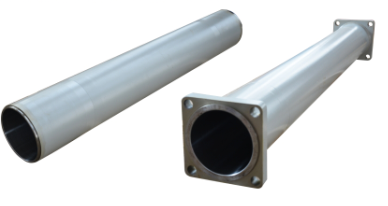

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1787MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN200*1787

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

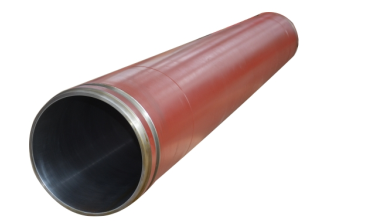

Concrete Pump Delivery Cylinder DN200*1787

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: Are there any specific guidelines for the installation of sensors or transmitters in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of sensors or transmitters in concrete pump spare parts. These guidelines typically include ensuring proper alignment and positioning of the sensors or transmitters, securely mounting them to prevent movement or damage, and following manufacturer instructions for wiring and connection. It is important to adhere to these guidelines to ensure accurate and reliable operation of the sensors or transmitters in concrete pump spare parts.

- Q: What are the potential risks of using non-standard or modified hydraulic components in concrete pump spare parts?

- Using non-standard or modified hydraulic components in concrete pump spare parts can pose several potential risks. Firstly, non-standard components may not have undergone the same rigorous testing and quality control as the original equipment manufacturer (OEM) parts. This means that their performance and durability may be compromised, leading to potential failures or malfunctions. Such failures can result in accidents, injuries, or damage to the equipment or surrounding structures. Secondly, using non-standard or modified components may void the warranty of the concrete pump and its spare parts. Manufacturers typically offer warranties to ensure the reliability and safety of their products. By using non-standard components, the warranty may become null and void, leaving the user responsible for any repairs or replacements needed due to issues arising from these non-standard parts. Another risk is the potential compatibility issues that may arise when using non-standard or modified components. Hydraulic systems rely on precise engineering and compatibility between various components to function optimally. Non-standard or modified parts may not fit properly or may have different specifications, leading to leaks, pressure imbalances, or reduced overall performance. Furthermore, the use of non-standard or modified components may also impact the overall efficiency and productivity of the concrete pump. OEM parts are designed to work seamlessly with the rest of the system, ensuring smooth operation and maximum output. By using non-standard parts, the performance of the pump may be compromised, resulting in increased downtime, decreased productivity, and higher maintenance costs. Lastly, the use of non-standard or modified components may also have legal and regulatory implications. In some jurisdictions, there may be regulations or standards in place that require the use of OEM or certified parts for certain equipment, including concrete pumps. Failure to comply with these regulations can result in fines, penalties, or legal liabilities in case of accidents or failures. In conclusion, the potential risks of using non-standard or modified hydraulic components in concrete pump spare parts include compromised performance and durability, warranty voidance, compatibility issues, reduced efficiency, and legal and regulatory implications. It is always advisable to use OEM or certified spare parts to ensure the safety, reliability, and optimal performance of the equipment.

- Q: What are the signs of a damaged concrete pump accumulator?

- There are several signs that indicate a damaged concrete pump accumulator. One of the most common signs is a decrease in the pumping efficiency. If you notice that the concrete pump is not able to pump the concrete as effectively as it used to, it could be a sign of a damaged accumulator. Another sign is a decrease in the pressure of the concrete being pumped. If you notice that the pressure is not as strong as before, or if there are sudden drops in pressure during pumping, it could indicate a problem with the accumulator. Leaks around the accumulator are also indicative of damage. If you notice any fluid leaks around the accumulator, it could mean that the accumulator is damaged or the seals are worn out. This can result in a loss of pressure and inefficiency in pumping. Unusual noises coming from the concrete pump can also be a sign of a damaged accumulator. If you hear any strange noises, such as knocking or hissing sounds, it could be a result of a damaged accumulator. Lastly, if you observe any visible damage on the accumulator itself, such as cracks or dents, it is a clear sign of damage. These damages can compromise the integrity of the accumulator and affect its performance. In summary, signs of a damaged concrete pump accumulator include decreased pumping efficiency, decreased pressure, leaks, unusual noises, and visible damages. If you notice any of these signs, it is important to address the issue promptly to prevent further damage and ensure the smooth operation of the concrete pump.

- Q: How does a hopper agitator motor ensure consistent concrete mixing?

- A hopper agitator motor ensures consistent concrete mixing by providing a continuous and powerful agitation motion within the hopper. This motion helps to break up any clumps or aggregates in the concrete mix, ensuring that all components are evenly distributed. The consistent agitation also helps to prevent settling or segregation of the mixture, resulting in a uniform and well-mixed concrete batch.

- Q: How can a faulty gearbox affect the pump's performance?

- A faulty gearbox can significantly impact the performance of a pump. The gearbox is responsible for transmitting power from the motor to the pump, and any dysfunction in this component can lead to various issues. Firstly, a faulty gearbox can cause a decrease in the pump's efficiency. The gearbox is designed to regulate the speed and torque of the pump, ensuring that it operates at optimal levels. If the gearbox is faulty, it may not be able to provide the necessary power to the pump, resulting in reduced performance and lower efficiency. This can lead to increased energy consumption and decreased overall productivity. Additionally, a faulty gearbox can cause the pump to experience excessive vibration and noise. A properly functioning gearbox helps to absorb and distribute the forces generated during operation, reducing vibration and noise levels. However, if the gearbox is faulty, it may fail to dampen these forces adequately, resulting in increased vibrations and noise. This can not only affect the pump's performance but also lead to premature wear and tear of other components, further impacting its overall efficiency. Furthermore, a faulty gearbox can result in inconsistent flow rates and pressure fluctuations. The gearbox plays a crucial role in controlling the speed and output of the pump. If the gearbox is malfunctioning, it may not be able to maintain a consistent flow rate or pressure, leading to fluctuations in the pump's performance. Inconsistent flow rates can disrupt processes that rely on precise volumes or pressures, causing inefficiencies and potential damage to downstream equipment. In conclusion, a faulty gearbox can have a detrimental effect on the performance of a pump. It can lead to decreased efficiency, increased vibrations and noise, as well as inconsistent flow rates and pressure fluctuations. Therefore, regular maintenance and prompt repair or replacement of faulty gearboxes are essential to ensure the optimal functioning of pumps and prevent any further damage or operational issues.

- Q: How can I minimize downtime during the replacement of concrete pump spare parts?

- Careful planning and efficient execution are essential for minimizing downtime when replacing concrete pump spare parts. Here are several strategies that can assist in achieving this goal: 1. Proactive maintenance: Establish a regular maintenance schedule to identify and replace worn-out parts before they malfunction. Regularly inspecting the concrete pump and its components can prevent unexpected breakdowns and reduce downtime. 2. Maintain spare parts inventory: Keep a stock of commonly needed spare parts, such as seals, filters, and hoses. This will significantly reduce the time spent on sourcing and ordering parts when a breakdown occurs. 3. Collaborate with dependable suppliers: Build relationships with reliable suppliers who can quickly provide high-quality spare parts. This ensures prompt access to the necessary components, minimizing delivery waiting time. 4. Train your team: Provide training to your maintenance and operational staff on efficiently identifying, troubleshooting, and replacing concrete pump spare parts. Equipping your team with the necessary skills enables them to promptly address issues, reducing overall downtime. 5. Schedule maintenance during low-demand periods: Plan maintenance and spare part replacement during periods of reduced demand or downtime. This could include weekends, holidays, or slower construction phases. Strategically scheduling the work ensures minimal impact on ongoing projects. 6. Optimize workflow: Identify areas causing delays or bottlenecks in your maintenance process. Seek opportunities to improve efficiency, such as optimizing the arrangement of spare parts, tools, and equipment, or implementing standardized repair and replacement procedures. 7. Utilize technology: Leverage technology to monitor the performance and condition of your concrete pump. Implementing a condition monitoring system can detect early signs of potential failures, allowing for proactive maintenance and part replacement. By implementing these strategies, you can minimize downtime during concrete pump spare part replacements, ensuring uninterrupted operations and maximizing productivity.

- Q: How can one determine the correct size and dimensions of concrete pump spare parts?

- To determine the correct size and dimensions of concrete pump spare parts, there are several important steps to follow: 1. Identify the specific make and model of your concrete pump: Each concrete pump has its own unique specifications and requirements for spare parts. Therefore, it is crucial to know the make and model of your pump before ordering any spare parts. 2. Consult the manufacturer's documentation: Manufacturers often provide detailed documentation that includes information on the required size and dimensions of spare parts. This documentation may include technical drawings, diagrams, and part numbers that can help you find the correct size. 3. Measure the existing spare part: If you already have a spare part that needs replacement, you can measure its size and dimensions using precision tools like calipers or a measuring tape. Take accurate measurements of key dimensions such as length, width, height, and any other relevant specifications. 4. Seek professional assistance: If you are unsure about the correct size and dimensions, it is advisable to consult with a professional or an authorized dealer. They have expertise in concrete pumps and can guide you in selecting the right spare parts based on your pump's specifications. 5. Consider compatibility and quality: When purchasing spare parts, ensure they are compatible with your concrete pump's make and model. Additionally, prioritize quality to ensure longevity and optimal performance. Buying from reputable suppliers or directly from the manufacturer can help ensure the spare parts meet the necessary size, dimensions, and quality standards. By following these steps, you can accurately determine the correct size and dimensions of concrete pump spare parts, ensuring smooth operation and minimizing downtime.

- Q: How does a concrete pump piston work?

- A concrete pump piston works by creating a reciprocating motion that pushes the concrete through the pump and into the desired location. The piston is a cylindrical component that fits snugly inside a cylinder. It is connected to a rod, which is attached to a hydraulic system. When the hydraulic system is activated, it pushes the rod forward, causing the piston to move in the same direction. As the piston moves forward, it creates a vacuum behind it, drawing the concrete into the cylinder through an inlet valve. Once the piston reaches the end of its forward stroke, the hydraulic system reverses its direction, pulling the rod back and causing the piston to move backward. This closes the inlet valve and opens an outlet valve, allowing the concrete to be forced out of the cylinder and into the delivery line. The reciprocating motion of the piston, along with the alternating opening and closing of the inlet and outlet valves, allows for a continuous flow of concrete through the pump. This process is repeated rapidly, allowing for efficient and consistent pumping of concrete to the desired location.

- Q: How do I ensure the compatibility of mechanical components in concrete pump spare parts?

- To ensure the compatibility of mechanical components in concrete pump spare parts, there are several key steps you can follow: 1. Identify the specific make and model of your concrete pump: Different concrete pumps may have varying designs and specifications, so it is crucial to know the exact make and model of your pump. This information will help you determine the compatible spare parts for your specific pump. 2. Consult the manufacturer's documentation: Review the manufacturer's documentation, including the user manual and parts catalog, to understand the recommended spare parts for your concrete pump. These documents often provide detailed information on the compatibility of various mechanical components. 3. Seek advice from the manufacturer or authorized dealers: If you are unsure about the compatibility of certain mechanical components, it is best to reach out to the manufacturer or authorized dealers. They have extensive knowledge and experience with their products and can provide guidance on selecting compatible spare parts. 4. Consider OEM (Original Equipment Manufacturer) parts: OEM parts are specifically designed and manufactured by the original equipment manufacturer. Using OEM parts ensures the highest level of compatibility and reliability. While they may be slightly more expensive than aftermarket alternatives, they often provide better performance and longer service life. 5. Check for standardized sizing and specifications: Mechanical components, such as seals, gaskets, and bearings, often have standardized sizes and specifications. Verify that the spare parts you are considering match these standardized measurements to ensure compatibility. 6. Conduct thorough research and comparison: Before purchasing spare parts, research different suppliers and compare their offerings. Look for reputable suppliers who specialize in concrete pump spare parts and have a track record of delivering high-quality, compatible components. 7. Perform compatibility tests: If you are uncertain about the compatibility of a particular mechanical component, consider conducting compatibility tests. This can involve installing the spare part in your concrete pump and verifying its fit, function, and performance. If possible, consult with a qualified mechanic or technician to assist you in conducting these tests. By following these steps, you can ensure the compatibility of mechanical components in concrete pump spare parts, minimizing the risk of compatibility issues and ensuring the smooth operation and maintenance of your concrete pump.

- Q: What is the function of a concrete pump hopper grate clamp?

- A concrete pump hopper grate clamp is designed to securely hold the grate in place on the hopper, preventing it from shifting or becoming dislodged during the concrete pumping process.

Send your message to us

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1787MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords