Professional 310s 309s 904l Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

316 stainless steel, 18Cr-12Ni-2.5Mo because adding Mo, so the corrosion resistance, weather resistance and high temperature strength in particular, in the harshness of the conditions of use

316L stainless steel containing molybdenum species, the steel containing molybdenum, the overall performance is better than steel 310 and 304 stainless steel, high temperature conditions, 316L stainless steel also has good resistance to chloride corrosion performance, it is usually used in the marine environment.

| Artical | sus 316l cold rolled stainless steel dinner plate | ||||||

| Specification | 1000mm*2000mm,1219mm*2438mm or as your requirement | ||||||

| Surface | 2B | ||||||

| Type | plate | ||||||

| Thickness | 0.3mm-1mm,1.2mm,1.5mm,2mm,2.5mm,3mm-6mm or as customized | ||||||

| Mill | TISCO/ BAOSTEEL/ JISCO/ ZPSS | ||||||

| Packing | standard export packing | ||||||

| Payment terms | 1.30%T/T in advance, the balance against the B/L copy | ||||||

| 2.30%T/T in advance, the balance against the L/C at sight | |||||||

| 3.100%L/C at sight | |||||||

| Dilivery time | 1.10days after receving the deposit of T/T | ||||||

| 2.10days after receving the L/C original | |||||||

chemical properties

| Typical chemical composition | ||

| % | 316 | 316L |

| C | 0.8 | 0.03 |

| Mn | 2 | 2 |

| Si | 0.75 | 0.75 |

| P | 0.045 | 0.045 |

| S | 0.03 | 0.03 |

| Cr | 16.0-18.0 | 16.0-18.0 |

| Ni | 10.0-14.0 | 10.0-14.0 |

| Mo | 2.00-3.00 | 2.00-3.00 |

| N | 0.1 | 0.1 |

| Fe | - | - |

Pysical properties

Tensile strength σb (MPa) ≥ 520

Conditions yield strength σ0.2 (MPa) ≥ 205

Elongation δ5 (%) ≥ 40

Section shrinkage ψ (%) ≥ 60

Hardness: ≤ 187HB; ≤ 90HRB; ≤ 200HV

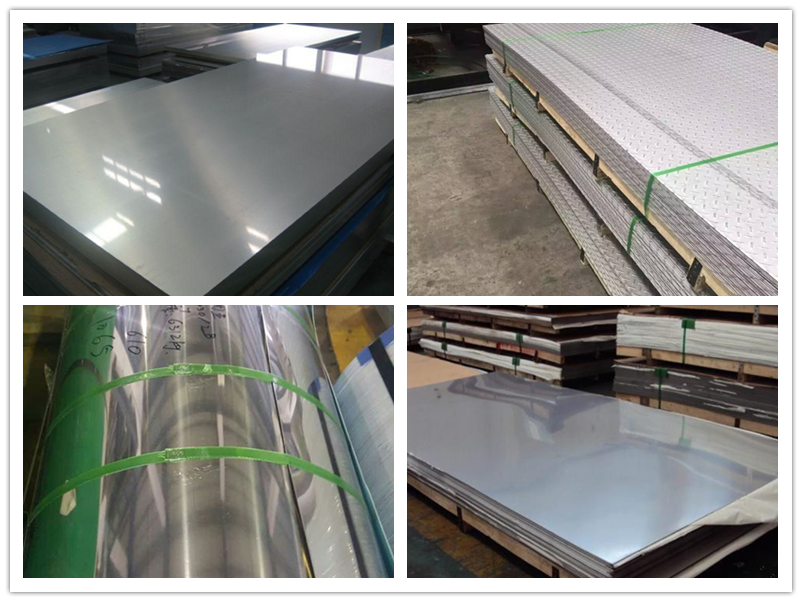

Detailed Images

Packaging & Shipping

Application

- Q: Can stainless steel sheets be used for pharmaceutical equipment?

- Yes, stainless steel sheets can be used for pharmaceutical equipment. Stainless steel is a preferred material for pharmaceutical equipment due to its excellent corrosion resistance, durability, and ease of cleaning. It is non-reactive and does not release any harmful substances that could contaminate the pharmaceutical products or affect their quality. Stainless steel sheets can be fabricated into various shapes and sizes to meet the specific requirements of pharmaceutical equipment such as storage tanks, mixing vessels, sterilization equipment, and piping systems. Moreover, stainless steel's smooth surface prevents the accumulation of bacteria, making it a hygienic choice for pharmaceutical applications.

- Q: What are the main chemical constituents of stainless steel plates?

- Stainless steel is often divided into martensitic steel, ferritic steel, austenitic steel, austenitic ferrite (duplex) stainless steel and precipitation hardening stainless steel according to the state of the organization. In addition, can be divided into components: chromium stainless steel, chromium nickel stainless steel and chromium, manganese, nitrogen, stainless steel and so on.

- Q: Are stainless steel sheets resistant to saltwater?

- Yes, stainless steel sheets are resistant to saltwater. Stainless steel is known for its corrosion resistance, and it is particularly well-suited for environments with high levels of saltwater exposure. The chromium content in stainless steel forms a protective layer on the surface of the metal, preventing rust and corrosion. This makes stainless steel sheets an excellent choice for applications in marine environments, such as boat construction, offshore structures, and coastal infrastructure. Additionally, stainless steel's resistance to saltwater also makes it suitable for other applications like coastal architecture, kitchen equipment, and medical instruments.

- Q: How do you straighten bent stainless steel sheets?

- To straighten bent stainless steel sheets, there are a few methods you can try depending on the severity of the bend. 1. Cold straightening: For slight bends, you can use a rubber mallet or a hammer to gently tap the bent area back into place. Start from the center of the bend and work your way towards the edges, applying gradual and even pressure. Be careful not to hit the stainless steel too hard, as it may cause further damage. 2. Heat straightening: If the bend is more severe, you can use heat to soften the stainless steel, making it easier to straighten. Start by heating the bent area using a blow torch or a heat gun. Once the stainless steel becomes red-hot, use pliers or a vice grip to carefully straighten the sheet. Keep in mind that this method should only be used for thicker stainless steel sheets, as thinner ones may warp or lose their shape if exposed to excessive heat. 3. Mechanical straightening: This method involves using specialized tools like a hydraulic press or a metal brake to apply controlled pressure and straighten the bent stainless steel sheet. This is recommended for large or heavy-duty sheets that cannot be easily straightened by hand. Ensure that you follow the manufacturer's instructions when using these tools to avoid any accidents. Remember to always wear appropriate safety gear, such as gloves and eye protection, when working with stainless steel sheets. If you are unsure or uncomfortable with straightening the sheets yourself, it is recommended to consult a professional metalworker or a fabrication shop for assistance.

- Q: Are stainless steel sheets suitable for food storage containers?

- Yes, stainless steel sheets are highly suitable for food storage containers. Stainless steel is a durable and non-reactive material that does not leach harmful chemicals into food. It is resistant to corrosion, easy to clean, and can maintain the freshness and quality of stored food for extended periods. Additionally, stainless steel is non-porous, preventing the absorption of odors or flavors.

- Q: What is the price range for stainless steel sheets?

- The price range for stainless steel sheets can vary depending on factors such as size, thickness, and grade of stainless steel. Generally, stainless steel sheets can range from $20 to $200 per sheet, but prices can be higher for specialized or custom-made sheets.

- Q: What is the impact resistance of stainless steel sheets?

- Stainless steel sheets have a high impact resistance due to their unique properties and composition. The impact resistance refers to the ability of a material to withstand sudden loads or forces without breaking or deforming permanently. Stainless steel sheets possess excellent toughness and durability, making them highly resistant to impact. The impact resistance of stainless steel sheets can be attributed to their high tensile strength and ductility. Stainless steel is an alloy that contains iron, chromium, and other elements, which impart its strength and corrosion resistance. The addition of chromium forms a protective oxide layer on the surface of the steel, preventing it from rusting or corroding easily. Furthermore, stainless steel sheets are available in various grades, each with its specific composition and properties. The most commonly used grade for impact-resistant applications is 304 stainless steel, which offers good resistance to impact and is widely used in industries such as construction, automotive, and aerospace. The impact resistance of stainless steel sheets also depends on their thickness. Thicker sheets tend to have higher impact resistance due to their increased mass and structural integrity. However, even thinner stainless steel sheets can still provide considerable impact resistance due to the inherent strength and toughness of the material. In practical applications, stainless steel sheets are often used in environments where impact resistance is critical, such as in the manufacturing of machinery, equipment, and structures subjected to high loads or potential impacts. They can withstand heavy impacts without cracking, fracturing, or deforming, thus ensuring the integrity and longevity of the finished product. Overall, stainless steel sheets possess an excellent impact resistance that makes them a preferred choice in various industries. Their high strength, corrosion resistance, and durability make them suitable for applications where resistance to impact is essential.

- Q: What drill can drill stainless steel?

- Drilling stainless steel materials, there are two main domestic products: high-speed steel bit, carbide drill. Carbide hollow drill is of high toughness and good wear resistance. It is recommended that you use this material. The price depends on the specifications you need.

- Q: What are the different shapes available for stainless steel sheets?

- Stainless steel sheets are available in various shapes, including flat sheets, perforated sheets, corrugated sheets, embossed sheets, and diamond plates. These shapes cater to different applications and aesthetic preferences in industries such as construction, automotive, and interior design.

- Q: Are stainless steel plates 3.4mm or 3.5mm thick?

- There are stainless steel sheets in these two specifications.According to standard GB/T 708-2006 cold rolled steel sheet size tolerances, the stainless steel sheet thickness is 0.3~4 mm,

Send your message to us

Professional 310s 309s 904l Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords