Wholesale Roofing Aluminum Coil - Aluminium Coil with PVDF Coating Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coil with PVDF Coating Good Quality:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Coil with PVDF Coating Good Quality:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

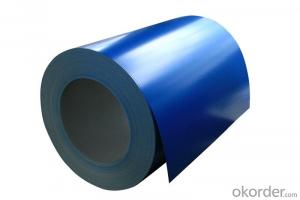

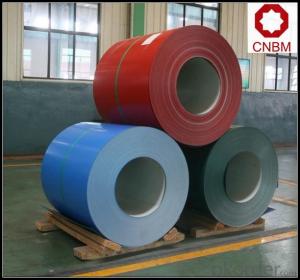

Images of the Aluminium Coil with PVDF Coating Good Quality:

Aluminium Coil with PVDF Coating Good Quality Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Coil with PVDF Coating Good Quality:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the potential applications of coil-brushed aluminum coils?

- Coil-brushed aluminum coils have a range of potential applications due to their unique properties. They can be used in interior design, architecture, automotive industry, appliances, electronics, and even in the manufacturing of furniture and decorative items. The brushed texture on the surface of the aluminum adds an aesthetic appeal and can be employed for creating modern, sleek, and sophisticated designs. Additionally, the durability and corrosion resistance of aluminum make it suitable for outdoor applications such as signage and cladding.

- Q: What are the common installation methods for aluminum coils?

- The common installation methods for aluminum coils include direct attachment, concealed fastening, and interlocking panel systems.

- Q: Can aluminum coils be used in marine or saltwater environments?

- Yes, aluminum coils can be used in marine or saltwater environments. Aluminum is highly resistant to corrosion, making it a suitable choice for applications in saltwater environments.

- Q: Can aluminum coils be used in food storage facilities?

- Yes, aluminum coils can be used in food storage facilities. Aluminum is a widely used material in the food industry due to its excellent properties such as its lightweight, durability, corrosion resistance, and heat conductivity. These qualities make aluminum coils suitable for various applications in food storage facilities. Aluminum coils can be utilized in refrigeration systems, air conditioning units, and food storage cabinets, among others. Additionally, aluminum is non-toxic and does not react with food or alter its taste, making it a safe option for food storage. However, it is important to ensure that the aluminum coils used in food storage facilities are properly cleaned and maintained to prevent any potential contamination.

- Q: What is the average lifespan of an aluminum coil?

- The average lifespan of an aluminum coil can vary depending on various factors such as the quality of the aluminum, external factors like exposure to weather conditions or chemicals, and how well it is maintained. However, on average, an aluminum coil can last anywhere from 20 to 30 years.

- Q: Can aluminum coils be used in high-pressure or high-temperature environments?

- Aluminum coils are not typically recommended for use in high-pressure or high-temperature environments. While aluminum is known for its high thermal conductivity and corrosion resistance, it has certain limitations when exposed to extreme conditions. In terms of high-pressure environments, aluminum coils may not possess the necessary strength and durability required to withstand the forces exerted by the pressurized system. Aluminum has a lower tensile strength compared to other metals like steel or titanium, which makes it more prone to deformation or failure under high pressure. Therefore, it is generally advised to use materials with higher strength and pressure ratings in such scenarios. Similarly, aluminum coils have a relatively low melting point compared to metals like steel or copper. The melting point of aluminum is around 660 degrees Celsius (1220 degrees Fahrenheit), which makes it susceptible to damage or failure in high-temperature environments. In applications where the temperature exceeds the melting point of aluminum, it is recommended to use materials with higher temperature resistance. However, it is worth mentioning that there are specialized alloys and coatings available that can enhance the high-temperature and high-pressure capabilities of aluminum. These modifications can improve its strength, heat resistance, and corrosion resistance, making it suitable for certain applications in extreme conditions. Nonetheless, the specific requirements and limitations of the intended environment should be carefully considered before deciding to use aluminum coils. Consulting with experts and considering alternative materials may be necessary to ensure the safety and efficiency of the system.

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Yes, aluminum coils can be used in the production of aircraft fuel tanks. Aluminum is a commonly used material in the aerospace industry due to its lightweight, strong, and corrosion-resistant properties. It is an ideal choice for fuel tanks as it can effectively withstand the harsh conditions and requirements of aircraft operations.

- Q: How do aluminum coils compare to other materials in terms of strength?

- Aluminum coils are known for their remarkable strength-to-weight ratio, making them highly competitive compared to other materials. While aluminum may not be as strong as certain metals like steel or titanium, it still possesses sufficient strength to meet the demands of various applications. The specific strength of aluminum coils refers to their strength relative to their weight, which is often superior to other materials. Additionally, aluminum coils offer exceptional corrosion resistance, which further enhances their durability and longevity. Although there may be stronger materials available, aluminum coils remain an excellent choice for many industries due to their favorable strength characteristics and numerous other benefits.

- Q: How are aluminum coils typically stored and transported?

- Aluminum coils, in order to safeguard them and avoid any harm, are typically stored and transported in a manner that guarantees their protection. They are commonly stored in a warehouse or storage facility, maintaining a vertical position to prevent any bending or warping. Regarding transportation, specialized coil trailers or flatbed trucks are often utilized to transport aluminum coils. These trailers are designed specifically to securely hold the coils in place during transit. Straps or bands are typically employed to fasten the coils tightly, preventing any movement or shifting while on the road. Furthermore, it is customary for aluminum coils to be enveloped in protective materials such as plastic or cardboard during transportation. This extra layer of protection serves to shield the coils from moisture, dirt, and other potential hazards. It is of utmost importance to handle aluminum coils with caution to avoid any damage, as even minor dents or scratches can impact their performance. Hence, employing appropriate storage and transportation methods is vital to ensure that the coils reach their destination in optimal condition.

- Q: How do aluminum coils contribute to noise reduction?

- There are multiple ways in which aluminum coils contribute to reducing noise. Firstly, aluminum, being a lightweight material, can effectively absorb and dampen sound waves. When utilized in coils, it aids in decreasing vibrations and minimizing the transmission of noise. Furthermore, aluminum possesses excellent thermal conductivity properties, which aid in dissipating heat and preventing temperature-related noises. This is particularly crucial in HVAC systems, where the noise generated by the equipment can be substantial. Moreover, aluminum coils can be designed with special features like grooves or fins that enhance their noise reduction capabilities. These features serve to increase the coil's surface area, facilitating better heat transfer and reducing noise levels. In general, aluminum coils offer an efficient and effective solution for noise reduction in a wide range of applications, making them a favored choice in industries where noise control is of utmost importance.

Send your message to us

Wholesale Roofing Aluminum Coil - Aluminium Coil with PVDF Coating Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords