Prime Hot Rolled Coil HR Steel Coil China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Introduction

Product name: Hot rolled steel coil Material:Q195,Q235,SS400,SM400(A.B),ST37-2,ST37-3,1010-1050,S235(JR.J0.J2G3.J2G4)

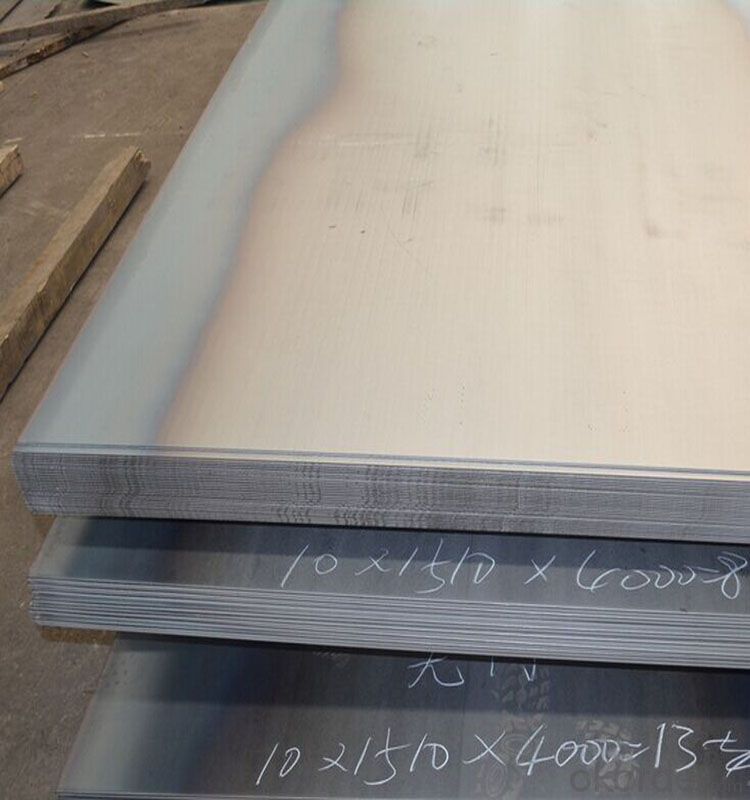

Thickness: 1.5-50mm

Width: 300-2500mm

Application: widely used in construction, household appliance, automobile, light industry, etc

Commodity | Hot rolled steel coil |

Technical Standard: | JIS,GB,DIN,BS,ASTM |

Grade | SS400,Q235,A36,ST-37 |

Width | 300mm to 2500mm |

Thickness | 1.5mm to 50mm |

Surface treatment | Oiled,anneals |

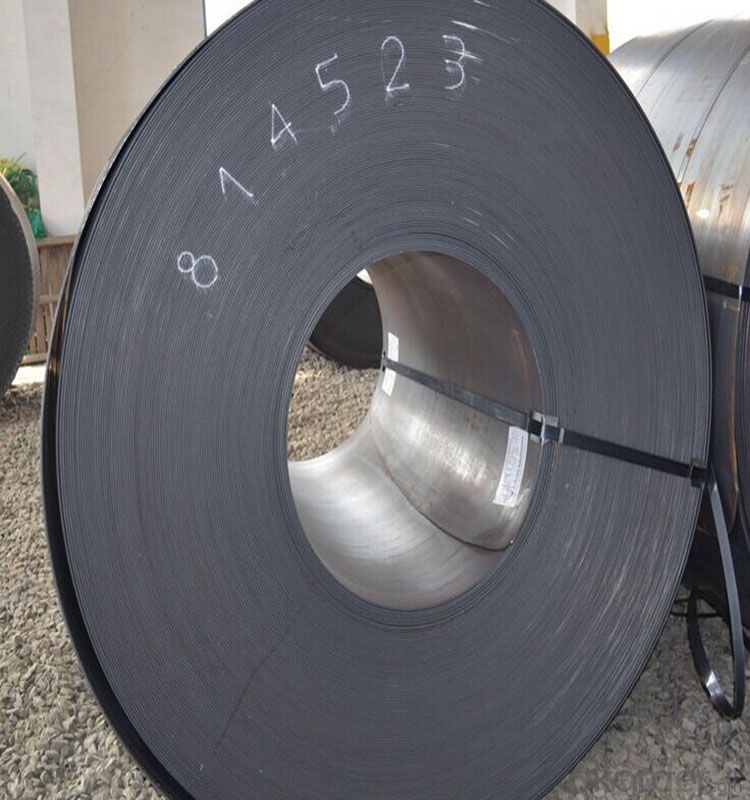

ID coil | 508mm or 610mm |

Coil weight | 3-10 tons as clients's requirements |

Thickness Tolerance | +/-0.15mm |

Width Tolerance | +/-3mm |

Price terms | FOB, CFR ,CIF, CNF ,DAP, etc |

Packaging Details: | Standard export packing or according to clients required |

delivery time | Within 15work days after deposit received. |

Payment Terms: | T/T Or L/C at sight |

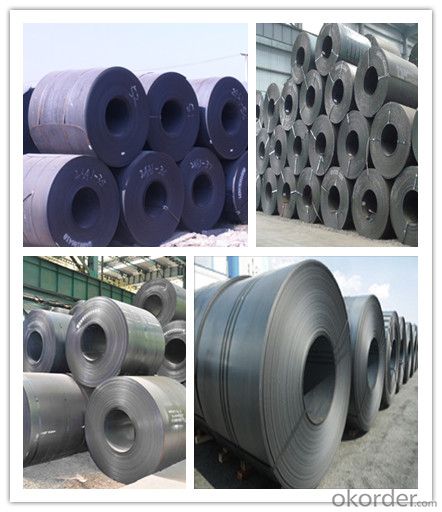

2.Product Photos

3.Service

- Q: How are steel coils used in the production of gutters and downspouts?

- Steel coils are used in the production of gutters and downspouts by being formed and shaped into the desired size and shape of the gutter or downspout. The coils are unwound and passed through a series of machines that bend, cut, and shape the steel into the necessary components. These components are then assembled and attached to create the final gutter or downspout, which provides effective drainage and protection for buildings.

- Q: I haven't seen Man of Steel yet, but which one do you think was better? (please no spoilers)

- Well, I haven't seen it Man of Steel but I really see it hard to believe that's better than Superman. To me, Superman with Christopher Reeve is the best movie about Superman ever made. When I first saw it I was amazed. Watching Superman flying for the first time, catching Loise and graving that helicopter before it falls... it was awesome! I loved it! The other movies that followed were bad but this one was amazing. I've seen what other actors have made with the character, but I believe Christopher was the best. He was the perfect man, the perfect gentleman and the best superhero ever. I know that this Superman is for the new generations so it will be more 'real' and more 'suffered' or will have more personal issues dealing with his origins and blah blah blah... and I wish him good luck, but honestly? I stick to the original Superman because whenever I see Christopher Reeve flying around the planet as Superman (hanging from wires-no CGI people!) and I hear that characteristic music I just melt and I'm a child once more. So good luck to the new generation, I really hope they like this new guy and new story, but I'm more than fine with the original version, thank you. Hope it helps! ;)

- Q: How are steel coils handled during loading and unloading?

- Steel coils are typically handled using specialized equipment such as cranes or forklifts during loading and unloading. They are carefully lifted, secured, and positioned onto trucks or storage areas. Safety measures are followed to prevent damage or accidents during the process.

- Q: How do steel coils contribute to the energy infrastructure sector?

- Steel coils play a vital role in the energy infrastructure sector by providing the necessary materials for the construction and maintenance of various energy-related structures and equipment. Firstly, steel coils are widely used in the production of pipelines, which are the lifelines of the energy industry. These pipelines transport oil, natural gas, and other energy resources over long distances, ensuring a steady supply to power plants and other energy facilities. Steel coils are used to manufacture seamless and welded pipes that possess high strength, durability, and resistance to corrosion, making them suitable for handling the harsh conditions of energy transportation. In addition to pipelines, steel coils are used in the production of storage tanks for oil, natural gas, and other fuels. These tanks are crucial for storing large quantities of energy resources, ensuring a continuous supply even during periods of high demand. Steel coils are utilized to fabricate the tank shells, providing the necessary strength and structural integrity to withstand the pressure and environmental factors associated with energy storage. Furthermore, steel coils are instrumental in the construction of power plants and other energy infrastructure facilities. They are used to manufacture structural components such as beams, columns, and supports, which provide the foundation and stability required for the safe operation of these facilities. Steel coils also contribute to the production of equipment such as turbines, generators, and transformers, which are essential for converting energy into usable forms and distributing it to end-users. Moreover, steel coils are utilized in the construction of transmission towers and electrical grids. These structures and networks are responsible for transmitting electricity from power plants to residential, commercial, and industrial consumers. Steel coils are used to manufacture the towers and poles that support high-voltage transmission lines, ensuring their stability and reliability in transmitting electricity over long distances. In summary, steel coils are indispensable in the energy infrastructure sector as they provide the necessary materials for the construction, maintenance, and operation of pipelines, storage tanks, power plants, transmission towers, and electrical grids. Their strength, durability, and resistance to corrosion make them an ideal choice for withstanding the demanding conditions of the energy industry, thereby ensuring a reliable and efficient energy supply to meet the growing needs of society.

- Q: How are steel coils used in the production of steel springs?

- Steel coils are used in the production of steel springs as they serve as the raw material for creating the spring's structure. The steel coils are typically shaped and cut into the desired length and diameter to form the spring's body. The coils are then heated and tempered to provide the necessary strength and flexibility required for the spring's function. Overall, steel coils are integral in the manufacturing process of steel springs, providing the base material from which springs are formed.

- Q: What are the dimensions of steel coils used in bridge construction?

- The dimensions of steel coils utilized in the creation of bridges can fluctuate depending on the precise requirements of the bridge undertaking. However, in general terms, the dimensions of steel coils used in bridge construction typically fall within the range of 0.5 to 1 inch in thickness and 36 to 72 inches in width. The length of the coils may also differ, but is commonly around 20 to 40 feet. These dimensions enable the production of various fundamental structural elements, such as beams, columns, and plates, which are indispensable for bridge construction. It is noteworthy that the dimensions may vary based on the specific design and engineering specifications of the bridge project, as well as the type and load capacity of the bridge being constructed.

- Q: What are the different coating options for steel coils?

- Steel coils have multiple options for coating, each with its own purpose and benefits. Some commonly used coatings for steel coils include the following: 1. Galvanized Coating: Steel coils are immersed in molten zinc, resulting in a zinc layer on the surface. This coating offers excellent corrosion resistance and protects against rust. It is ideal for harsh environments and moisture exposure. 2. Galvannealed Coating: This coating combines galvanizing and annealing processes. After galvanizing, the steel coils are annealed to create a zinc-iron alloy layer. Galvannealed coating provides enhanced paintability, weldability, and corrosion resistance. 3. Aluminum-Zinc Alloy Coating: Also known as Galvalume, this coating involves applying an aluminum-zinc alloy to the steel coils. It offers excellent corrosion resistance and heat reflectivity, making it suitable for roofing, siding, and automotive parts. 4. Organic Coatings: These coatings are typically applied as a top layer over a base coat of galvanized or galvannealed coating. Examples include paints, lacquers, and powder coatings. Organic coatings provide additional protection against corrosion, UV rays, and abrasion while enhancing the aesthetics of the steel coils. 5. Chromate Conversion Coating: This coating is commonly used as a pre-treatment before applying organic coatings. It improves adhesion between the steel surface and the organic coating, ensuring better corrosion resistance. The choice of coating depends on factors such as the intended application, environmental conditions, desired appearance, and budget. Manufacturers and end-users should carefully consider these factors to select the most suitable coating option for their specific requirements.

- Q: Hello. right now i have been playing electric and acoustic guitar for 6 years. I currently became very interested in learning the pedal steel guitar. I will be teaching myself so is it really hard to learn? Are there a lot of songs online that could give me tabs? Basically im asking if it is worthwhile to spend a lot of money. I dont want it if there are only 3 songs im gona learn. im up for the challenge im just curious how hard it was to learn. thanks for your help.

- The okorder /... Beware of eBay deals unless you know what you're buying. To start, you should get a 10-string single neck with 3 pedals and 4 levers. Some of the student models don't have as many levers and aren't capable of all the changes you need. Stay away from the ShoBud Maverick...you'll outgrow it in a couple of months. Often it makes more sense to buy a used professional model...you'll eventually need one, and they hold their value better than a student model. You'll also need a volume pedal, bar, thumb and finger picks. For now, your guitar amp will be ok. Playing the guitar: There are several tunings and lots of different combinations of levers, but the basic guitar is a 10 string E9 tuning. It's almost an open E but with a few extra notes. The pedals and levers raise and lower the pitch of selected strings. Chord changes are made by moving the bar and pressing pedals and levers. The volume pedal helps you swell and sustain notes. Steel has it's own unique tablature which reflects all these changes. If you have any other questions, feel free to email me or just join the PSG forum and ask there.

- Q: I have an old classical guitar, which uses nylon strings. ive never really liked the sound produced by the nylon, so im curious if you can use a classical guitar with acoustic guitar steel strings. thanks!

- NO ! NO! NO! Do not put steel strings on a classical guitar!! The increased tension can actually damage the guitar by causing the top to warp and can eventually pull the bridge right off of the guitar! I have seen it happen more than once! Ignore the other post, they are wrong! Classical guitars are designed to use nylon strings only!

- Q: How are steel coils used in the manufacturing of heat shields?

- Steel coils are used in the manufacturing of heat shields to provide a durable and sturdy base material that can withstand high temperatures. The coils are formed into a specific shape and then coated with heat-resistant materials to create a protective barrier against heat and flames.

Send your message to us

Prime Hot Rolled Coil HR Steel Coil China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords