Protection Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

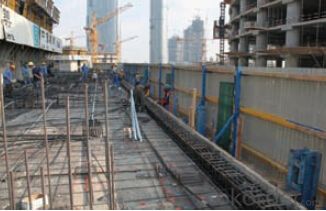

Protection Platform PP-50

A kind of new type construction protection system, applying operating platform and safer job

location for construction corps.

Characteristics:

◆ Easy and quick assembling.

◆ Lifted as a group, it is rapid and economic.

◆ Auto-climbing

◆ A safe and reliable anchor system

1. Composition

2. Assembly process of anchor system

(1) Embed V-climbing cone and anchor plate into the slab.

(2) Fix anchor shoe on the slab by tensile bolt.

(3) The fixed anchor shoe.

◆ High work efficiency with work platform and unload platform

◆ High light transmittance with the hollow block

- Q: What are the different safety training requirements for steel formwork installation?

- The different safety training requirements for steel formwork installation typically include proper use and handling of equipment, knowledge of safety protocols and procedures, understanding of personal protective equipment (PPE), awareness of potential hazards and how to mitigate them, and training on emergency response and evacuation procedures. Additionally, workers may need to undergo specific training related to fall protection, scaffolding, and other specialized tasks involved in steel formwork installation.

- Q: What are the different types of formwork clamps used in steel formwork?

- There are several types of formwork clamps that are commonly used in steel formwork construction. These clamps are designed to securely hold the formwork panels together, ensuring stability and accuracy during the concrete pouring process. 1. Wedge Clamps: Wedge clamps are one of the most commonly used formwork clamps. These clamps consist of a wedge-shaped piece that is inserted into a slot on the formwork panel. As the wedge is driven further into the slot, it creates a tight and secure connection between the panels. 2. Rapid Clamps: Rapid clamps are a type of formwork clamp that allows for quick and easy installation and removal. They are designed with a spring-loaded mechanism that allows the clamp to be easily tightened or loosened with minimal effort. 3. Turnbuckle Clamps: Turnbuckle clamps are adjustable clamps that are used to provide additional tension and support to the formwork panels. These clamps consist of a threaded rod with a turnbuckle mechanism that can be tightened or loosened to adjust the tension on the formwork. 4. Pipe Clamps: Pipe clamps are a type of formwork clamp that uses pipes or tubes to connect and secure the formwork panels. These clamps typically consist of a U-shaped bracket that is attached to the formwork panel and a pipe or tube that is inserted into the bracket to hold the panels together. 5. Panel Clamps: Panel clamps are specifically designed to hold large formwork panels together. These clamps typically consist of a large, heavy-duty clamp that can be tightened or loosened to securely hold the panels in place. Each type of formwork clamp has its own unique features and advantages, and the choice of clamp will depend on factors such as the size and weight of the formwork panels, the desired level of stability, and the specific requirements of the construction project.

- Q: What are the different types of formwork ties used in steel formwork?

- Some of the different types of formwork ties used in steel formwork include snap ties, wedge ties, coil ties, and flat ties. These ties are used to secure the formwork panels together and provide stability during the concrete pouring process.

- Q: How does steel formwork handle surface imperfections in concrete?

- Steel formwork is a rigid and durable material that is able to handle surface imperfections in concrete effectively. Its strength and stability allow it to support the weight of wet concrete, preventing any deformation or distortion caused by uneven surfaces. Additionally, steel formwork provides a smooth and uniform surface, minimizing any irregularities or blemishes that may occur during the pouring and curing process of concrete. Overall, steel formwork offers excellent resistance to surface imperfections, resulting in high-quality and aesthetically pleasing concrete finishes.

- Q: What is the expected lifespan of steel formwork ties?

- Several factors, including the quality of the steel, usage conditions, and maintenance, can influence the lifespan of steel formwork ties. Generally, these ties are designed to have a long lifespan and can be reused multiple times. When high-quality steel formwork ties are used in appropriate conditions and properly maintained, they can endure for several years. By regularly cleaning, inspecting, and maintaining them, they can be reused for multiple construction projects, thereby reducing costs and waste. It is essential to note that steel formwork ties may deteriorate over time, especially when exposed to harsh environmental conditions or corrosive substances. Therefore, it is crucial to regularly inspect the ties for any signs of damage or corrosion and replace them if necessary. Additionally, proper storage and handling of the ties when not in use can also contribute to extending their lifespan. In conclusion, the lifespan of steel formwork ties is not fixed, but with proper maintenance and care, they can last for several years and be reused multiple times. This makes them a cost-effective and sustainable choice for construction projects.

- Q: What are the different types of formwork spacers used in steel formwork?

- Various types of formwork spacers are commonly utilized in steel formwork. These spacers play a crucial role in maintaining the desired spacing between the formwork and reinforcement, thus ensuring the structural integrity of the concrete structure. Here, we present a range of formwork spacers frequently employed in steel formwork: 1. Plastic Spacers: Due to their lightweight nature, durability, and easy installation, plastic spacers are extensively employed in steel formwork. They are typically crafted from top-notch plastic materials and come in diverse shapes and sizes to accommodate different reinforcement requirements. 2. Steel Spacers: Steel spacers are another prevalent type of formwork spacer used in steel formwork applications. Constructed from high-strength steel, they possess the capacity to withstand heavier loads. Steel spacers prove ideal for heavy-duty applications that necessitate added strength and durability. 3. Rubber Spacers: In steel formwork, rubber spacers are employed to provide a cushioning effect and prevent direct contact between the reinforcement and the formwork. These spacers are suitable for scenarios where vibration or movement is anticipated, as they efficiently absorb shocks and minimize the risk of damage. 4. Concrete Spacers: Concrete spacers primarily find utility in precast concrete applications. Comprised of concrete, they act as support structures, ensuring the correct spacing between the formwork and reinforcement is maintained. Concrete spacers are not only durable and easy to install but also offer exceptional stability during the casting process. 5. Combination Spacers: Combination spacers are versatile in nature, incorporating various materials such as plastic and steel to provide enhanced strength and stability. These spacers are designed to meet specific project requirements and offer a cost-effective solution for various steel formwork applications. To guarantee optimal performance and safety, it is imperative to select the appropriate formwork spacer type based on the project's specific requirements, encompassing load capacity, spacing needs, and environmental conditions. Seeking guidance from a structural engineer or construction professional can ensure the correct selection and installation of formwork spacers.

- Q: How does steel formwork handle different concrete curing temperatures?

- Steel formwork is an incredibly durable and flexible construction material that is ideal for managing various concrete curing temperatures. Its main advantage lies in its ability to endure high temperatures without warping or causing structural damage. The concrete curing temperature can differ based on numerous factors, such as the weather, project requirements, and construction timetable. Steel formwork is specifically designed to withstand these differences and maintain its structural integrity throughout the curing process. When the concrete curing temperature is high, steel formwork effectively disperses the heat thanks to its exceptional thermal conductivity. This prevents excessive heat accumulation, which could lead to premature curing or thermal cracking of the concrete. The steel formwork acts as a heat absorber, evenly absorbing and distributing the heat to ensure consistent curing throughout the concrete structure. On the other hand, steel formwork also performs well in low-temperature curing conditions. Its high tensile strength and rigidity allow it to withstand the pressure exerted by the cold concrete mixture during curing. This prevents any distortion or warping of the formwork, ensuring precise shaping of the concrete structure. Furthermore, steel formwork is resistant to moisture and humidity, which are crucial factors in concrete curing. It does not absorb water or release moisture, maintaining a steady moisture content in the concrete during the curing process. This is particularly advantageous in areas with high humidity or when the curing time is prolonged. In conclusion, steel formwork is a dependable and sturdy material that can effectively handle various concrete curing temperatures. Its ability to disperse heat, endure cold temperatures, and resist moisture makes it the preferred choice for construction projects where temperature variations are a concern.

- Q: How does steel formwork handle formwork alignment and leveling?

- Steel formwork is a highly efficient and versatile system that excels in handling formwork alignment and leveling. It offers several features and mechanisms that ensure precise and accurate formwork placement. Firstly, steel formwork is known for its robustness and rigidity, which allows it to maintain its shape and dimensions during the pouring and curing of concrete. This inherent stability ensures that the formwork remains aligned and level throughout the construction process. In addition, steel formwork often incorporates adjustable components such as screws, wedges, and clamps. These elements enable fine-tuning of the formwork's position and elevation, allowing for precise alignment and leveling. By simply adjusting these components, workers can easily correct any deviations and ensure that the formwork is perfectly aligned. Furthermore, steel formwork systems often utilize integrated leveling systems. These systems typically consist of hydraulic jacks or mechanical devices that provide controlled and precise leveling. By utilizing these mechanisms, workers can easily adjust the formwork's height and maintain a consistent level across the entire structure. Moreover, steel formwork is capable of withstanding significant loads and pressures exerted by the concrete during pouring. This strength allows it to resist any deformation or deflection, ensuring that the formwork remains aligned and level even under challenging conditions. Overall, steel formwork offers exceptional capabilities in handling formwork alignment and leveling. Its inherent stability, adjustable components, integrated leveling systems, and strength make it a reliable choice for maintaining the desired accuracy and precision during concrete construction projects.

- Q: Can steel formwork be used for water retaining structures?

- Water retaining structures can indeed utilize steel formwork. One of the notable characteristics of steel formwork is its strength, durability, and ability to withstand high pressures. When designed and constructed correctly, steel formwork can establish a watertight seal and effectively resist the hydrostatic pressure exerted by water. Moreover, steel formwork facilitates a uniform and smooth finish, minimizing the chances of water leakage. However, it is crucial to implement appropriate waterproofing measures, including the use of suitable sealing materials and techniques, to prevent potential water leakage or seepage through joints or connections. Consistent inspection and maintenance are also indispensable to ensure the long-term integrity of the water retaining structure.

- Q: How does steel formwork handle form release agents?

- Compared to other types of formwork, such as wood or plastic, steel formwork has a different way of dealing with form release agents. The surfaces of steel formwork are typically smooth and non-porous, which makes it easier to apply and spread form release agents evenly. Before pouring concrete, form release agents are substances that are applied to the surfaces of the formwork. Their main purpose is to prevent the concrete from sticking to the formwork, making it easier to remove the formwork once the concrete has hardened. Steel formwork provides an excellent surface for applying form release agents. The smooth and non-absorbent nature of steel allows the release agent to create a thin film or coating on the surface, ensuring a clean separation between the concrete and the formwork. To properly apply form release agents on steel formwork, it is important to follow the instructions provided by the manufacturer. Typically, a sprayer or brush is used to evenly distribute the release agent onto the steel surface. It is crucial to apply enough release agent to ensure complete coverage, as insufficient application may result in the concrete sticking to the formwork. One advantage of steel formwork is its reusability, which means that form release agents need to be reapplied for each use. Once the concrete has set, the formwork can be easily removed, and any remaining form release agent can be cleaned off the steel surface. This allows the formwork to be used multiple times, saving costs and improving efficiency in construction projects. In conclusion, steel formwork effectively handles form release agents due to its smooth and non-porous surface. The even application of form release agents on steel formwork ensures a clean separation between the concrete and the formwork, making it easier to remove after the concrete has hardened. The reusability of steel formwork also allows for multiple applications of form release agents, reducing costs and improving efficiency in construction projects.

Send your message to us

Protection Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords