pu exterior wall panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

exterior siding panels

heat and cold insulation fire-safe

ISO9001:2008

International CE

Gost R certific

stone wall panel polyurethane Project Details:

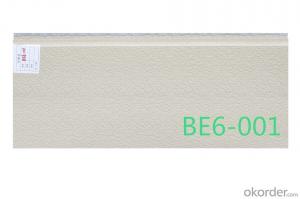

Product Name.: | sandwich decoration material |

HS Code: | 73089000 |

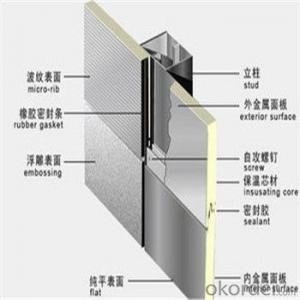

Material: | CNBM Panel is made up of three layers: the top material is embossed metal board coated with Alu-zinc, the middle is fire-safe material and Polyurethane foaming and the back is glass fibre paper |

Feature: | Decoration, insulation, energy-saving, fire-safe , easy installation, etc. |

Application: | CNBM Decorative Wall Panel could be used on any structural buildings : brick wall, steel structure, cement wall,, wood wall etc for decoration and insulation . |

Weight.: | 3.7kg/ m2 |

Panel Size: | Length :3000-6000mm(standard length is 3800mm) width: 380mm, thickness : 16mm |

Packing Size: | 3840*415*135mm |

Package quantity: | 8 pcs/carton |

Productivity: | 3000m2/ day |

Delivery period: | 3-7days |

Minimum Order: | 1000m2 ( 300m2 for one color ) |

Unit Price: | USD14-18/ Square Meter |

Shipment Terms: | FOB CRF CIF etc |

Payment Terms: | L/C, T/T |

Export Markets: | Middle East, Europe , South America ,Asia etc. |

Certificate : | CE, ISO9001:2008 , Gost R certification and Russia Fire-safe certification |

- Q: Color steel plate, color steel sandwich panels, clean color steel plate is the same thing? How much is the price?

- No, the difference is bigger. It is best to contact manufacturers directly

- Q: Sandwich composite panel and color steel tile difference which the high cost

- Sandwich panels are also called Caigang sandwich panels, is the middle of two-layer steel plate plus polyurethane foam or rock wool building plate; color steel tile is a single layer of pressure plate. Sandwich panels are more expensive.

- Q: What is the elastic modulus of the polyurethane sandwich panel?

- Inside and outside the steel plate, the middle is polyurethane, sandwich panel sandwich core elastic modulus is 6.5Mpa, inside and outside the steel plate is 205500Mpa

- Q: I would like to ask the color steel tile sandwich panels can cover the chicken coop? Does it have a good insulation effect?

- Can be, but the traditional ceiling color steel tile sandwich panels generally composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K ) Above, plus foam and foam board between the gap, the temperature is very serious, comprehensive actual thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because the polyurethane in the construction of the use of direct spray molding technology, so that the polyurethane foam layer without patchwork as a whole to form a complete impermeability, fundamentally put an end to the possibility of deep water along the seam along the seam. Which play a preservative and waterproof effect.

- Q: We want to build the activities of the board room is used as a dormitory, what materials used sandwich board good? What is the price of polystyrene board and rock wool board? As a dormitory board room in the height of the national standard? How high should it be?

- Mainly to see the use of activities, fire or rock wool sandwich board is good

- Q: Linhai 5 cm thick rock wool sandwich panels how many square

- You need the thickness of the steel plate is how much inside and outside the two steel plate, the middle is 5 cm rock wool. The thickness of the steel plate is generally 0.4mm-0.7mm color coated plate, rock wool capacity is not the same price is different, the industry generally use 80-120KG per cubic rock wool. High quality good point of the general price to ex-factory price of 85 or more.

- Q: I need to install a circuit breaker and a few outlets on a container made with sandwich panels.Are there any special equipments or materials for the job?

- This is a tough one. You may have to use 2X4's to extend the wall inwards to allow for it. I attached a link that might help.

- Q: in a sandwich panels is there a formula to calculate the amount of foam in the square meter?

- V =1*t where t is the thickness of the foam in meters.

- Q: Thickness of rock plate sandwich panels Drawings are written on the F50 color steel rock wool sandwich panels, I would like to ask F50 is the meaning of God, can represent the thickness of it? I asked whether the F50 can represent the thickness of 50 or just a model, in fact, the thickness of 100?

- I have a solution to it. F that Fire, should be the brand is Lokewei it, because Lokowei have 50F and 50C, there are 75F and 75C models, F is the fire board, C said the ordinary version, but 50 can not represent the thickness, because our Offer range, 50F and 50C have 50,80,100,120 mm ... and so the thickness, so 50 can not be the thickness of the thickness of the need for additional set. PS: 50 in Lokovo and intensity (density) have a relationship .50 strength is not high strength of 75. The higher the thickness the thicker the thickness

- Q: Is the interior material of the rock wool sandwich panel fluffy or compact?

- This is related to bulk density. Big enough to be dense, you can knock to listen to its voice.

Send your message to us

pu exterior wall panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords