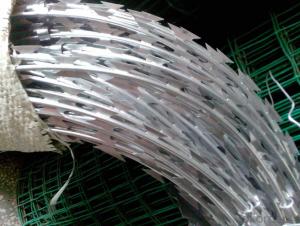

Razor Barbed Wire (Galvanized and SUS)Galvanized And PVC Coated Razor Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Material: High quality low carbon steel wire,Stainless steel wire,Medium carbon steel wire(Galvanized,Plastic coated,Plastic sprayed)

Style:BTO or CBT

Thickness: 0.5-0.6mm

Bar Length and width:12--67mm

Characteristics:

With beautiful and sharp blades and strong core wire,razor wire has the features of good deterrent effects,nice appearance,easy instrallation,economical and practical and other properties.

Application:

Razor barbed wire is widely used in apartment houses,organizations units,prison,frontier defense,military fields and other sites requiring severe fencing and security.

Outside Diameter | No. of Loops | Standard Length per Coil | Type | Notes |

450mm | 33 | 7-8M | CBT-60.65 | Single coil |

500mm | 56 | 12-13M | CBT-60.65 | Single coil |

700mm | 56 | 13-14M | CBT-60.65 | Single coil |

960mm | 56 | 14-15M | CBT-60.65 | Singlecoil |

450mm | 56 | 8-9M (3 CLIPS) | BTO-10.12.18.22.28.30 | Cross type |

500mm | 56 | 9-10M (3 CLIPS) | BTO-10.12.18.22.28.30 | Crosstype |

600mm | 56 | 10-11M (3 CLIPS) | BTO-10.12.18.22.28.30 | Cross type |

600mm | 56 | 8-10M (5 CLIPS) | BTO-10.12.18.22.28.30 | Cross type |

700mm | 56 | 10-12M (5 CLIPS) | BTO-10.12.18.22.28.30 | Cross type |

800mm | 56 | 11-13M (5 CLIPS) | BTO-10.12.18.22.28.30 | Cross type |

900mm | 56 | 12-14M (5 CLIPS) | BTO-10.12.18.22.28.30 | Cross type |

960mm | 56 | 13-15M (5 CLIPS) | BTO-10.12.18.22.28.30 | Cross type |

980mm | 56 | 14-16M (5 CLIPS) | BTO-10.12.18.22.28.30 | Cross type |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Hot Dipped Galvanzied Razor Wire Galvanized Iron Wire Black Wire?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②What is your Technical Information of Hot Dipped Galvanzied Razor Wire Galvanized Iron Wire Black Wire?

1).Material: super carbon steel

2).Processing by drawing, hot-dip zinc-plating

3).Standard wire gauge from 8# to 24#

4).Thick zinc-coating layer

5).Super in corrosion resistance

6).Firm coating layer

7).Custom size available

10 to 15g Zinc Coating and 35kg Tensile Strength Iron Wire Electro Galvanized Iron Wire

③How long can we receive the product after payment?

In the purchase of Galvanized Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served。

Hot Dipped Galvanzied Razor Wire Galvanized Iron Wire Black Wire

- Q: i need to know what color the wires are to hook up a stereo in my friends truck. her factory radio was stolen and they stole the factory plug

- This Site Might Help You. RE: 98 dodge dakota stereo wiring diagram, what are the speaker wire colors? i need to know what color the wires are to hook up a stereo in my friends truck. her factory radio was stolen and they stole the factory plug

- Q: ok so the passenger side back floorboard was getting wet and i believe the water to have corroded the wiring to my radio i've taken care of the water problem and know how to reconfigure the wiring but do i need to be worried about the security system while tinkering with the wiring see as how sensitive the security in these cars are i figured id check and see what you guys have to say about this pls also give resources as to how you know

- you can go to best buy and order a new wiring harness, for your car. all you do is plug it in, to your car and SOUND system and alarm

- Q: Would crepe paper stick on chicken wire?

- Crepe paper needs an adhesive to make it stick to a surface, such as white glue. However, it gets messy once dampened, as the colors may bleed. Instead, I would consider working with paper mache or plaster gauzing strips, which would provide a strong skin over the chicken wire. Both can be primed with gesso then decorated with acrylic paints. If this is a sculptural piece you want to keep, we would also suggest varnishing it for protection.

- Q: in hooking up a hot wire from the battery to a toggle switch inside a vehicle, i ran a seperate ground wire to the body, there are 2 wires coming from the unit i need to hook to the toggle switch.how do i test to see which one of those is a hot wire? i am not too smart at this. ty kindly

- Depends on what your hooking up? Look at the unit where the wires go in and there may be a +(hot) or -(ground) marking, and the ground wire is usually black and the hot is usually red,orange or yellow.

- Q: how do i wire a dual 2 ohm sub to an amp at 2 ohm

- You can't. Dual 2 ohm subs can only be wired at 1 ohm or 4 ohm. To run an amp at a 2 ohm load you need a dual 4 ohm sub. You can get a second dual 2 ohm sub to match and then they can be wired together at a 2 ohm load.

- Q: I know that there are wired routers, and wireless routers. Do wired routers do the same thing as wireless routers, without wireless capabilities?

- Most if not all wireless routers also work wired! Nearly all of them have at least four wired ports. The access point is the wireless connector, it just connects wireless capable machines to the exact same point within the router as the wired plugs do. A Wired router does not have the internal access point. With a wired router you can add wireless ability by simply adding an access point to them. The AP (access points) cost about as much as a full wireless router so you don't see them used very often but they are available. All the wireless does is eliminate the need for a local cable. Really that's all it does. Any computer connected to a router is connected to the router, wired or wireless makes no difference, although as a general statement the wired machines will be faster! So yes wired and wireless routers do exactly the same thing, they route local traffic for several machines to one broadband connection.

- Q: The t-stat comes with EIT module. that wires to the t-stat and the furnace. I'm having trouble with the module to furnace wiring.

- from the thermostat you match 1,2,3 wires to the module, from the module to the furnace. - R to R (this is your 24V hot) W to W (furnace 24V input G to G (fan for cooling 24V input) Y to Y (cooling 24V input), there should also be another wire that connects with this that goes to the condensing unit C to C ( Common - must have this connected for IAQ to work) as with the Y, there should be another wire to connect to this that goes to the condensing unit. - maybe W2 to W2 if you have a 2 stage furnace, you'll know if you have a 2 stage furnace because the W2 connection on the furnace will be present. - maybe Y2, if you have 2-stage cooling. if you have a humidifier connect both wires from the humidifier selinoid valve to each of the HUM terminals.

- Q: I bought a bathroom vent fan today, the one that was in there hasnt worked since we bought the house. Anyways, i have a black wire, and a white wire coming from the light switch on the wall ran up to the ceiling where the fan is, and a black, white, and GREEN comin off the new fan i bought. Do i need to get in the attic and run a ground wire from outlet to fan? Or are the black and white good enough? The old fan didnt have a ground wire, just the other 2. Any info is greatly appreciated. Thanks

- Green wire should be screwed into the inside of the receptacle box or pigtailed to the bare copper wire in the back of the box. If neither a bare wire or a green screw is present, call an electrician to run proper wiring to the box

- Q: so im doing a custom buggy and i need so different colored wire im looking for a place to get lots of different colored wire for cheap

- Quick wire / Saint wire cable company. painless wiring company There are other companies that sell universal harnesses that already have a fuse box with the basic circuits already done, and some blanks to run to whatever accessory you need. It's the easiest thing to do.

- Q: does copper, bell, or speaker wire carry energy faster

- If he is an Electrician than my guess is that the wire is solid copper (not stranded). While this will technically work, it is not very flexible and it would be single wire which could mean getting the polarity (+ and -) easily confused. Save yourself the headache and just buy some 12 gauge stranded speaker wire. (It's not that expensive).

Send your message to us

Razor Barbed Wire (Galvanized and SUS)Galvanized And PVC Coated Razor Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches