PVD coated colored stainless steel/ Home Decoration Decorative Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications

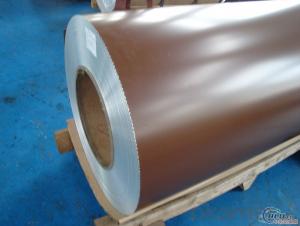

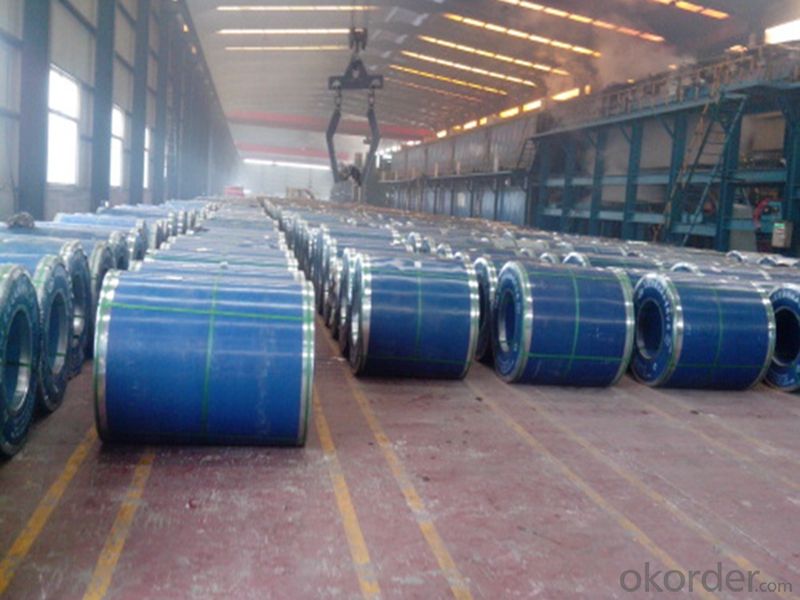

Prepaint Aluzinc Steel Coil

.Thicknee:0.10-1.20mm

.Width:600-1250mm

.Good quality and service

.Standard Export seaworthy

PVD coated colored stainless steel/ Home Decoration Decorative Sheets

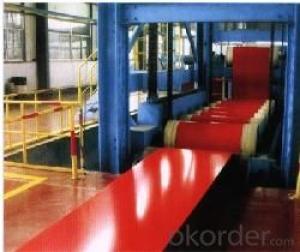

. coated colored stainless steel is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

. The base metals for Prepainted Steel Coil consist of cold rolled, galvanized The finish coats of Prepainted Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

2. PVD coated colored stainless steel/ Home Decoration Decorative Sheets

Product Description

| Commodity | PVD coated colored stainless steel/ Home Decoration Decorative Sheets | ||||||||

| Standard | Q/BQB445 JISG3322 EN10327 | ||||||||

| Grade | TDC51D+AZ/TDC52D+AZ/TS250GD+AZ/TS300GS+AZ/TS350+AZ/TS350GD+AZ/TS550GD+AZ/CGLCC/ | ||||||||

| CGLCD/CGLC490/CGLC570/DX51D+AZ/DX52D+AZ/S250GB+AZ/S300GD+AZ/S350GD+AZ/S550+AZ | |||||||||

| Thicknees | 0.16-1.2 mm | Width | 600-1250mm | ||||||

| Zinc Coating | AZ30-AZ150g/m2 | Coil Weight(Min or Max) | 3-8 tons | ||||||

| Coil Inner Diameter | 508mm | 610mm | Coil Outer Diameter(Max) | ||||||

| Color | Ral Color | As Customers' requirement | |||||||

| Surface Finish | Normal Coated | Embossed | Printed | ||||||

| Category Of Finish Coating | High-durability Polyester | Silicon Modified Polyesters | |||||||

| Polyvinylidene Fluoride | Polyester | ||||||||

| Anti-static | Easy-Cleaning | ||||||||

| Coating Type | Top Surface | Bottom Surface | |||||||

| Double Coated | Double Coated | ||||||||

| Double Coated | Single Coated | ||||||||

| Coating Thickness | Top Surface: | Back Surface: | |||||||

| Coating Structure | Primer | Finish Coating | |||||||

| Epoxy Primer | Polyester | ||||||||

| Polyester Primer | Silicon Modified Polyesters | ||||||||

| Water-soluble Acrylic Acid Primer | High-durability Polyester | ||||||||

| Polyurethane Primer | Polyvinylidene Fluoride | ||||||||

| Method of Test | <1>Acid/Alkaline-Resistance Test | <2>Test of Resistance to Neutral Mist | |||||||

| <3>Air Exposure Test | |||||||||

| Futher Process | Cut coil into Sheet | Corrugated Roofing Sheet | |||||||

Application | Construction | Outside | workshop,agricultural,warehouse,corrugated roof,wall,etc | ||||||

| Inside | doo,doorcase,light steel roof structure,vent gutter,etc | ||||||||

| Electial Appliance | refrigetator.washer,switch cabinet,etc | ||||||||

| Furniture | central heating slice,lampshade,etc | ||||||||

| Carrying Trade | clapboard,container,etc | ||||||||

| Others | writing panel,garbage can,timekeeper,etc | ||||||||

3. Applications

construction | workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door |

door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter | |

Electrical appliance | refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker |

Furniture | central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf |

Carrying trade | exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of color steel coils,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: I am a beginner (never played before!) and I am going to try to teach myself since I think it is a lovely instrument. I am fourteen-years-old so I am not 'adult-size', haha. Anyway, what is difference between nylon strings and steel strings?Thanks :)

- Make your choice based on the type of music you intend to play. Nylon strings are used primarily for classical, flamenco and folk music. Steel strings are used for pop, rock, blues, country, folk, bluegrass.... Both types of guitar are tuned the same, so you *can* play any style of music on either guitar. The big difference is in the tone. Nylon strings are rich and full...if perhaps a little mellow. Steel strings are twangy and have a bite to the sound. There are differences in the construction and feel of the guitars, but that's not critical to your decision. Match the guitar to the music you intend to play. At 14 yrs old, you are certainly big enough for a full sized guitar....and I'll bet you're still growing, right? Even full sized guitars still vary in the size of the body. Try a few out to see how well they fit your reach.

- Q: I'm planning to buy a pair of Doc Marten boots but I want some steel toed ones. I don't know if all of them are steel toed, or only some of them, or what?

- No, okorder /! Ps: if you don't want to buy them new, search off Ebay: there are tons of Dr Martens!!

- Q: How are steel coils inspected for dimensional accuracy after processing?

- Steel coils are inspected for dimensional accuracy after processing using various methods, such as manual measurement with precision tools, laser scanning technology, or automated vision systems. These inspection methods ensure that the dimensions of the steel coils meet the required specifications and tolerances, ensuring their quality and suitability for the intended applications.

- Q: How are steel coils used in the manufacturing of household appliances?

- Steel coils are used in the manufacturing of household appliances as they are shaped, cut, and formed into various parts such as panels, frames, and components. These coils provide strength, durability, and structural integrity to appliances like refrigerators, ovens, and washing machines, ensuring their stability and longevity.

- Q: What's the best material for color coated steel coil?

- Color steel roll is a kind of composite material, also called color coating steel plate. It is produced by continuous coating on the production line by surface degreasing and phosphating etc. after being coated with organic coating, the product is made by baking. Color steel roll is a composite material, both steel and organic materials, both of them a little. Both the mechanical strength of steel plate and easy molding performance, but also organic materials, good decoration, corrosion resistance.

- Q: Can steel coils be coated with color-changing materials?

- Yes, steel coils can be coated with color-changing materials. These materials are typically applied as a topcoat or overcoat on the steel surface, allowing the coils to exhibit different colors or hues based on external factors such as temperature, light, or chemical reactions. This coating technology can provide visual appeal, aesthetic versatility, and even functional benefits to steel coils in various applications.

- Q: What are the main steel coil producing countries?

- The main steel coil producing countries are China, Japan, India, the United States, and Russia.

- Q: How are steel coils used in the manufacturing of garage doors?

- Steel coils are used in the manufacturing of garage doors as they are the primary material for constructing the door panels. These coils are first formed into thin, flat sheets and then cut to the desired size. The sheets are then shaped and reinforced to create the panels that make up the structure of the garage door. The strength and durability of steel make it an ideal material for garage doors, providing security, insulation, and longevity.

- Q: And by how much? I'm pretty sure that sterling silver is stronger, but I'm wondering if I could still use a metal stamp to stamp into something that's stainless steel - if it would be soft enough?

- Sterling is always best, but, in the 30's and 40's India also plated silver with brass overlay, believe it or not. They thought the look would be more attractive to tourist and more Indian traditional. Pieces marked India have been found to be 80% silver with brass overlay. Several times I have taken India marked pieces that looked brass to a metallurgist and found they are actually 80% silver with brass coatings. Like anything else, this is not always the case, either way, pieces marked and numbered will draw attention.

- Q: How are steel coils used in the production of steel plates?

- Steel coils are used in the production of steel plates by being fed into a rolling mill where they are gradually flattened and shaped under high pressure. This process, known as hot rolling, transforms the steel coils into thin and flat plates that can be further processed and used in various industries such as construction, automotive, and manufacturing.

Send your message to us

PVD coated colored stainless steel/ Home Decoration Decorative Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords