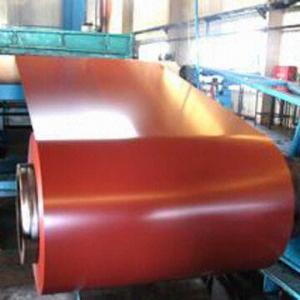

Pre-Painted Aluminum Coils Price, Roll

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (asmuch as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Features:

1. Excellent quality of products

2. Quick delivery

3. Best service to clients

4. BV,SGS avalible

5. No buckle o waveness

6. Tension leveling

7. Certificate of Origin

8. Form A,E

Packaging Detail: Carton ,Wooden pallet with plastic protection packing,standard seaworthy packing or as your request.

ProductionCapacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Coveredfactories with full production line

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

30 day after client’s deposit

- Q: Is it safe to use aluminum foil to wrap food for cooking purposes?

- <p>Yes, you can use aluminum foil to wrap food for cooking. Aluminum foil is commonly used for wrapping, baking, and cooking food in the oven, grill, or on the stovetop. It helps retain moisture, prevents food from sticking, and can be used to create a sealed environment for steaming or baking. However, it's important to avoid using aluminum foil at very high temperatures as it can react with acidic or alkaline foods and potentially leach aluminum into the food. Always follow the manufacturer's guidelines for safe use and cooking temperatures.</p>

- Q: the ingredient on the back says aluminum?also ..what is sodium benzoate?Is all this stuff that terrible for you? Or does it mean something else?

- The aluminum is in the baking powder. Very common but you can buy it without it, it is much healthier for you. Aluminum is correlated to Alzheimer's and ADD. Baked goods taste much better without the aluminum too. Benzoate of soda, a preservative that can alter your DNA. Not too good for you, no matter what the FDA may say about it. All told, if you are concerned for your health, keep to organic as much as possible and made from scratch too. Way too much junk is put in our food and health products.

- Q: why do we use copper more than aluminum? give some characteristic of copper that makes it better then aluminum?

- Copper is greater suitable than aluminum via fact it has a conductivity of ninety seven% whilst in comparison with sixty two % for aluminum.Copper is likewise and safer, via fact, its contacts whilst splicing will stay carrying out even for an prolonged time, mutually as in aluminum, splices especially if carried out copper to aluminum will oxidize after a era, ensuing to overheating and electric powered fires. Aluminum development wiring isn't yet allowed in lots of Asian cities.

- Q: This question asks for a comparison between aluminum coil and other types of wire, highlighting their differences.

- <p>Aluminum coil is a type of wire made from aluminum, known for its lightweight, high conductivity, and corrosion resistance. It's commonly used in electrical applications, construction, and packaging. Other types of wire, such as copper wire, have different properties. Copper, for instance, has higher conductivity than aluminum but is heavier and more expensive. Steel wire is stronger and more durable but less conductive and prone to rust. The choice between aluminum coil and other wires depends on the specific requirements of strength, conductivity, cost, and environmental resistance for the application in question.</p>

- Q: What are the different pre-treatment methods for aluminum coils?

- There are several different pre-treatment methods that can be used for aluminum coils. These methods are designed to prepare the surface of the coils for further processing or coating. One common pre-treatment method is degreasing. This involves removing any oils or greases that may be present on the surface of the aluminum coils. Degreasing can be done using solvents or alkaline cleaners, depending on the specific requirements of the application. Another pre-treatment method is etching. Etching is used to remove any surface oxides or contaminants that may be present on the aluminum coils. This process can be done using acidic solutions or with the help of mechanical methods such as sandblasting or brushing. Phosphating is another pre-treatment method that is commonly used for aluminum coils. Phosphating involves applying a phosphate coating to the surface of the coils. This coating helps to improve the adhesion of subsequent coatings or paints, as well as providing corrosion resistance. Conversion coating is also a popular pre-treatment method for aluminum coils. Conversion coatings are thin layers of inorganic compounds that are formed on the surface of the coils. These coatings improve the adhesion of subsequent coatings or paints, as well as providing corrosion resistance. Some common conversion coatings used for aluminum include chromate, chromate-free, or anodizing. In summary, the different pre-treatment methods for aluminum coils include degreasing, etching, phosphating, and conversion coating. Each method serves a specific purpose in preparing the surface of the coils for further processing or coating, and the choice of method will depend on the specific requirements of the application.

- Q: What are the different thicknesses available for aluminum coils?

- To meet different application needs, aluminum coils come in various thicknesses. The available options typically span from 0.2mm to 6mm. The thickness required depends on the intended use of the coil. For applications that prioritize flexibility and lightweight properties, thinner coils ranging from 0.2mm to 1mm are commonly used in electronics, packaging, and building materials. Medium thickness coils, ranging from 1mm to 3mm, find frequent use in automotive parts, roofing, and cladding applications. Conversely, heavier-duty industrial applications like shipbuilding, aerospace, and construction utilize thicker aluminum coils, measuring 3mm to 6mm in thickness. To determine the most suitable thickness for a given application, it is crucial to consider the specific requirements and intended use of the aluminum coil.

- Q: This question asks for a brief explanation of the process involved in the manufacturing of aluminum coils.

- <p>Aluminum coil is made through a series of processes starting with the melting of aluminum ingots or scrap. The molten aluminum is then poured into a casting machine where it's cooled and solidified into large slabs. These slabs are then heated and passed through a series of rolling mills to reduce their thickness and achieve the desired coil gauge. The rolling process is often hot or cold, depending on the final application of the coil. After rolling, the aluminum is coiled into rolls and may undergo additional treatments like annealing to improve its properties. Finally, the aluminum coil is cleaned, inspected, and shipped for use in various industries such as construction, automotive, and packaging.</p>

- Q: What are the different surface textures available for aluminum coils?

- There are several different surface textures available for aluminum coils, each with its own unique characteristics and applications. 1. Smooth: Smooth surface texture is the most basic and common type of finish for aluminum coils. It has a sleek and polished appearance, making it suitable for a wide range of applications such as architectural cladding, signage, and consumer electronics. 2. Stucco: Stucco texture features a raised pattern resembling small pebbles. This texture is achieved by embossing the surface of the aluminum coil, providing enhanced durability and resistance to scratches and dents. It is often used in applications where a more robust and decorative finish is desired, such as roofing, wall panels, and decorative trim. 3. Diamond: Diamond texture features a diamond-shaped pattern embossed onto the surface of the aluminum coil. This texture not only enhances the aesthetic appeal but also provides additional traction and slip resistance, making it ideal for applications such as flooring, stairs, and ramps. 4. Brushed: Brushed texture is achieved by mechanically brushing the surface of the aluminum coil, creating a linear pattern. This finish gives the aluminum a distinctive, satin-like appearance, making it popular for architectural applications such as interior wall cladding, furniture, and decorative elements. 5. Hammered: Hammered texture is achieved by hammering the surface of the aluminum coil, resulting in a unique and irregular pattern. This texture provides a rustic, handcrafted look, making it suitable for applications such as decorative accents, light fixtures, and furniture. 6. Perforated: Perforated texture involves creating a pattern of small holes or perforations on the surface of the aluminum coil. This texture allows for increased airflow, light transmission, and sound absorption, making it commonly used in applications such as ventilation systems, acoustic panels, and decorative screens. These are just a few examples of the various surface textures available for aluminum coils. The choice of texture depends on the specific requirements of the application, including aesthetics, functionality, and durability.

- Q: Domestic production of color coated aluminum coil manufacturers which good?

- Color coated aluminum coil has two kinds of polyester color coating and fluorocarbon coating.

- Q: What are the typical thickness tolerances for aluminum coils?

- The specific manufacturing standards and industry requirements play a role in determining the typical thickness tolerances of aluminum coils. Generally, the range of thickness tolerances for aluminum coils is between +/- 0.001 and 0.005 inches. These tolerances are crucial in maintaining the thickness of the aluminum coils within acceptable limits, ensuring they meet the desired specifications and applications. It should be emphasized that the intended use of the aluminum coils, whether for architectural, automotive, or aerospace purposes, may influence the specific tolerances.

Send your message to us

Pre-Painted Aluminum Coils Price, Roll

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords