Aca Aluminum Coil Anodizing Corp Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

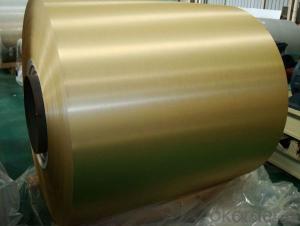

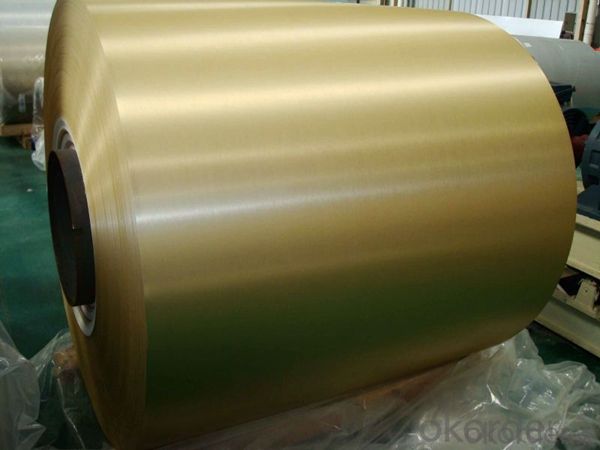

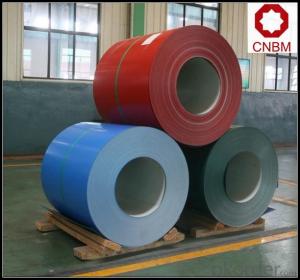

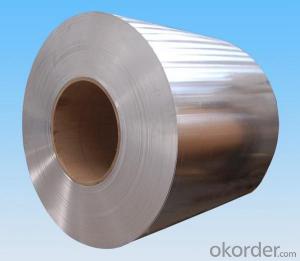

5. Image of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

6. Package and shipping of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the difference between hot-rolled and cold-rolled aluminum coils?

- The main difference between hot-rolled and cold-rolled aluminum coils lies in the manufacturing process and the resulting properties of the finished product. Hot-rolled aluminum coils are produced by heating aluminum ingots at high temperatures and then passing them through rollers to achieve the desired thickness and shape. This process makes the aluminum more malleable and allows for greater flexibility in terms of shape and size. Hot-rolled coils are typically larger in size and have a rougher surface finish compared to cold-rolled coils. On the other hand, cold-rolled aluminum coils are manufactured by cooling down the hot-rolled coils and then passing them through rollers at room temperature. This process not only reduces the thickness of the aluminum but also improves its surface finish, making it smoother and more aesthetically pleasing. Cold-rolled coils are typically thinner and have a more consistent thickness compared to hot-rolled coils. The differences in the manufacturing process and surface finish of these two types of coils result in different mechanical properties. Hot-rolled aluminum coils are generally less strong and have lower tensile strength compared to cold-rolled coils. However, hot-rolled coils are more ductile and can be easily formed and shaped without cracking. On the other hand, cold-rolled coils have higher tensile strength and are more suitable for applications requiring greater strength and durability. In summary, hot-rolled aluminum coils are larger, have a rougher surface finish, and are more malleable, while cold-rolled aluminum coils are thinner, have a smoother surface finish, and are stronger. The choice between hot-rolled and cold-rolled coils depends on the specific requirements of the application, such as strength, surface finish, and formability.

- Q: Can aluminum coils be used in chemical processing plants?

- Yes, aluminum coils can be used in chemical processing plants. Aluminum is resistant to many chemicals, especially in non-acidic environments. It is lightweight, has good thermal conductivity, and can withstand high temperatures, making it suitable for various applications in chemical processing plants.

- Q: What are the different coil slitting methods used for aluminum coils?

- Aluminum coils can be slit using various methods, each offering distinct advantages and applications. Here are a few commonly used techniques: 1. Rotary Shear Slitting: Employing rotating circular knives, this method achieves precise and speedy cutting of aluminum coils into narrower strips. It is ideal for high-volume production of consistently sized narrow strips. 2. Loop Slitting: This method involves passing the aluminum coil through a loop, where rotating knives make the cuts. Loop slitting enables fast processing while minimizing the risk of surface damage, making it suitable for thinner gauge coils. 3. Double Knife Slitting: Using two blades, this technique makes parallel cuts along the length of the aluminum coil. It is best suited for thicker gauge coils and can produce wider strips compared to other methods. 4. Scissors Slitting: This versatile method deploys a pair of scissors-like blades to cut the aluminum coil into strips. It can handle a wide range of coil thicknesses and is commonly used in smaller scale operations or when precise width tolerances are not critical. 5. Crush Slitting: Here, the aluminum coil is pressed against a hardened roller or blade, causing it to deform and rupture along the desired cutting line. Crush slitting is ideal for delicate materials or when minimal burr formation is desired. Each slitting method has its own advantages and limitations, and the choice depends on factors such as coil thickness, desired strip width, production volume, and surface quality requirements. Selecting the appropriate method is crucial for efficient and accurate slitting of aluminum coils.

- Q: What are the different ACP (Aluminum Composite Panel) applications for aluminum coils?

- Some of the different applications for aluminum coils in Aluminum Composite Panels (ACP) include building facades, signage, interior decoration, cladding, and insulation. The versatility and durability of ACP make it suitable for a wide range of architectural and construction projects.

- Q: I'm having trouble with another chem problemAluminum sulfide reacts w/water to form aluminum hydroxide and hydrogen sulfide. Write the balanced chemical equation for this reaction and find how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide.I already found the balanced equation but I need help on finding how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide. Can someone please explain how it's done?

- You use the given grams of Aluminum Sulfide, and use stoichiometry. First convert the Aluminum Sulfide from grams to moles [14.2g (1 mole of Aluminum Sulfide/total mass of Aluminum sulfide)]. Then, set up a mole ratio of Aluminum Sulfide to Aluminum Hydroxide (you do this by creating a ratio of the coefficients of both Aluminum Sulfide and Aluminum Hydroxide from your balanced equation; moles of Aluminum Hydroxide/miles of Aluminum Sulfide). And then finally convert back to grams (total mass of Aluminum Hydroxide/ 1 mole of Aluminum Hydroxide). In total, it should look like this: [14.2(1 mol Al Sulfide/mass of Al Sulfide)(mols of Al Hydroxide/mols of Al Sulfide)(mass of Al Hydroxide/1 mol of Al Hydroxide)]

- Q: Can aluminum coils withstand high temperatures?

- Yes, aluminum coils can withstand high temperatures. Aluminum has a relatively high melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit). This makes it suitable for applications that involve high-temperature environments. Additionally, aluminum has excellent thermal conductivity, which allows it to dissipate heat efficiently. This property makes aluminum coils commonly used in heat exchangers and various heating applications. However, it is important to note that the specific temperature limit for aluminum coils may vary depending on the specific alloy and application.

- Q: What are the different coil embossing options available for aluminum coils?

- There are several coil embossing options available for aluminum coils, each offering unique textures and patterns. Some of the common coil embossing options for aluminum coils include stucco embossing, diamond embossing, and 3-bar embossing. Stucco embossing creates a textured pattern that resembles the appearance of a stucco wall. This embossing option is popular for its ability to hide surface imperfections and provide a visually appealing finish. Stucco embossed aluminum coils find applications in various industries such as construction and automotive. Diamond embossing creates a diamond-shaped pattern on the aluminum coil's surface. This embossing option is known for its durability and ability to enhance the coil's strength. Diamond embossed aluminum coils are commonly used in flooring, roofing, and decorative applications. 3-bar embossing creates three parallel lines on the aluminum coil's surface. This embossing option adds a unique visual appeal and provides enhanced traction, making it ideal for applications that require slip resistance, such as ramps and walkways. Apart from these options, there are several other embossing patterns available for aluminum coils, including wood grain, hammer tone, and leather grain embossing. These patterns mimic the appearance of natural materials and are often used in interior design and architectural applications. The choice of embossing option depends on the specific requirements of the application and the desired aesthetic appeal. Manufacturers and customers can select the most suitable embossing pattern based on factors such as durability, texture, slip resistance, and overall design intent.

- Q: Are aluminum coils easy to bend and shape?

- Aluminum coils, being a malleable metal, can be easily bent and shaped. This characteristic makes them ideal for various shaping and forming tasks. Different techniques like rolling, bending, or pressing can be employed to manipulate aluminum coils, making them applicable in industries such as construction, automotive, and manufacturing. However, the ease of bending and shaping may vary depending on the specific alloy and thickness of the coil. Thicker coils may necessitate more force and specialized equipment, and different alloys may exhibit varying levels of malleability. In conclusion, aluminum coils present a versatile and relatively uncomplicated material for bending and shaping purposes.

- Q: How do aluminum coils contribute to noise reduction in buildings?

- Aluminum coils contribute to noise reduction in buildings through their ability to dampen and absorb sound waves. The coil's structure and material properties help to minimize the transmission of airborne noise, preventing it from entering or exiting a building.

- Q: i know that your not suppose to use DC for aluminum only with AC but is it possible?

- I know you need a different tungsten but i don't remember the ac dc part

Send your message to us

Aca Aluminum Coil Anodizing Corp Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords