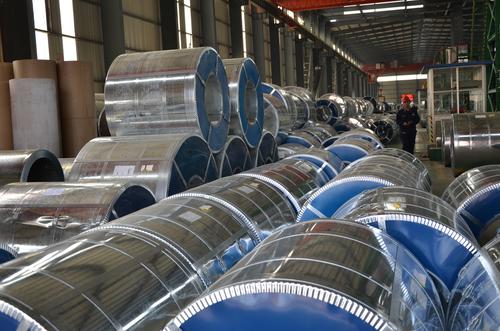

galvanized steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) Quality Standard & Grade: JIS G3302, SGCC / ASTM 653M CQ/ EN10142 DX51D+Z

2) Thikness tolerance: +/-0.02mm Width tolerance:+/0.02mm

3) Zinc coating weight: 50g/m2

4) WEIGHT OF PER COIL: 3-5MT

5)Technology: cold rolled

6) Surface of Product: regular spangle / big spangle/ small spangle; Surface Treatment: chromated , non oiled, skin passed

7) Packing: export standard packing,packed with moisture resistant paper and metal

wrapping,securely tied for export,on metal skids7) Country of Origin :

SIZE:0.27*750

- Q: How are steel coils used in the production of steel rings?

- Steel coils are used in the production of steel rings as the primary raw material. The coils are unrolled and cut into smaller sections, which are then shaped and welded together to form the circular shape of the steel rings.

- Q: What are the different types of steel coil grades and specifications?

- There are several different types of steel coil grades and specifications, including hot rolled, cold rolled, galvanized, and stainless steel coils. Each type has its own unique properties and uses. Hot rolled coils are produced at high temperatures and are commonly used in construction and manufacturing applications. Cold rolled coils are produced at lower temperatures and have a smoother finish, making them suitable for applications that require a higher level of precision. Galvanized coils are coated with a layer of zinc to protect against corrosion, while stainless steel coils contain a high percentage of chromium for added durability and resistance to corrosion. Overall, the choice of steel coil grade and specification depends on the specific requirements of the project or application.

- Q: What is the role of steel coils in the manufacturing of agricultural machinery?

- Steel coils are used in the manufacturing of agricultural machinery to provide strength, durability, and structural integrity to the equipment. They are typically used to form the main body and framework of the machinery, ensuring it can withstand heavy loads, harsh environments, and repetitive use. Additionally, steel coils are often used to fabricate specific components, such as blades, cutting edges, and structural supports, which are crucial for the proper functioning of agricultural machinery in various farming operations.

- Q: How are steel coils handled during loading and unloading?

- Steel coils are typically handled using cranes or forklifts during loading and unloading processes. They are carefully lifted and secured onto trucks or ships using special lifting attachments, and then securely fastened to prevent any movement or damage during transportation. When being unloaded, the coils are carefully lifted and placed onto a designated storage area or directly onto the production line, ensuring proper safety measures are followed to prevent accidents and maintain the integrity of the coils.

- Q: How are steel coils used in the production of steel knobs?

- Steel coils are used in the production of steel knobs by being uncoiled and fed into a stamping press, where the steel is formed into the desired knob shape. This process allows for efficient mass production of steel knobs with consistent quality and strength.

- Q: for instance Cr-Ni steeldoes this refer to plated steel or a uniform mixture

- stainless steel is an alloy normally iron with additions of C, Mn, Ni, Cr, and Nb - amounts added depend on properties required. Corrosion resistance is due to a very thin but dense layer of chromium oxide which forms at the surface and prevents further attack. Ordinary steel on the other hand becomes coated with a porous layer of iron oxide(rust) through which the atmosphere can pass and cause further corrosion.

- Q: Can steel coils be coated with phosphorescent materials?

- Yes, steel coils can be coated with phosphorescent materials. Phosphorescent coatings can be applied to steel coils to create a glowing effect in low-light conditions.

- Q: What are the different types of steel coil slitting machines?

- There are several different types of steel coil slitting machines, including rotary shear slitting machines, loop slitting machines, and tension slitting machines. Each type has its own unique features and advantages, but they all serve the purpose of cutting steel coils into narrower strips.

- Q: Why are steel saucepans and tea kettles covered with copper on the outside and the bottom? what r the goals of having high-quality pans that are thick and tea kettles that are thin walled?

- The issue is heat conduction. Copper trasferrs heat rapidly and therefore ensures uniform heat around the base or sides of teh pot. The thick walls can be two different purposes. Sometimes the steel is made in layers for the purpose of providing insulation. If a pot insulates heat then the heat will transfer in a steady manner and the need for constant fuel heat is reduced. Thus, if I want to simmer and can store some of the heat in the pot itself then I know it will transfer slowly because it has to go through the layers first. Secondly, the layers will transfer heat between them allowing for uniform heating and this avoids hot spots. Wash you pots with an acid. Lemon will clean copper very nicely. If you have to scrub then heat gently and use salt or baking soda as an abrasive. With a tea kettle you do not care about heat conduction past the point of the boil. when the boil arrives the job is done.

- Q: Why is the steel tape tape head not fixed?

- There are better tape measures, heads and magnets. For measuring steel objects, one can operate long distances.

Send your message to us

galvanized steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords