are the most resistant to weathering?

- Iron oxide cement will colour the rock a distinctive rusty yellow-brown as a result of the significant presence of the minerals haematite and limonite. Calcite cement will leave the rock white but is soft, easily scratched by an iron nail and will fizz with the application of dilute hydrochloric acid. Silica cement will leave the rock glassy colourless, glassy white or rarely, a different colour but also glassy, it will resist being scratched by an iron nail, and will not react with dilute hydrochloric acid. The rock with the silica cement will be most resistant to weathering, and will normally remain as a positive relief feature around the surrounding rocks. The cement in the calcite cemented rock will tend to become dissolved away. The iron oxide cemented rock will be fairly soft but will resist erosion better than the rock with the calcite cement.

- Q: My basement bathroom is pretty much unfinshed. The shower surround is the bare foundation and the vinyl tiles are just glued to the cement floor. Since its already cement, should I bother installing cement board prior to tiling?Thanks!

- In theory it is, but sometimes the thin-set has a really good bond with the substrate. The hard part is installing the floor tile at the proper and even slope towards the drain. Make sure to use a slip resistant floor tile for the shower. If you use those sheets of 1x1 tiles glued together (Dal-tile) you will have too carefully clean the thinset out of the groutlines before it dries. ( potential big headache) Good luck

- Q: A 20 pound bag of Economy brand cement mix contains 25% cement and 75% sand. How much pure cement must be added to prduce a cement mix that is 40% cement?

- Let x = amount of pure cement (note that pure cement is 100% cement). You are given that 20 = amount of 25% cement. The new mixture (40% cement) will be x+20. Now insert the percentages. (100%)(x) + (25%)(20) = (40%)(x+20) 1x + 5 = 0.4x + 8 Subtract 0.4x from each side 0.6x + 5 = 8 Subtract 5 from each side 0.6x = 3 Divide both sides by 0.6 x = 3/0.6 x = 5 Answer: 5 pounds of pure cement

- Q: What is the good introduction for cement?

- Actually cement is nothing but a normal paste or binder.. there is a setting time of a cement .. time of every cement varies depending on the GYPSUM used. In the most general sense of the word, a cement is a binder, a substance which sets and hardens independently, and can bind other materials together. The word cement traces to the Romans, who used the term opus caementicium to describe masonry which resembled concrete and was made from crushed rock with burnt lime as binder. The volcanic ash and pulverized brick additives which were added to the burnt lime to obtain a hydraulic binder were later referred to as cementum, cimentum, c?ment and cement.

- Q: As in many modern houses, our en-suite shower is made up of tiles fixed onto plaster board. Over the years this has started to leak as the grouting failed, and the plaster board has become soggy and needs replacing. We have had two suggestions from different builders. One suggests ripping out the old plaster board and replacing it with quot;cement boardquot; onto which tiles would be stuck. The other suggestion involves cutting out the old plaster board, replacing it with new plaster board which would then be quot;sealedquot; before tiles are stuck onto it. Does anyone know which of these would be the better option please? Costs of both proposals appear to be similar so we really want the better engineering solution.

- Plasterboard, or drywall, is paper over a gypsum core. Durock, or cement board, is fiberglass mesh over a concrete base. Not only is the cement impervious to water, the rougher surface is a MUCH better base for the tile to adhere to. I would never use anything else under tile.

- Q: If u set a car battery on the ground(dirt,cement,asphalt,etc) will it lose its charge?

- oh yea the concrete will

- Q: I was wondering if anyone out there knew the proper procedure for applying 1.5quot; of asphalt to a soil cement subgrade? I dont know if a tack coat is needed or not. Right now we are planning on a fresh broom finish and a single application of asphalt. Its a low use parking lot but I want to make sure we are doing this right.Thanks!

- we do soil-cement base with AC or HMA surface all the time. Never use a tack coat. The thinking is have a slip plane between the two sections. Tack coat would allow the subbase to telegraph cracks up into the AC. The key is to have the right soil-cement mix at optimal moisture. Too much water will result in shrinkage cracks. With only 1.5 inch AC that could be a problem. How did you come up with a soil-cement mix design? How much cement? how thick in your section? good luck! Don the engineer

- Q: Is there a difference between the two?

- Cement is the binder that holds the ingredients together in concrete. CEMENT: ...a powder of alumina, silica, lime, iron oxide, and magnesium oxide burned together in a kiln and finely pulverized and used as an ingredient of mortar and concrete. CONCRETE: ...a hard strong building material made by mixing a cementing material (as portland cement) and a mineral aggregate (as sand and gravel) with sufficient water to cause the cement to set and bind the entire mass.

1. Manufacturer Overview

| Location | Guangdong,China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia; Domestic Market |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Foshan new port, Shenzhen yantian port, Guangzhou huangpu port |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Arabic, Russian |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Encaustic Cement Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters m²

- Supply Capability:

- 5,000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords