Rebar Menards Stainless HRB500 Deformed Steel Bar 6m, 9m, 12m or as Required

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications of Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required:

Standard | GB | HRB500 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Payment term | TT or L/C | ||

Application | mainly used in construction industry to reinforce concrete structures and so on | ||

Quality | First quality, the goods are from Chinese big manufacturers. | ||

Type | Hot rolled deformed steel bar | ||

Brand name | DRAGON | ||

Chemical Composition: (Please kindly find our chemistry of our material based on HRB500 as below for your information)

Grade | Technical data of the original chemical composition (%) | ||||||

C | Mn | Si | S | P | V | ||

HRB500 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.08-0.12 | |

Physical capability | |||||||

Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | |||||

≥500 | ≥630 | ≥12 | |||||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m bar(kg) |

6 | 28.27 | 0.222 | 2.664 |

8 | 50.27 | 0.395 | 4.74 |

10 | 78.54 | 0.617 | 7.404 |

12 | 113.1 | 0.888 | 10.656 |

14 | 153.9 | 1.21 | 14.52 |

16 | 201.1 | 1.58 | 18.96 |

18 | 254.5 | 2.00 | 24 |

20 | 314.2 | 2.47 | 29.64 |

22 | 380.1 | 2.98 | 35.76 |

25 | 490.9 | 3.85 | 46.2 |

28 | 615.8 | 4.83 | 57.96 |

32 | 804.2 | 6.31 | 75.72 |

36 | 1018 | 7.99 | 98.88 |

40 | 1257 | 9.87 | 118.44 |

50 | 1964 | 15.42 | 185.04 |

Usage and Applications of Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of HRB500 Deformed Steel Bar:

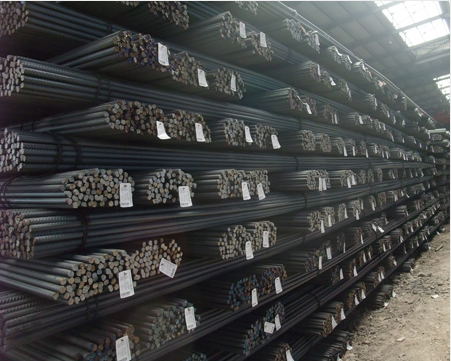

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

Deformed Steel Bar in stock

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:What are the different types of steel rebars used in bridge piers?

- The different types of steel rebars commonly used in bridge piers include epoxy-coated rebars, galvanized rebars, stainless steel rebars, and carbon steel rebars.

- Q:What are the different grades of steel rebars?

- The different grades of steel rebars include Grade 40, Grade 60, and Grade 75.

- Q:How are steel rebars tested for quality and compliance with standards?

- Steel rebars are tested for quality and compliance with standards through various methods. These include visual inspections, dimensional checks, and mechanical tests. Visual inspections involve examining the rebars for any surface defects, such as cracks or deformations. Dimensional checks ensure that the rebars meet the required size, length, and shape specifications. Mechanical tests are conducted to assess the rebars' tensile strength, yield strength, elongation, and other mechanical properties. These tests involve subjecting the rebars to tension or bending to determine their ability to withstand loads and deformations. Compliance with standards is ensured by conducting these tests in accordance with established protocols and guidelines set by relevant regulatory bodies or organizations.

- Q:Do steel rebars have any impact on the fire resistance of a structure?

- Yes, steel rebars can have an impact on the fire resistance of a structure. Steel is a good conductor of heat, and when exposed to high temperatures during a fire, it can transfer heat to the surrounding concrete. This can cause the concrete to crack or spall, reducing its fire resistance. However, properly designed and installed fire-resistant coatings or concrete coverings can provide additional protection to steel rebars and improve the fire resistance of the structure.

- Q:What is the weight of a typical steel rebar?

- The size and length of a steel rebar can cause its weight to fluctuate. Nevertheless, a frequently employed size is the #4 rebar, boasting a 1/2 inch diameter. A #4 rebar usually carries a weight of approximately 0.67 pounds per foot or 9.5 pounds per 14-foot span. It is crucial to keep in mind that weights will vary for distinct sizes of steel rebar, thus necessitating consideration of the precise size and length in weight determination.

- Q:What is the difference between plate and steel?

- Screwed steel is a kind of thread steel, refers to the steel surface spiral rib ribbed steel, steel wire like also refers to as disc together.

- Q:How do steel rebars affect the overall structural stability during construction?

- Steel rebars play a crucial role in enhancing the overall structural stability during construction. These reinforcement bars are typically embedded within concrete structures to provide additional strength and support. They help to distribute the load evenly across the entire structure, minimizing the risk of failure and increasing the overall stability. One of the main benefits of using steel rebars is their high tensile strength. Concrete is strong in compression but weak in tension, and steel rebars help to compensate for this weakness by resisting tensile forces. By reinforcing the concrete with steel rebars, the structure becomes more resistant to cracking and deformation, ensuring its durability and longevity. Moreover, steel rebars improve the ductility of the structure. Ductility refers to the ability of a material to undergo deformation without breaking or fracturing. During an earthquake or other external forces, the steel rebars allow the structure to flex and absorb energy, reducing the risk of catastrophic failure. This enhances the overall stability and safety of the construction. Additionally, steel rebars enhance the structural integrity of the construction by preventing the propagation of cracks. When cracks occur in the concrete, the steel rebars provide a pathway for stress transfer, preventing the cracks from spreading and compromising the overall stability of the structure. Furthermore, steel rebars contribute to the structural stability by reinforcing critical areas of the construction, such as columns, beams, and slabs. These elements are subjected to significant loads and stresses, and the presence of steel rebars ensures their ability to withstand these forces, preventing collapse or structural failure. In summary, steel rebars greatly affect the overall structural stability during construction. They enhance the tensile strength of concrete, improve ductility, prevent crack propagation, and reinforce critical areas of the structure. Their incorporation ensures that the construction can withstand various loads, external forces, and environmental conditions, providing a robust and stable building that meets safety standards and regulations.

- Q:How do steel rebars affect the overall sustainability of a structure?

- The overall sustainability of a structure is significantly influenced by steel rebars. To begin with, the utilization of steel rebars adds to the building's strength and durability, ensuring its longevity and decreasing the need for frequent repairs or replacements. As a result, the consumption of raw materials and energy required for construction is reduced, making the structure more sustainable. Moreover, steel rebars aid in improving the structural integrity of a building, rendering it more resilient to natural disasters like earthquakes and hurricanes. By enhancing the safety and resilience of the structure, steel rebars minimize the potential for damage and loss, thereby reducing the environmental impact associated with reconstruction and waste generation. Additionally, at the end of a building's life cycle, steel rebars can be recycled. Steel is highly recyclable, and the reuse of steel rebars significantly decreases the demand for virgin steel production and the related carbon emissions. Steel recycling also conserves natural resources and reduces landfill waste, making it a more sustainable alternative to using other materials. Furthermore, the incorporation of steel rebars in structures allows for greater design flexibility and adaptability. This implies that buildings can be easily modified or repurposed, reducing the necessity for demolition and reconstruction. The ability to repurpose existing structures reduces waste and energy consumption, contributing to the overall sustainability of the built environment. In conclusion, steel rebars have a positive impact on the overall sustainability of a structure through their durability, strength, and recyclability. By enhancing the longevity, safety, and adaptability of a building, steel rebars decrease the environmental impact associated with construction, maintenance, and demolition.

- Q:What are the different types of steel rebars used in building construction?

- Building construction utilizes various types of steel rebars, each possessing distinct characteristics and applications. Among the prevalent variants: 1. Mild Steel Rebars, also referred to as black bars, find extensive usage due to their lower carbon content, rendering them suitable for general construction purposes. 2. High Strength Deformed (HSD) Bars, heat-treated rebars exhibiting greater yield strength than mild steel rebars, feature a ribbed surface that enhances concrete adhesion. Consequently, they are ideal for load-bearing structures. 3. Epoxy-Coated Rebars employ an epoxy resin coating to shield against corrosion, preventing direct contact with moisture and chemicals, thereby prolonging the structure's lifespan. 4. Galvanized Rebars, coated with zinc, serve as a protective barrier against rust and corrosion. Even if the coating sustains damage, the zinc layer acts as a sacrificial layer, impeding steel corrosion. 5. Carbon Steel Rebars, crafted from carbon steel, boast superior tensile strength compared to mild steel rebars. They are commonly utilized in high-rise buildings and hefty construction projects. 6. Stainless Steel Rebars, known for their exceptional corrosion resistance, find application in structures enduring harsh environments or chemical exposure. Although pricier, they deliver unmatched durability. 7. European Rebars (Euro Rebars), adhering to European standards and featuring specific markings indicating their grade and properties, enjoy widespread employment in European construction ventures. The selection of rebar types hinges on factors such as the structure's intended purpose, environmental conditions, and desired strength. Opting for the appropriate rebar variety is crucial to ensure the building's stability and longevity.

- Q:Can steel rebars be used in tunnels or underground mines?

- Yes, steel rebars can be used in tunnels or underground mines. Steel rebars are commonly used in construction projects to reinforce concrete structures, and tunnels and underground mines are no exception. Reinforcing steel bars provide additional strength and stability to the concrete used in tunnel linings or mine shafts. They help resist the forces exerted by the surrounding soil or rock, prevent cracking or collapse, and increase the overall durability and longevity of the structure. Steel rebars are selected based on their specific characteristics, such as diameter, grade, and corrosion resistance, to ensure they meet the design requirements and are suitable for the specific underground conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rebar Menards Stainless HRB500 Deformed Steel Bar 6m, 9m, 12m or as Required

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords