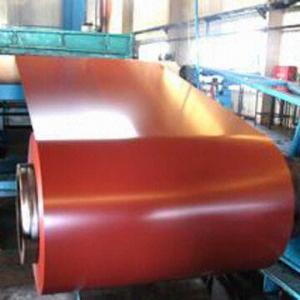

galvanized steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) Quality Standard & Grade: JIS G3302, SGCC / ASTM 653M CQ/ EN10142 DX51D+Z

2) Thikness tolerance: +/-0.02mm Width tolerance:+/0.02mm

3) Zinc coating weight: 50g/m2

4) WEIGHT OF PER COIL: 3-5MT

5)Technology: cold rolled

6) Surface of Product: regular spangle / big spangle/ small spangle; Surface Treatment: chromated , non oiled, skin passed

7) Packing: export standard packing,packed with moisture resistant paper and metal

wrapping,securely tied for export,on metal skids7) Country of Origin :

SIZE:0.18*762

- Q: Hello,is it possible to divide an alloy in its own elements? I am particularly interested in Stainless Steel, which is made of Nickel, Chrome and Iron. Do you have an idea of where can I find some more information (blogs, reviews, sites or books)?Thanks for your help

- Yes it is possible to recover individual elements from an alloy such as stainless steel, but not easy. Look up etching of stainless steel on google. This same etching solution will completely dissolve stainless steel. These solutions are strong acids such as H2SO4 and HNO3 so safety goggles and good ventilation are absolutely required. Once the metal has been dissolved, then you would need to use a qualitative analysis scheme to precipitate out the different metals one at a time as compounds, then do additional reactions to recover the metallic elements.

- Q: How are steel coils used in the production of kitchen appliances?

- Steel coils are used in the production of kitchen appliances as they are shaped, cut, and formed into various components such as bodies, doors, panels, and frames. These coils provide the necessary strength, durability, and stability required for the construction of kitchen appliances, ensuring the longevity and reliability of the finished products.

- Q: When steel is cast, does it become weaker/more brittle or anything of this nature? what are the side effects of steel casting on the steel itself?How can you correct these?

- It contains too many air bubble spacing and too many impurity that make it easily to be broken apart. Melt it down again with high heat to remove most impurity, after this process,it becomes iron.

- Q: I am working on a hydrogen generator, but the stainless steel I am using corrodes and turns the water brown. Can anyone tell me if there is stainless steel that does not corrode, and if so, what is it called and where can I get some.Thank you.

- Maybe okorder Hope this can help you.

- Q: How are steel coils used in the production of automotive exhaust systems?

- Steel coils are typically used in the production of automotive exhaust systems as they provide the necessary material for manufacturing exhaust pipes and components. The coils are often processed and shaped into the desired forms, such as tubes or mufflers, and then welded or fastened together to create the exhaust system. Steel coils are favored due to their durability, heat resistance, and ability to withstand the harsh conditions of exhaust gases, ensuring the longevity and efficiency of the automotive exhaust system.

- Q: Steel coil from vertical to horizontal, what sling needs?

- Consider using the function with hydraulic prop hanging clamp from the coil center will hold tight after hanging up, then put in a L type hydraulic turnover device platform or unilateral double column loading platform, then L platform can realize 90 degrees down, vertical horizontal variable.

- Q: What is the maximum diameter of a steel coil?

- The maximum diameter of a steel coil varies depending on the specific type and thickness of the steel, as well as the capabilities of the manufacturer's equipment. However, in general, steel coils can have diameters ranging from a few inches to several feet.

- Q: hey... i don't need to change my strings, but i found a set of Bronze acoustic guitar strings by pure tone... i have a few questions on them:can i put them on a steel string guitar? i know i can't put nylon strings on... but i don't see why i can't put bronzethey are light gauze... i have no idea what my current gauze is, but i play in Dropped D tuning... so would the E/D string (6th) be too loose? finally, can you get strings designed to be played in Drop D?any help is apprechiated :D

- I don't see why not. Put them on and try it out.

- Q: What are the different types of steel coatings for coil protection?

- There are several types of steel coatings for coil protection, including galvanized coatings, zinc coatings, aluminum coatings, and polymer coatings.

- Q: I'm going to see Man Of Steel this weekend, and the reviews that I've been hearing aren't that good. I've been hearing that it's this depressing, dark, dramatic film with no humor, loud noises, and action on top of action (which is kind of what I expected from this movie). With that said, I was quite positive that this was what the fans wanted, a more serious Super Man interpretation. I'm ultimately going to judge the movie when I see it, but for now, I have 3 short questions for you:1) What did you think of Man Of Steel?2) Superman Returns got somewhat better reviews than Man Of Steel. Does it seem logical?3) There is a huge fan battle between Man Of Steel and Christopher Reeve's version of Super Man. Which one do you favor?

- I loved the new interpretation in Man of Steel Superman Returns got very poor reviews in the beginning, and as the hatred has worn off and fans have been the only ones voting, the score has moved up. As fond as I am of Christopher Reeves, his version was a touch campy. I much prefer the serious treatment.

Send your message to us

galvanized steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords