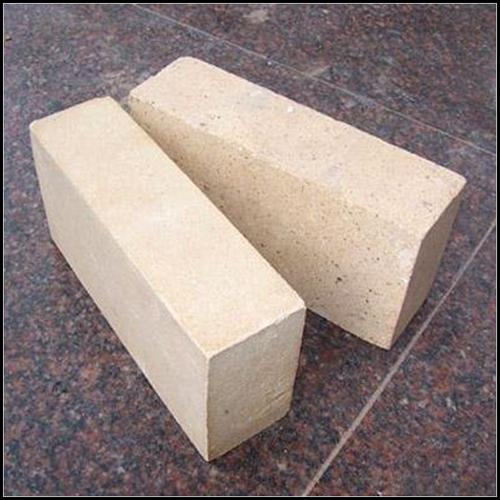

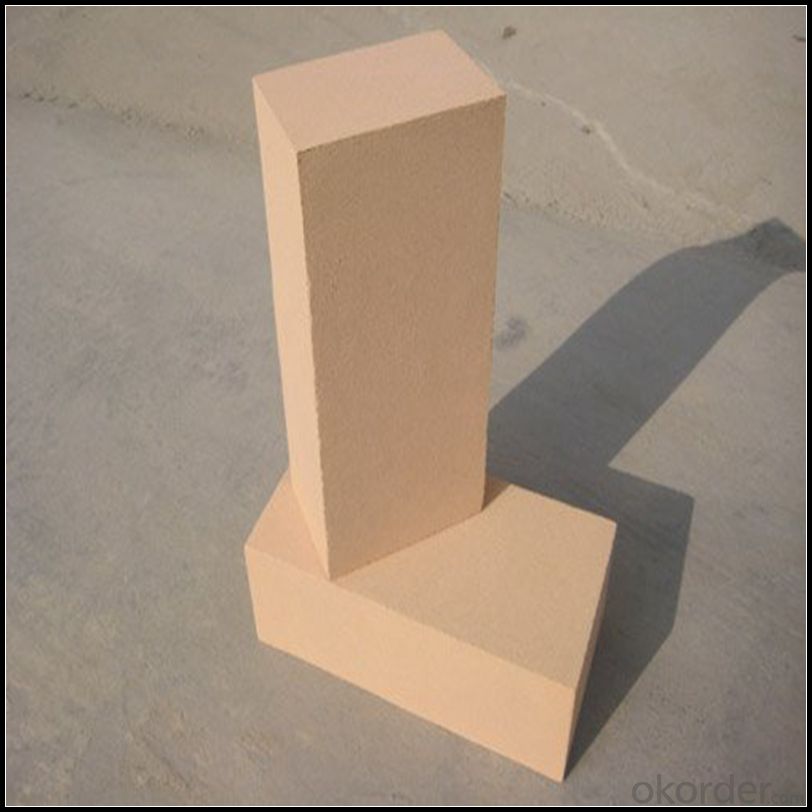

High-Alumina Insulating Fire Brick for Furnace Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Brick

CMAX firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay by mixing, press-forming, drying, sintering and machining. Bricks contain carefully-graded organic fillers which are burned out during sintering to give a uniform controllable pore structure. This technique makes product feature low thermal conductivity and excellent heat insulation

Features

1 Excellent thermal stability2 High refractoriness under load

3 Chemical stability and anti-corrision

4 Small high temperature creep rate

5 Excellent thermal shock resistance

Application

1. Carbon bake furnaces in the aluminum industry

2. Preheat zones and cyclones of rotary cement kilns

3. Insulation for glass tanks

4. Fireplace and pizza ovens

5. Coke ovens

6. Blast furnaces

7. Reheating furnaces

8. Suspended roofs

9. Lime kilns

10. Chimney

Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Are insulating fire bricks resistant to thermal spalling?

- Insulating fire bricks exhibit resistance to thermal spalling, which is the process of a material cracking or fracturing as a result of abrupt fluctuations in temperature or thermal shock. These bricks are specifically engineered to endure elevated temperatures and thermal cycling without spalling. Their low thermal conductivity allows for efficient insulation against heat transfer, thereby reducing the strain caused by thermal expansion and contraction. Moreover, the composition and structure of insulating fire bricks are meticulously designed to offer outstanding protection against thermal spalling, rendering them a dependable option for applications involving intense heat conditions.

- Q: Can insulating fire bricks be used in ceramic fiber blankets?

- It is not possible to use insulating fire bricks in ceramic fiber blankets. Insulating fire bricks are dense and solid, specifically designed to offer insulation and endure high temperatures in settings like furnaces and kilns. Conversely, ceramic fiber blankets are flexible and lightweight, consisting of ceramic fibers that provide exceptional thermal insulation. They are frequently utilized as insulation in diverse industrial applications, such as lining for furnaces, boilers, and high-temperature equipment. Combining insulating fire bricks with ceramic fiber blankets would not yield effective results because these materials possess distinct properties and serve different purposes.

- Q: Can insulating fire bricks be used in the construction of high-temperature reactors?

- Indeed, high-temperature reactors can incorporate insulating fire bricks in their construction. These bricks are explicitly engineered to endure elevated temperatures, rendering them apt for deployment in high-temperature settings like reactors. Their exceptional thermal insulation qualities contribute to minimizing heat loss and upholding the desired temperature within the reactor. Moreover, insulating fire bricks boast remarkable refractoriness, enabling them to endure intense heat without substantial distortion or harm. Hence, they represent an optimal selection for the construction of high-temperature reactors, wherein maintaining a steady and regulated temperature is vital for the reactor's effective operation.

- Q: Are insulating fire bricks resistant to molten metals?

- Yes, insulating fire bricks are generally resistant to molten metals. They are specifically designed to withstand high temperatures and provide insulation, making them suitable for applications involving molten metals.

- Q: Are insulating fire bricks suitable for insulation in walls?

- Yes, insulating fire bricks are suitable for insulation in walls. They are designed to have excellent thermal insulation properties, high heat resistance, and low thermal conductivity. These characteristics make them effective at reducing heat transfer and providing insulation in wall systems.

- Q: Are insulating fire bricks resistant to cracking under pressure?

- Yes, insulating fire bricks are designed to be highly resistant to cracking under pressure. They are specifically manufactured to withstand high temperatures and thermal shocks while maintaining their structural integrity.

- Q: Can insulating fire bricks be used in the construction of hot blast stoves?

- Yes, insulating fire bricks can be used in the construction of hot blast stoves. Insulating fire bricks are designed to have low thermal conductivity, making them effective at reducing heat loss. Hot blast stoves require high temperatures to be maintained for efficient operation, and insulating fire bricks can help in achieving this by minimizing heat transfer to the outer surface of the stove. These bricks also have good insulation properties, which help to conserve energy and improve the overall efficiency of the stove. Additionally, insulating fire bricks are resistant to thermal shock, which is important in hot blast stove applications where frequent temperature fluctuations occur.

- Q: What materials are used for roof insulation?

- There are two kinds: one is a kind of cotton insulation board, such as rock wool board, aluminum silicate cotton board, but this is not environmental protection, harmful to life, foam board (this fire safety factor minimum), these relatively cheap.

- Q: Can insulating fire bricks be used for pizza ovens?

- Yes, insulating fire bricks can be used for pizza ovens. Insulating fire bricks are designed to withstand high temperatures, making them a suitable choice for creating a well-insulated and efficient pizza oven. They help retain heat, allowing the oven to reach and maintain the desired temperature for baking delicious pizzas.

- Q: Can insulating fire bricks be used for insulation in steel mills?

- Insulation in steel mills is possible with the use of insulating fire bricks. These bricks are crafted from lightweight refractory materials that possess exceptional insulating properties and can endure high temperatures. Their purpose is to limit heat transfer and maintain the desired temperature within the furnace or kiln. In the steel mills, these bricks are applicable for insulating the walls, floors, and roofs of the furnaces, ladles, and other equipment. This insulation aids in minimizing heat loss, enhancing energy efficiency, and ensuring consistent and controlled heating processes. Moreover, insulating fire bricks offer thermal stability and safeguard the steel mill equipment against excessive heat, thereby contributing to extended equipment lifespan and reduced maintenance expenses.

Send your message to us

High-Alumina Insulating Fire Brick for Furnace Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords