Colored Aluminum Coil - PVC Coated Aluminium Coil Alloy 1100, 3003, 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of PVC Coated Aluminium Coil Alloy 1100 3003 5052

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

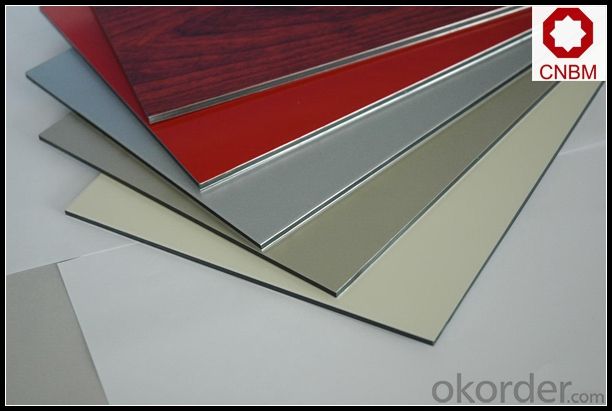

2. Application of PVC Coated Aluminium Coil Alloy 1100 3003 5052

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PVC Coated Aluminium Coil Alloy 1100 3003 5052

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

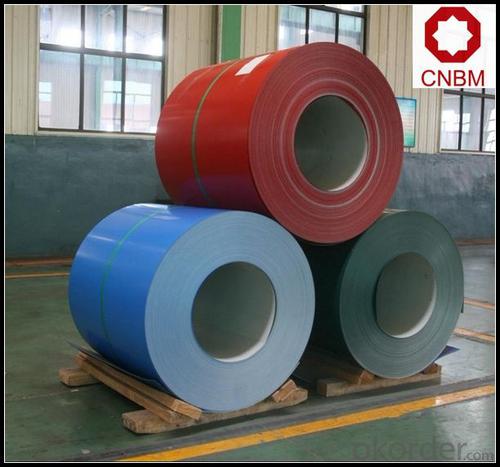

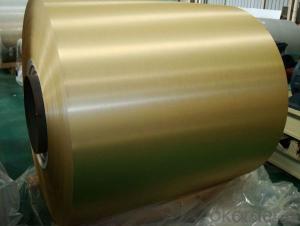

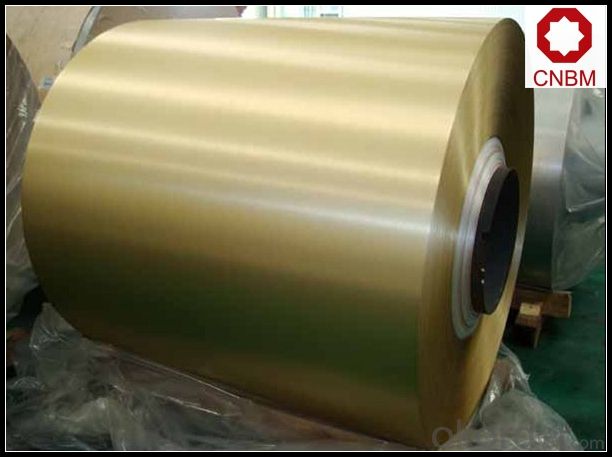

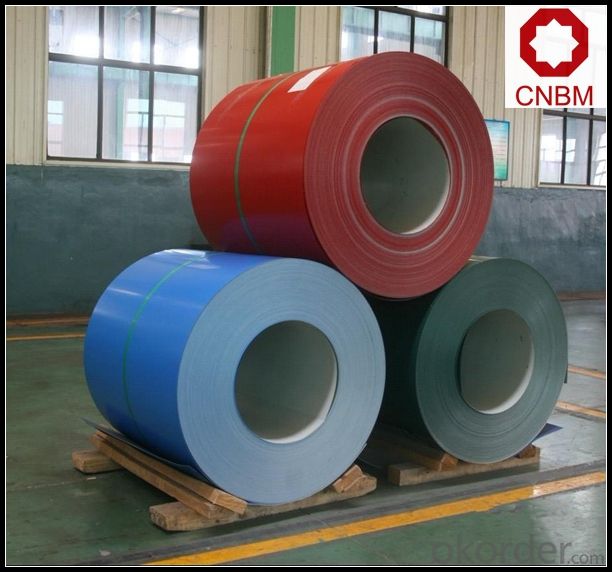

5. Image of PVC Coated Aluminium Coil Alloy 1100 3003 5052

6. Package and shipping of PVC Coated Aluminium Coil Alloy 1100 3003 5052

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in the production of heat shields?

- Yes, aluminum coils can be used in the production of heat shields. Aluminum is a popular choice for heat shields due to its excellent thermal conductivity, lightweight nature, and high reflectivity of radiant heat. Heat shields are typically designed to protect sensitive components or structures from excessive heat generated by engines, exhaust systems, or other sources. Aluminum coils can be formed into various shapes and sizes to create effective heat shields that can dissipate heat and prevent its transfer to the surrounding areas. Additionally, aluminum is corrosion-resistant, making it suitable for applications where heat shields may be exposed to harsh environments or chemicals. Overall, aluminum coils are a suitable material for the production of heat shields due to their thermal properties, versatility, and durability.

- Q: What are the potential applications of painted aluminum coils?

- The potential applications of painted aluminum coils are vast and diverse. They are commonly used in the construction industry for roofing, siding, and cladding applications due to their durability, weather resistance, and aesthetic appeal. Additionally, painted aluminum coils find applications in the manufacturing of transportation vehicles, such as trailers, buses, and railway cars, as they offer lightweight properties and corrosion resistance. Other potential uses include signage, electronics, household appliances, and various industrial applications where a combination of strength, versatility, and attractive appearance is required.

- Q: Can aluminum coils be utilized to create jewelry boxes and other decorative objects?

- <p>Yes, aluminum coils can be used to make jewelry boxes and other decorative items. Aluminum is lightweight, durable, and has a shiny finish that can add a touch of elegance to decorative pieces. It can be easily shaped and manipulated using various tools and techniques, such as bending, cutting, and engraving. Additionally, aluminum's resistance to corrosion makes it a practical choice for long-lasting decorative items. However, it's important to consider that working with aluminum may require specific skills and tools, and the final appearance can be influenced by the quality of the aluminum and the craftsmanship involved.</p>

- Q: How are aluminum coils processed for specific thicknesses?

- Aluminum coils are processed for specific thicknesses through a series of manufacturing steps. The process begins with the casting of molten aluminum into large ingots. These ingots are then rolled out into thin sheets using a hot rolling mill. The first step in achieving the desired thickness is hot rolling. The aluminum sheet is passed through a series of heated rollers that gradually reduce its thickness. This process is repeated multiple times, with the sheet being reheated between each pass. Hot rolling allows for the sheet to be elongated and thinned out. After hot rolling, the sheet may undergo a process called cold rolling. Cold rolling involves passing the hot rolled sheet through a set of cold rollers. This process further reduces the thickness and improves the surface finish of the aluminum. Cold rolling also increases the strength and hardness of the material. Next, the sheet is annealed, which involves heating it to a specific temperature and then allowing it to cool slowly. Annealing helps to relieve any internal stresses and improve the overall ductility of the aluminum. Once the desired thickness is achieved, the aluminum sheet is typically cut into coils using a slitting machine. The coils can then be further processed or used in various applications, such as in the manufacturing of automotive parts, packaging materials, or building construction. Overall, the process of processing aluminum coils for specific thicknesses involves hot rolling, cold rolling, annealing, and slitting. These steps ensure that the aluminum sheet meets the required thickness specifications and is ready for further use in various industries.

- Q: Can aluminum coils be used in architectural applications?

- Yes, aluminum coils can be used in architectural applications. Aluminum is a versatile and durable material that is commonly used in the construction industry for its lightweight nature, corrosion resistance, and ease of fabrication. Aluminum coils are often utilized in architectural applications such as roofing, cladding, and facades due to their ability to be easily formed into various shapes and sizes. Additionally, aluminum coils can be coated with different finishes to enhance their aesthetics and provide additional protection against weathering and fading. Overall, aluminum coils are a popular choice for architectural applications as they offer a combination of functionality, aesthetics, and longevity.

- Q: How are aluminum coils used in solar panels?

- Aluminum coils are used in solar panels as part of the construction and structure of the panel. They are used to hold the solar cells in place and provide a sturdy framework for the overall structure. Additionally, aluminum coils help with heat dissipation and ensure efficient functioning of the solar panel by preventing warping or damage caused by temperature fluctuations.

- Q: Is it possible to utilize aluminum coils in creating art pieces or decorative items?

- <p>Yes, aluminum coils can be used to make artworks or decorations. Aluminum's malleability and durability make it an excellent material for crafting. It can be bent, twisted, and shaped into various forms, allowing for creative expression in art and design. Additionally, aluminum's resistance to corrosion and weathering makes it suitable for both indoor and outdoor decorative pieces. Artists often appreciate its lightweight nature and the metallic finish that can be polished or painted, offering versatility in artistic applications.</p>

- Q: A piece of aluminum foil 0.550 mm thick and 1.00 cm square is allowed to react with bromine to form aluminum bromide?a) How many mole of aluminum were used? ( The density of aluminum is 2.699 g/cm3.)I keep getting the same answer which I know is wrong. I used a formula to get the volume and then the mass to get the moles, but maybe this is wrong. Could someone explain the process. I got 4.32 x 10-1 mol Al, but the answer is 5.50 x 10-3 mol Al.

- Okay. If you have .55mm thick, 1cm square of Al, you you have 55 cubic mm of Al. 55 cubic mm is .055 cubic centimeters of Al. .055 * denisty of Al (2.699 g/cm3) gives you .148 grams of Al. Al molecule weight is 27g/mole. So .148 g * (1 mole / 27 grams) = .00548 moles of Aluminum. That rounds to about 5.50 x 10-3 moles. I should also add that A) Remember when you are converting cubic units (such as mm3 into cm3), the conversion factor should also be cubed (so 1 cubic mm = 10^3 cubic cm). Also, not to be nit picky, but this question is dumb because aluminum foil would also have a good portion of aluminum oxide coating it...but I wouldn't bring that up to the teacher if I were you. :-)

- Q: Can a spring balance be used to accurately determine the weight of an aluminum coil?

- <p>Yes, you can use a spring balance to measure the weight of an aluminum coil, but the accuracy depends on the balance's specifications. Ensure the balance has a sufficient capacity to measure the coil's weight and is calibrated correctly. Keep in mind that spring balances are less precise than electronic scales, especially for heavy or sensitive measurements. For high accuracy, consider using an electronic scale designed for industrial use.</p>

- Q: This question asks for the method to measure the dimensions of an aluminum coil.

- <p>To measure the size of an aluminum coil, you'll need to measure its diameter, width, and thickness. Use a tape measure or a caliper to measure the coil's diameter and width. For the thickness, a micrometer or a coil thickness gauge can be used. Ensure the coil is laid flat and measure at several points to get an average thickness. If the coil is wound, you may need to unroll it partially to take accurate measurements. Always follow the manufacturer's guidelines for your specific measuring tools to ensure accuracy.</p>

Send your message to us

Colored Aluminum Coil - PVC Coated Aluminium Coil Alloy 1100, 3003, 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords