Carrier Air Conditioner Aluminum Coil - PVDF Painted Aluminium Coil with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of PVDF Painted Aluminium in Coil Form With Best Quality Description

PVDF Painted Aluminium in Coil Form With Best Quality is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of PVDF Painted Aluminium in Coil Form With Best Quality

PVDF Painted Aluminium in Coil Form With Best Quality | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

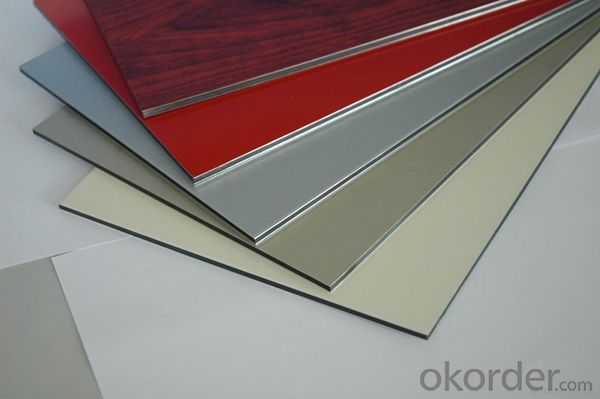

3. Application of PVDF Painted Aluminium in Coil Form With Best Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of PVDF Painted Aluminium in Coil Form With Best Quality

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of PVDF Painted Aluminium in Coil Form With Best Quality

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

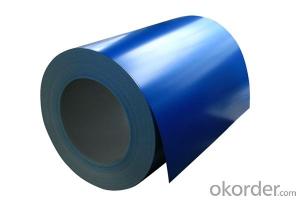

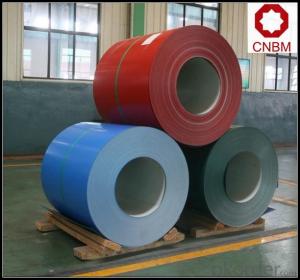

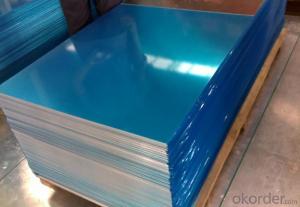

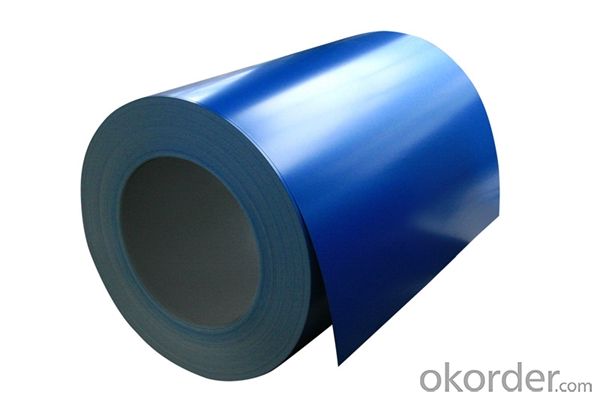

6. Image of PVDF Painted Aluminium in Coil Form With Best Quality

7. Package and shipping of PVDF Painted Aluminium in Coil Form With Best Quality

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in high-radiation environments?

- Aluminum coils can be used in high-radiation environments, but their performance and durability may be affected depending on the level of radiation exposure. Aluminum is a relatively good conductor of heat and electricity, making it a suitable material for many applications, including coil systems. However, when exposed to high levels of radiation, aluminum can become more susceptible to degradation and corrosion. In high-radiation environments, the primary concern is the potential for radiation-induced damage to the material. Aluminum is considered to have relatively low radiation resistance compared to other metals, such as stainless steel or titanium. As a result, prolonged exposure to high radiation levels can lead to structural changes, including embrittlement and loss of mechanical properties. To mitigate these risks, several factors need to be considered. The specific radiation level, duration of exposure, and the intended application of the aluminum coils are critical in determining their suitability for use in high-radiation environments. Additionally, protective coatings or treatments can be applied to enhance the radiation resistance of the aluminum coils, increasing their durability and longevity. Ultimately, the decision to use aluminum coils in high-radiation environments should be based on a thorough assessment of the radiation levels, the potential risks, and the specific requirements of the application. Consulting with radiation experts and considering alternative materials may be necessary to ensure the best performance and safety in such demanding conditions.

- Q: i need to know if Aluminum absorbs radio waves (just the type that control an RC jet)

- Aluminum is a good conductor of electricity. If an object is completely encased in a conductor (forming a Faraday cage), the object will be shielded from radio waves. If the aluminum (or another conductor) covers only part of the object, radio waves may still reach it.

- Q: which metal is very common today and which one will be most common in future. steel or aluminum

- I'd say it's about even now. Each metal has its advantages and disadvantages. Al is lighter than Fe so it's favored in transportation; even though Al is more expensive than Fe it pays in fuel savings. Al replaced Fe in cans because we can taste Fe more easily. In the future look for composites to obsolete both metals.

- Q: How are aluminum coils used in the production of electronic devices?

- Aluminum coils play a crucial role in the production of electronic devices. They are commonly used as the primary material for manufacturing the internal components of electronic devices such as transformers, inductors, and electromagnets. These coils are made by winding aluminum wire around a core, creating a compact and efficient conductor for electrical currents. In transformers, aluminum coils are utilized to transfer electrical energy between two or more circuits. These coils enable voltage transformation by utilizing electromagnetic induction, where a varying current in one coil induces a voltage in another coil. This process is vital in stepping up or stepping down voltage levels, allowing efficient power distribution in electronic devices and electrical systems. Inductors, another essential component in electronic devices, are made using aluminum coils. An inductor resists changes in electrical current and stores energy in its magnetic field. Aluminum coils provide low resistance, high conductivity, and can handle high-frequency currents, making them ideal for inductor applications. They are used in various electronic devices such as power supplies, speakers, and filters to control current flow and regulate voltage. Additionally, aluminum coils are employed in the production of electromagnets, which are widely used in electronic devices. Electromagnets are created by passing an electric current through a coil to generate a magnetic field. Aluminum coils are preferred due to their lightweight nature and good thermal conductivity, allowing efficient heat dissipation in high-power applications. Furthermore, the use of aluminum coils in electronic devices offers advantages such as cost-effectiveness, lightweight construction, and excellent electromagnetic properties. The lightweight nature of aluminum enables the production of compact and portable electronic devices, making them more convenient for users. Moreover, aluminum's high thermal conductivity ensures efficient heat dissipation, which is crucial for preventing overheating and maintaining the proper functioning of electronic devices. In conclusion, aluminum coils are extensively used in the production of electronic devices for various applications such as transformers, inductors, and electromagnets. Their excellent electrical conductivity, lightweight construction, and thermal conductivity make them an ideal choice for efficient and reliable performance in electronic devices.

- Q: Can aluminum coil 3003H24 replace 3A21H14?

- Yes.

- Q: How do aluminum coils contribute to fire safety?

- Aluminum coils contribute to fire safety in various ways. First and foremost, aluminum is a non-combustible material, meaning it does not burn or support combustion. This makes it an excellent choice for applications where fire safety is paramount, such as in the construction industry. Aluminum coils are commonly used in the manufacturing of fire-resistant barriers and protective claddings. These barriers act as a shield, preventing the spread of flames and heat between different areas of a building. By containing the fire to its origin and preventing it from spreading, aluminum coils play a crucial role in limiting the damage caused by fires and ensuring the safety of occupants. Furthermore, aluminum coils are often used in the production of fire-resistant doors, windows, and curtain walls. These components are designed to withstand high temperatures and provide an effective barrier against the spread of fire and smoke. By using aluminum coils as the base material for these products, they can offer enhanced fire protection and help to prevent the rapid spread of flames in the event of a fire. In addition to being non-combustible, aluminum is also a highly conductive material. This property allows it to quickly dissipate heat, reducing the risk of ignition and minimizing the potential for fire accidents. Aluminum coils are often incorporated into heat exchange systems, such as HVAC units and refrigeration systems, where their thermal conductivity helps to regulate temperature and prevent overheating, thus reducing the risk of fire. Overall, aluminum coils contribute to fire safety by being non-combustible, acting as fire-resistant barriers, and being used in the production of fire-resistant doors and windows. Their ability to dissipate heat quickly also helps to minimize the risk of fire accidents. By utilizing aluminum coils in various fire safety applications, we can enhance the protection of buildings and ensure the safety of occupants in the event of a fire.

- Q: Are aluminum coils applicable in the manufacturing process of automobiles?

- <p>Yes, aluminum coils are widely used in automobile manufacturing. They are utilized in various components such as engine parts, body panels, and wheels due to their lightweight, corrosion resistance, and strength. Aluminum's recyclability and energy efficiency also make it an environmentally friendly choice for the automotive industry.</p>

- Q: Can aluminum coils be used for industrial piping?

- Industrial piping can indeed utilize aluminum coils. Aluminum, being a versatile and lightweight material, presents numerous advantages for industrial piping purposes. Its exceptional resistance to corrosion makes it a suitable choice across various industries such as chemical, petrochemical, and food processing. Moreover, aluminum coils are effortlessly manageable and can be molded into diverse configurations and dimensions, providing flexibility when designing and installing piping systems. Furthermore, aluminum's commendable thermal conductivity proves advantageous for applications that necessitate heat transfer. Nevertheless, it is crucial to carefully contemplate the specific requirements of the industrial process and seek advice from professionals to guarantee that aluminum coils are appropriate for the intended application.

- Q: I was going to buy a turkey roaster pan today and an elderly couple stopped me and told me to buy another one that was made of stainless steel instead of aluminum because aluminum does something to your brain. What is the story?Just curious. Does this also ring true for using a sheet of aluminum foil over baking sheets while cooking cookies or fries or something? I always coat my cookie sheets with foil. Just curious...

- For okorder /19

- Q: Calculate the specific heat of aluminum (in calories).mass of aluminum25.0 gmass of water23.2ginitial temperature of aluminum98.0Cinitial temperature of water20.0Cfinal temperature of water33.0Cround to three decimal places, do not include units.

- Heat gained by water = heat lost by aluminum Heat = H mass = m specific heat =c change in temperature = dT H = mcdT mcdT for water = mcdT for Al (23.2)(1.00)(13) = (25.0)(c(Al))(33-98) c(Al) = (23.2)(1.00)(13)/(25.0)(65) = 0.186 This value is just a bit below the known value of specific heat for aluminum, where c = 0.217 cal/g.C

Send your message to us

Carrier Air Conditioner Aluminum Coil - PVDF Painted Aluminium Coil with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords