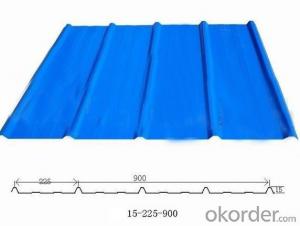

Prime Quality Galvanized Corrugated Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

corrugated steel sheet

Other relevant parts for cars or machines we are making in our workshop are as follows:

universal joint

tranmission shaft

steel structure

forge products

curtain rod and curtain accessory

Pls contact for more details.Give us a chance, you would get a reliable supplier.

corrugated steel sheet

It is a perfect exhibition on the industry of construction steel structure, and it is a perfect opportunity for you to enlarge your view, edify brightness and catch the market. We are looking forward to your coming.

· Invite object:

We will send 300,000 tickets and 50,000 business invitation

Invite the government persons in the ministry of construction, communications, railway Dep., National Development and Reform Commission, Science & Technology Dep. etc

Corrugated Steel Roofing Sheet

Features 1) Raw materials galvanized steel, galvanized pre-painted sheet and aluminum sheet 2) Corrugated sheets are formed by roll forming machines 3) Thickness and color can be different 4) Sizes 0.25 x 850mm - 1.2 x 920mm 5) Easy to install, high strength and lower costs 6) Widely used as walls or roofs for factories, warehouses, garages, exhibition centers and cinemas

- Q: What are the different types of steel coil finishing equipment?

- There are several types of steel coil finishing equipment, including slitting lines, cut-to-length lines, blanking lines, and coil coating lines. Slitting lines are used to cut large coils into smaller widths, while cut-to-length lines cut coils into specific lengths. Blanking lines are used to cut complex shapes out of coils, and coil coating lines apply a protective or decorative coating to the surface of the steel coil.

- Q: 2 refridgerator of similar model and same brand..one is stainless steel...the other is clear steel (cheaper)..so wat's the difference between the two?

- In okorder /... The appliances that are not made of stainless steel are made of a mild steel which is then finished with a durable enameled finish, in colors even. Stainless steel appliances look very nice in the showroom, but it is no fun trying to keep them fingerprint and handprint free. If you have ever owned a toaster that was made from stainless steel then you know how much fun it would be to have to keep a whole refrigerator fingerprint free, The oils transferred from the skin leave very distinct smears on stainless surfaces.

- Q: What are the different methods of testing the mechanical properties of steel coils?

- There are several methods for testing the mechanical properties of steel coils. Some commonly used methods include tensile testing, hardness testing, impact testing, and bend testing. Tensile testing measures the strength and ductility of the steel by applying a tensile force until it breaks. Hardness testing determines the resistance of the steel to indentation or scratching. Impact testing measures the ability of the steel to withstand sudden forces or shocks. Bend testing evaluates the flexibility and resistance to cracking of the steel by bending it to a specific angle. These methods help assess the quality and performance of steel coils in various applications.

- Q: What are the dimensions of steel coils used in the storage system industry?

- The dimensions of steel coils used in the storage system industry vary depending on the specific requirements of the storage system and the industry it is used in. However, common dimensions for steel coils used in storage systems can range from 0.15mm to 3.5mm in thickness, and from 600mm to 2100mm in width. The length of the coils can also vary, typically ranging from 1000mm to 6000mm.

- Q: Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or sunken designs on a material, and it can be applied to steel coils to add texture or decorative patterns.

- Q: What are the different surface finishes of steel coils?

- There are several different surface finishes of steel coils, including hot rolled, cold rolled, galvanized, and coated finishes. Hot rolled coils have a rough and textured surface, while cold rolled coils have a smoother and more refined surface. Galvanized coils are coated with a layer of zinc to protect against corrosion, while coated coils have additional layers of paint or other materials for aesthetic or functional purposes.

- Q: How do steel coils contribute to energy efficiency in lighting?

- Steel coils do not directly contribute to energy efficiency in lighting. Steel coils are typically used in the manufacturing of various electrical and electronic appliances, including lighting fixtures. However, the energy efficiency in lighting primarily depends on the type of light source used. The energy efficiency of lighting is typically determined by the type of light bulb or fixture used, such as incandescent, fluorescent, LED, or halogen. Each of these light sources has different energy consumption characteristics. Steel coils, on the other hand, are primarily used for structural support, heat dissipation, and protection in lighting fixtures. They are not directly involved in the energy efficiency of the lighting system. However, steel coils can indirectly contribute to energy efficiency in lighting by providing strong and durable support to the lighting fixtures. This allows for reliable and long-lasting installations, minimizing the need for frequent maintenance and replacements. A well-supported lighting system ensures optimal performance and reduces any energy wastage or inefficiencies that may arise from loose or unstable fixtures. Additionally, steel coils can also be utilized in the manufacturing of reflectors or housings for lighting fixtures, which can help enhance the overall efficiency and distribution of light. By effectively reflecting and directing the light output, the utilization of energy and illumination can be optimized, reducing any potential energy waste. While steel coils themselves do not directly impact the energy efficiency of lighting, their use in the construction and support of lighting fixtures can indirectly contribute to a more energy-efficient lighting system.

- Q: What are the common processing defects in steel coils?

- Steel manufacturers must identify and rectify the following processing defects commonly found in steel coils: 1. Coil breaks: These occur when the steel strip breaks during the process of winding the coil. Improper tension control or material defects can cause these breaks. 2. Slivers: Thin, elongated steel pieces get trapped in the coil during the rolling process. Foreign materials, scale, or defects in the rolling mill can cause slivers. 3. Edge cracks: Cracks appearing along the edges of the coil are known as edge cracks. Improper edge trimming, material defects, or excessive rolling forces can cause these cracks. 4. Surface defects: Scratches, pits, or scars on the steel coil constitute surface defects. Handling issues, improper cleaning, or rolling mill defects can cause such defects. 5. Coil set: Coil set refers to the coil's tendency to retain a curvature even after it has been uncoiled. This can occur due to uneven cooling during the rolling process or improper tension control. 6. Oil spots: Stains or discolorations on the steel coil caused by residual oil or lubricants are known as oil spots. Inadequate cleaning or incorrect lubricant application can lead to oil spots. 7. Wavy edges: Irregularities or waves along the edges of the steel coil are referred to as wavy edges. Uneven rolling forces or improper edge trimming can cause these irregularities. 8. Lamination: Lamination defects occur when layers or sheets of steel are not properly bonded together. Material defects or improper rolling conditions can cause lamination defects. 9. Burr: A raised edge or roughness along the edge of the steel coil is called a burr. Improper trimming or cutting processes can cause burrs. 10. Non-uniform thickness: Non-uniform thickness refers to variations in the thickness of the steel coil. Uneven rolling forces, improper cooling, or material defects can cause non-uniform thickness. Identifying and addressing these processing defects is crucial for steel manufacturers to ensure the quality and reliability of their steel coils.

- Q: The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- Damascus steel is the poorest quality. The laminations separate under stress. Centuries ago the only way to get steel bars was to make it up by hammering wires together in a series of welds. The welds usually were porous and the steel would fail. The pattern of the welds is attractive to some people. An old file has good hard steel and wiill make up into a knife if it is annealed to make it easier to shape and cut. The hardness can be restored by tempering. Treating with oil is the cure to prevent rust.

- Q: Does Steel Cut Oatmeal have the same health benefits as Old Fashioned Oatmeal? What is the difference in processing?

- Steel Cut Oats Steel-cut oats are whole oat kernels cut into small chunks rather than being smashed flat as in oatmeal. This gives the oats more of a chew texture and also slows both cooking time and digestion time. That means that they have a lower glycemic index and are thus preferable for increasing satiety, lowering the insulin response to the meal, and keeping blood sugar levels from peaking. This also results in delaying hunger so a person is less likely to snack or get overly hungry before the next meal. Here is how I like to cook oats for breakfast. Ingredients 1/2 cup Dry steel cut oats 1 cup Water (You may want a little more than a cup, experiment to your liking) 2 T Raisins (optional or replace with chopped dried apricots etc.) 2 T Ground flax meal (optional, but high in healthy n-3 fatty acids and fiber) Salt to your taste (try Lite salt to lower sodium intake) 2T Sunflower seeds or almonds 1 cup Fresh berries or a banana Directions Heat water to a boil. While water is heating, add the salt, raisins, and flax meal. When the water boils, add the steel cut oats. Stir once. Turn heat down to simmer and cook covered for 7-8 minutes. Provides two small servings. Double for large servings or small servings for 4 people. Serve and eat while hot. Add soy milk or low fat milk. Slice fresh fruit on top to add extra flavor. My wife likes banana slices. I like fresh berries, peaches, or sugar free applesauce. For extra crunch sprinkle almonds or sunflower seeds on top.

Send your message to us

Prime Quality Galvanized Corrugated Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords