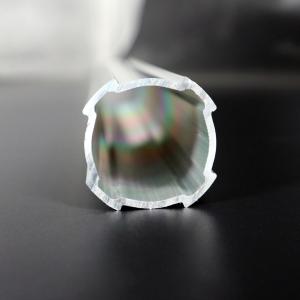

Rebar Price Per Foot Deformed Steel Bar HRB500 400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Usage and Applications of HRB500 Deformed Steel Bar:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

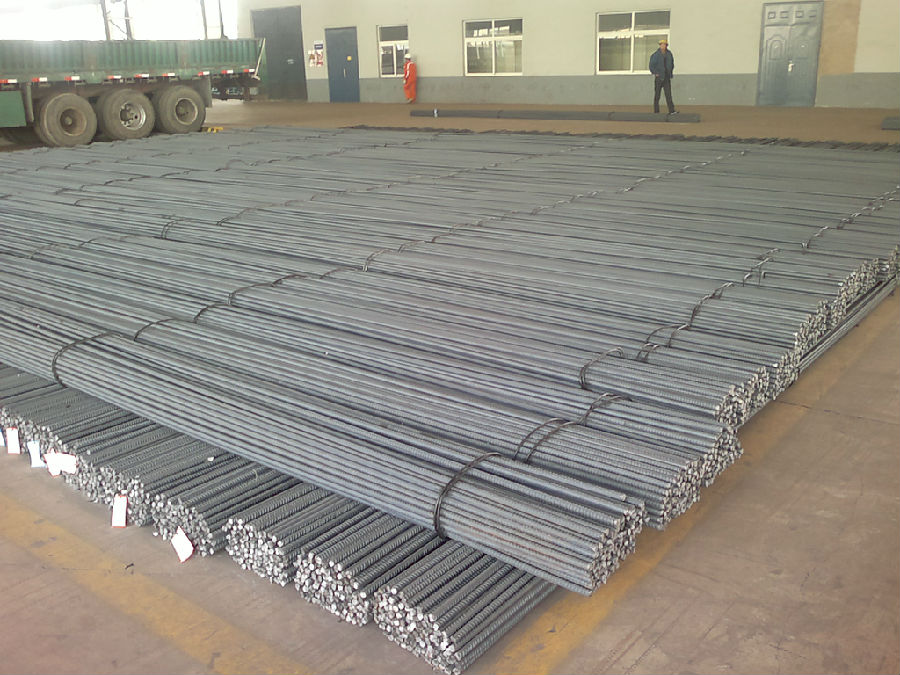

Packaging & Delivery of HRB500 Deformed Steel Bar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

Deformed Steel Bar in stock

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q:How can steel rebars be recycled after their service life?

- Steel rebars can be recycled after their service life through a process called steel scrap recycling. This involves collecting the used steel rebars, sorting them, and then melting them down in a furnace. The molten steel is then shaped into new rebars or other steel products. This recycling process not only helps reduce the demand for raw materials but also minimizes waste and environmental impact.

- Q:What is the role of steel rebars in bridge deck construction?

- Steel rebars play a crucial role in bridge deck construction as they provide reinforcement and strength to the structure. They are used to distribute and withstand the load and stresses that the bridge deck may experience, ensuring its stability and durability over time.

- Q:Can steel rebars be used in structures with high resistance to abrasion?

- Structures that require high resistance to abrasion can benefit from the use of steel rebars. Reinforced concrete structures often incorporate steel rebars to enhance their strength and durability. The specific steel chosen for rebars is known for its exceptional tensile strength and ability to withstand various environmental conditions. While the rebars themselves may not possess inherent resistance to abrasion, the concrete surrounding them offers protection against this. When properly designed and constructed, reinforced concrete structures with steel rebars can endure significant levels of abrasion without compromising their structural integrity. For areas with particularly harsh abrasion or corrosive environments, epoxy-coated rebars can be employed to provide an additional layer of protection against both abrasion and corrosion.

- Q:Can steel rebars be used in blast-resistant building construction?

- Yes, steel rebars can be used in blast-resistant building construction. Steel rebars provide strength and reinforcement to the concrete structure, making it more resilient against blast forces. Additionally, steel rebars can be designed and installed in a way that enhances the blast resistance of the building, helping to minimize damage and protect occupants in the event of an explosion.

- Q:How do steel rebars impact the overall construction cost estimation process?

- Steel rebars have a significant impact on the overall construction cost estimation process. These reinforcing bars are crucial components in reinforced concrete structures, providing strength and durability to the building. As such, their inclusion in cost estimation is essential for accurately assessing the total project cost. Firstly, steel rebars contribute to the material cost of the construction project. Since rebars are typically priced based on weight, the quantity and size of rebars required for the structure directly affect the material cost estimation. The accurate identification and quantification of rebars are necessary to ensure an appropriate budget allocation for the project. Moreover, steel rebars also influence the labor cost estimation. Installing rebars requires skilled labor, and the time and effort involved in cutting, bending, and placing the rebars must be considered. The complexity of the reinforcement design, such as intricate shapes or complex detailing, can increase labor costs. Therefore, accurate estimation of rebars allows for better planning of labor resources and cost allocation. In addition to material and labor costs, steel rebars impact other aspects of the construction cost estimation process. For instance, the weight and placement of rebars affect the structural design, which can influence the cost estimation of the concrete mix design and formwork requirements. The size and spacing of rebars may also impact the excavation and foundation costs, as well as the overall project timeline. Furthermore, steel rebars contribute to the long-term costs of the construction project. The quality and durability of rebars directly affect the lifespan and maintenance requirements of the structure. Investing in high-quality rebars can reduce future maintenance and repair costs, as well as enhance the overall life cycle cost analysis of the project. In conclusion, steel rebars have a significant impact on the overall construction cost estimation process. Accurate estimation of rebars is essential for determining the material and labor costs, as well as influencing other cost-related aspects of the project. It allows for precise budget allocation, resource planning, and consideration of long-term costs, ultimately leading to a more reliable and comprehensive construction cost estimation.

- Q:How do steel rebars bond with concrete?

- Steel rebars bond with concrete through a process called mechanical interlock, where the rough surface of the rebar provides better adhesion to the concrete. Additionally, the alkaline environment of the concrete forms a thin layer of iron oxide on the surface of the rebar, which further enhances the bond and prevents corrosion.

- Q:Are there any limitations on the length of steel rebars?

- There are limitations on the length of steel rebars, which are typically set by industry standards and guidelines. These limitations are mainly determined by practical and logistical factors. One limitation is related to transportation and handling of rebars. Steel rebars are typically manufactured in long lengths, often up to 60 feet (18 meters) or more. However, due to the weight and stiffness of steel rebars, it becomes challenging to transport and maneuver such long lengths. Therefore, rebars are often cut into shorter lengths for ease of transportation and handling on construction sites. Another limitation is related to the structural integrity of the rebars. Longer rebars may be more prone to bending, warping, or sagging, which can compromise their effectiveness in reinforcing concrete structures. To ensure structural integrity, rebars are often limited to specific lengths based on the specific application and design requirements. Additionally, there may be limitations imposed by local building codes and regulations. These codes and regulations aim to ensure the safety and durability of structures. They may specify the maximum length of steel rebars that can be used in different construction applications to meet the required standards and ensure the structural integrity of the building. In summary, while steel rebars can be manufactured in long lengths, practical considerations, structural integrity, and local regulations often impose limitations on their length. These limitations are in place to ensure the efficient handling and transportation of rebars, maintain their structural integrity, and comply with building codes and regulations.

- Q:Can steel rebars be used in pre-tensioned concrete structures?

- No, steel rebars cannot be used in pre-tensioned concrete structures. Pre-tensioned concrete structures require the use of high-strength, prestressed steel strands that are tensioned before the concrete is cast, providing the necessary strength and structural integrity.

- Q:What is the recommended method for tying steel rebars together?

- The recommended method for tying steel rebars together is typically using steel wire or rebar tying tools to secure the rebars in place. This ensures a strong and secure connection between the rebars, providing structural integrity to the reinforced concrete.

- Q:Can steel rebars be used in the construction of offshore oil and gas platforms?

- Yes, steel rebars can be used in the construction of offshore oil and gas platforms. Steel rebars are commonly used as reinforcement in concrete structures and can provide the necessary strength and durability required for offshore platforms.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rebar Price Per Foot Deformed Steel Bar HRB500 400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords