Recycled Stainless Steel 316 Sheet and Plate for Exporting

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel 316 sheet and plate for exporting

Description of Stainless Steel 316 sheet and plate for exporting:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel 316 sheet and plate for exporting:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Maintance of Stainless Steel 316 sheet and plate for exporting:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Applications of Stainless Steel 316 sheet and plate for exporting:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many applications. There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates, bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipment Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion resistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steamcleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel 316 sheet and plate for exporting:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics of Stainless Steel 316 sheet and plate for exporting:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

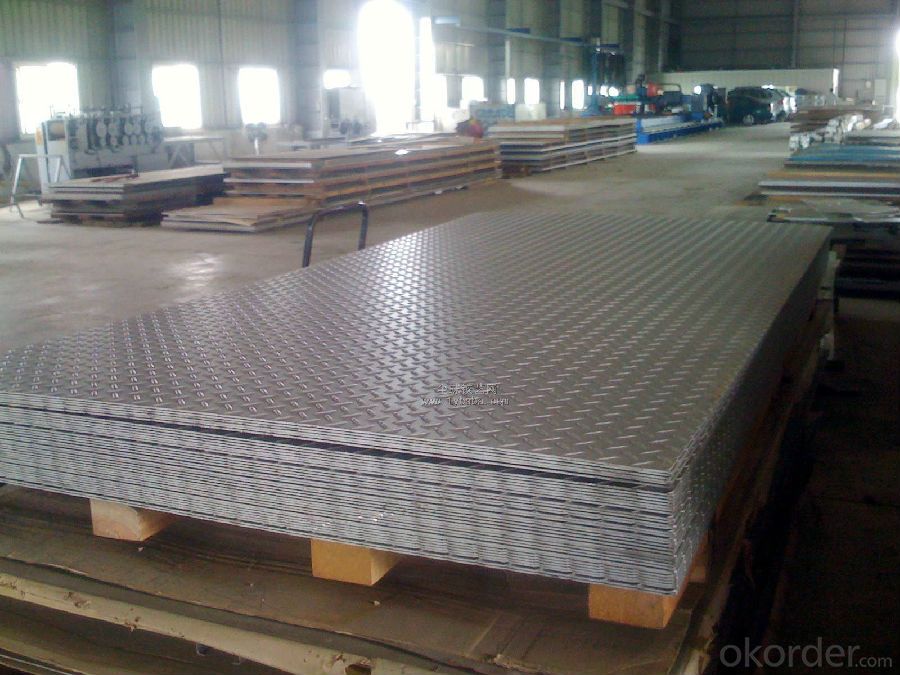

Images of Stainless Steel 316 sheet and plate for exporting:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

Our company adheres to the tenet of "survival by quality, build brand by reputation, win market by prices and innovate to develop", has developed international markets and the products are well sold in many countries as Singapore, Indonesia, South Korea, Dubai, Pakistan, Sri Lanka, Vietnam, Iran, Malaysia, Mexico, Chile, Brazil, Holland, Italy, Belgium, Russia, Moldova, Paraguay, Uruguay, Germany, Spain, USA etc. More than 40 countries.; commonly we have more than 500tons stainless steel materials in stock; so w can arrange the soonest delivery too; also we hope we will have chance to cooperate with your esteemed company!

- Q:What are the different types of colored finishes available for stainless steel sheets?

- There are several different types of colored finishes available for stainless steel sheets. These finishes are designed to enhance the appearance of stainless steel and provide various aesthetic options. Some of the most common colored finishes include: 1. Mirror Finish: This finish is highly reflective and creates a mirror-like surface on stainless steel sheets. It is achieved by polishing the stainless steel surface to a high gloss. Mirror finishes are commonly used in decorative applications and provide a sleek and modern look. 2. Satin Finish: Also known as brushed or matte finish, this type of finish has a smooth, non-reflective surface. It is achieved by brushing the stainless steel surface with an abrasive material. Satin finishes are commonly used in architectural and industrial applications and provide a clean and contemporary appearance. 3. Colored Powder Coating: Powder coating involves applying a dry powder to the stainless steel surface and then curing it under heat. This process creates a durable and uniform colored finish. Colored powder coatings are available in a wide range of hues, allowing for customization and versatility in design. 4. PVD Coating: Physical Vapor Deposition (PVD) is a process that involves depositing a thin layer of metal onto the stainless steel surface. This coating can be in various colors, such as gold, bronze, black, or rose gold. PVD coatings provide excellent durability and resistance to wear, making them suitable for high-traffic areas or decorative applications. 5. Colored Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the stainless steel surface. By using dyes during the anodizing process, a wide range of colors can be achieved. Colored anodized finishes are known for their corrosion resistance and can be utilized in architectural or design-oriented applications. Each of these colored finishes offers unique characteristics and can be chosen based on the desired aesthetic, durability, and specific application requirements. It is important to consider factors such as the level of maintenance needed, environmental conditions, and the intended use of the stainless steel sheets when selecting a colored finish.

- Q:Are stainless steel sheets suitable for cryogenic applications?

- Yes, stainless steel sheets are suitable for cryogenic applications. Stainless steel is known for its excellent mechanical properties, including high strength and toughness, which make it suitable for low-temperature environments. Additionally, stainless steel has good corrosion resistance, which is crucial when exposed to cryogenic temperatures. It maintains its mechanical properties and does not become brittle at ultra-low temperatures. Therefore, stainless steel sheets are commonly used in cryogenic applications such as storage tanks, pipelines, and equipment for liquefied natural gas (LNG), liquid nitrogen, and other cryogenic fluids.

- Q:Stainless steel plate surface treatment: ink, wire drawing, polishing what role?

- Polishing, also known as mirror treatment, no Silk Road, brightness ranging from 4K-12K. By acid water surface grinding, processing costs slightly higher than oil mill and wire drawingI hope I can help you!

- Q:Can stainless steel sheets be used for power generation equipment?

- Yes, stainless steel sheets can be used for power generation equipment. Stainless steel is a versatile material that offers several beneficial properties for power generation applications. It has excellent corrosion resistance, which is crucial in environments where the equipment is exposed to water, steam, or other corrosive substances. Stainless steel also has high strength and durability, making it suitable for withstanding the high temperatures and pressures typically found in power generation systems. Additionally, stainless steel is a good conductor of electricity, making it suitable for electrical components and connections within the equipment. Therefore, stainless steel sheets are commonly used in the construction of power generation equipment such as turbines, boilers, heat exchangers, and exhaust systems.

- Q:How do I prevent stress corrosion cracking on stainless steel sheets?

- To prevent stress corrosion cracking on stainless steel sheets, there are various steps that can be taken: 1. Opt for the appropriate stainless steel grade: Select a stainless steel grade that is resistant to stress corrosion cracking (SCC). Although grades like 304 and 316 generally have good SCC resistance, certain applications may necessitate higher alloyed grades like duplex or super duplex stainless steels. 2. Minimize exposure to corrosive environments: Limit the exposure of stainless steel sheets to environments known to cause stress corrosion cracking, such as chloride-rich or acidic surroundings. If avoiding exposure is not possible, consider applying protective coatings or barriers to shield the stainless steel from these corrosive elements. 3. Manage applied stress levels: Prevent subjecting the stainless steel sheets to excessive mechanical or thermal stresses. High tensile stresses can facilitate the initiation and propagation of stress corrosion cracking. Utilize appropriate design and fabrication techniques to ensure even stress distribution and minimize stress concentrations. 4. Maintain the surface condition: Ensure that the stainless steel sheets are devoid of surface contamination or defects that can serve as initiation sites for stress corrosion cracking. Regularly clean and inspect the sheets to eliminate any contaminants or corrosion products. 5. Employ inhibitors or cathodic protection: In certain cases where exposure to corrosive environments is unavoidable, the use of corrosion inhibitors or the implementation of cathodic protection techniques can help mitigate stress corrosion cracking. These methods work by reducing the corrosive activity on the stainless steel surface. 6. Handle and store properly: Exercise caution during transportation and storage to prevent excessive bending, vibration, or exposure to corrosive substances. Store stainless steel sheets in a clean and dry environment to avoid potential surface contamination. In conclusion, a combination of material selection, environmental control, stress management, surface maintenance, and proper handling can effectively prevent stress corrosion cracking on stainless steel sheets. It is advisable to consult with material experts or engineers to analyze specific application requirements and recommend the most appropriate preventive measures.

- Q:How are stainless steel sheets used in the construction industry?

- Stainless steel sheets are extensively used in the construction industry due to their remarkable properties and versatility. These sheets are mainly utilized for their durability, corrosion resistance, and aesthetic appeal. One of the primary applications of stainless steel sheets in construction is for roofing and cladding purposes. They are commonly used for roof panels, wall panels, and façade systems. Stainless steel sheets provide excellent protection against weather elements, such as rain, snow, and UV rays. They also offer resistance to corrosion, ensuring the longevity of the building's exterior. Additionally, stainless steel sheets are frequently employed in the construction of architectural structures like bridges and tunnels. Their high strength-to-weight ratio makes them suitable for such applications. Stainless steel sheets can withstand heavy loads and provide reliable support, ensuring the structural integrity of these infrastructures. Moreover, stainless steel sheets are utilized in the construction of interior components, such as elevator doors, escalators, and handrails. Their sleek and modern appearance adds a touch of elegance to the overall design. These sheets are also hygienic and easy to clean, making them ideal for applications in hospitals, laboratories, and food processing facilities. In summary, stainless steel sheets play a crucial role in the construction industry. They are used for roofing, cladding, architectural structures, and interior components. With their exceptional durability, corrosion resistance, and aesthetic appeal, stainless steel sheets contribute to the longevity and aesthetic value of various construction projects.

- Q:Can stainless steel sheets be used for wastewater treatment?

- Yes, stainless steel sheets can be used for wastewater treatment. Stainless steel is highly resistant to corrosion and can withstand harsh chemicals and environments, making it an ideal material for wastewater treatment applications. It can be used for constructing tanks, pipes, and other equipment used in the treatment process. Stainless steel sheets are also easy to clean and maintain, reducing the risk of contamination. Additionally, stainless steel is a sustainable material as it can be recycled, making it an environmentally friendly choice for wastewater treatment facilities.

- Q:Can stainless steel sheets be used in food processing or medical applications?

- Yes, stainless steel sheets can be used in food processing and medical applications. Stainless steel is highly resistant to corrosion and is easy to clean, making it suitable for use in environments that require strict hygiene standards such as food processing plants and medical facilities. It is also non-reactive with food and medical substances, ensuring the safety and quality of the products being processed or treated.

- Q:How do you restore the shine on a stainless steel sheet?

- Achieving a polished appearance for a stainless steel sheet can be accomplished by following a few uncomplicated steps. Initially, it is crucial to ensure the cleanliness of the surface by employing a soft cloth or sponge, as well as a mild detergent mixed with warm water, to wipe away any dirt or debris. Subsequently, the soap residue should be rinsed off and the sheet thoroughly dried. Following this, a minute amount of stainless steel cleaner or polish should be applied to a clean, soft cloth. In a circular motion, gently rub the cleaner onto the stainless steel sheet, paying particular attention to areas that exhibit visible marks or dullness. It is important to adhere to the instructions provided by the manufacturer for the specific cleaner or polish being utilized. After the cleaner has been applied, allow it to remain on the surface for several minutes, permitting it to work its magic. Then, utilizing a fresh section of the cloth, buff the stainless steel sheet by employing circular motions until the shine begins to manifest. This process should be continued until satisfaction with the results is achieved. If a specialized stainless steel cleaner or polish is not available, household items can also be utilized to restore the shine. For instance, a paste can be formed by combining baking soda and water, which can then be applied to the sheet. Gently rub the paste onto the surface using a soft cloth and rinse it off thoroughly. Furthermore, vinegar or lemon juice can be employed to eliminate stains or spots. Applying a small quantity of vinegar or lemon juice to a cloth and rubbing it onto the stainless steel sheet, followed by rinsing and thorough drying, can effectively remove such blemishes. It is imperative to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet before employing it on the entire surface. This will ensure that no damage or discoloration occurs.

- Q:Are stainless steel sheets suitable for railway station platforms?

- Yes, stainless steel sheets are suitable for railway station platforms. They are durable, resistant to corrosion, and can withstand heavy foot traffic, making them ideal for this application. Additionally, stainless steel sheets are easy to clean and maintain, ensuring a safe and aesthetically pleasing platform for passengers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Recycled Stainless Steel 316 Sheet and Plate for Exporting

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords